Badger Meter Flow-Alert Reed Switch User Manual

Page 15

Form #04-VAM-UM-00229 09/12

Page 15

9. Reassemble spring, then

piston/magnet assembly and

retaining ring into cartridge.

10. Gently push cartridge

assembly into housing while

holding the magnetic flow

indicator in position.

11. Install metering cone/spider

plate assembly, retaining

spring, and secure with inlet

fitting.

12. Reinstall meter to the line.

Reconnect electrical power.

LPM

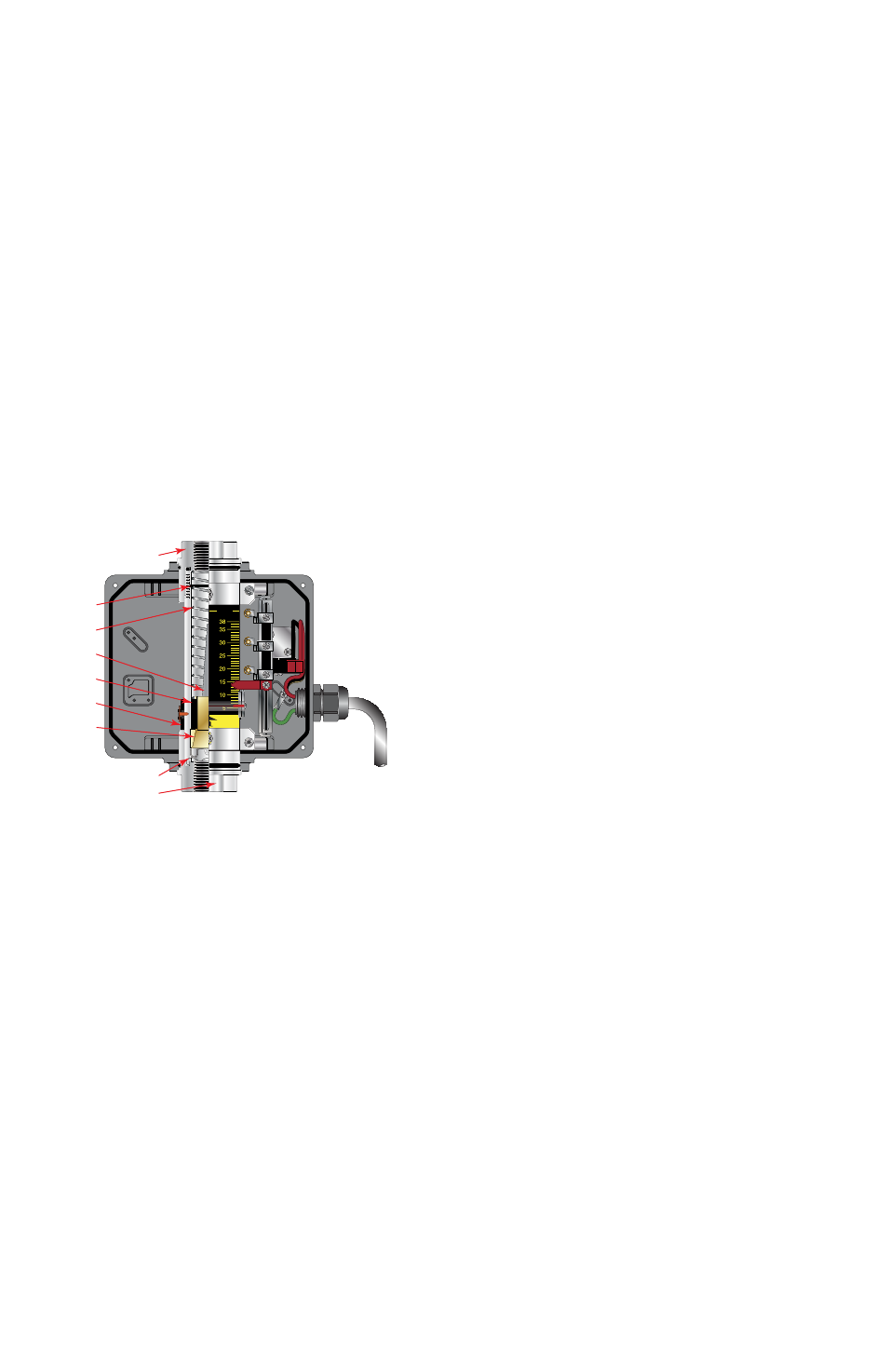

[1] - BODY

[2] - CAP

[3] - CONE ASSEMBLY

[4] - PISTON

[5] - INNER MAGNET

[6] - INDICATOR MAGNET

[7] - RETAINIGN RING

[8] - WAVE SPRING

[9] - METER SPRING

[1]

[9]

[5]

[6]

[4]

[7]

[3]

[8]

[2]

FIGURE 15 - CARtRIDGE

CoMPoNENtS

Quick Re-Coupling

This piston-type variable area flow

meter is inherently less sensitive

to shock and vibration than other

variable area designs. The unique

magnetic coupling also eliminates

the need for mechanical linkages

that can wear or loosen over the

functional life of the meter.

However, on occasion, a pressure

spike or extreme flow surge can

cause the piston to move at such

rapid speed that it disconnects the

piston magnet and the external

indicator ring. If this occurs, use one

of these procedures to re-couple

the magnet and the external indica-

tor ring:

• If the system permits, simply

change flow rate from “no

flow” to “full flow” allowing

the moving piston to

magnetically re-couple to the

indicator ring.

• Remove cover and manually

re-attach external flow

indicator to internal magnet/

piston assembly.

• For rigorous cyclical

applications where de-

coupling may occur

frequently, consult the

technical services staff for

further recommendations.