Wiring and starting an amuract control valve – Warren Controls AmurAct Actuator Linkage and Motor User Manual

Page 6

6

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

IOM_AA_RevH_0413

O

N

1

2

3

4

5

Rotatio

n

: C

W

Input

in

Vdc

Feedb

ack

in

m

A

F

ail sa

fe

return

a

t

0º

Specia

l,

see

belo

w

Potentiomete

r

Dip

switc

h

Reset

butto

n

LED

T

er

m

in

al

C

lu

tc

h

H

ig

h

vo

lta

ge

term

in

al

T

B

4

RE

TU

RN

HOT

/L

IV

E

F

us

e

1

2

3

4

5

TB

1

O

N

1

2

3

4

5

D

S

1

Dip sw

it

ch settings

O

N

1

2

3

4

5

Rotatio

n

: CC

W

Input

in

mA

Feedb

ack

in

Vd

c

F

ail

sa

fe

re

turn

a

t

90

º

Spec

ia

l,

see

bel

ow

Fac

to

ry

default

Special

(d

ip

#

5

)

5

Li

near

li

ft

Anal

og

inp

ut

5

Normal

Anal

og

input

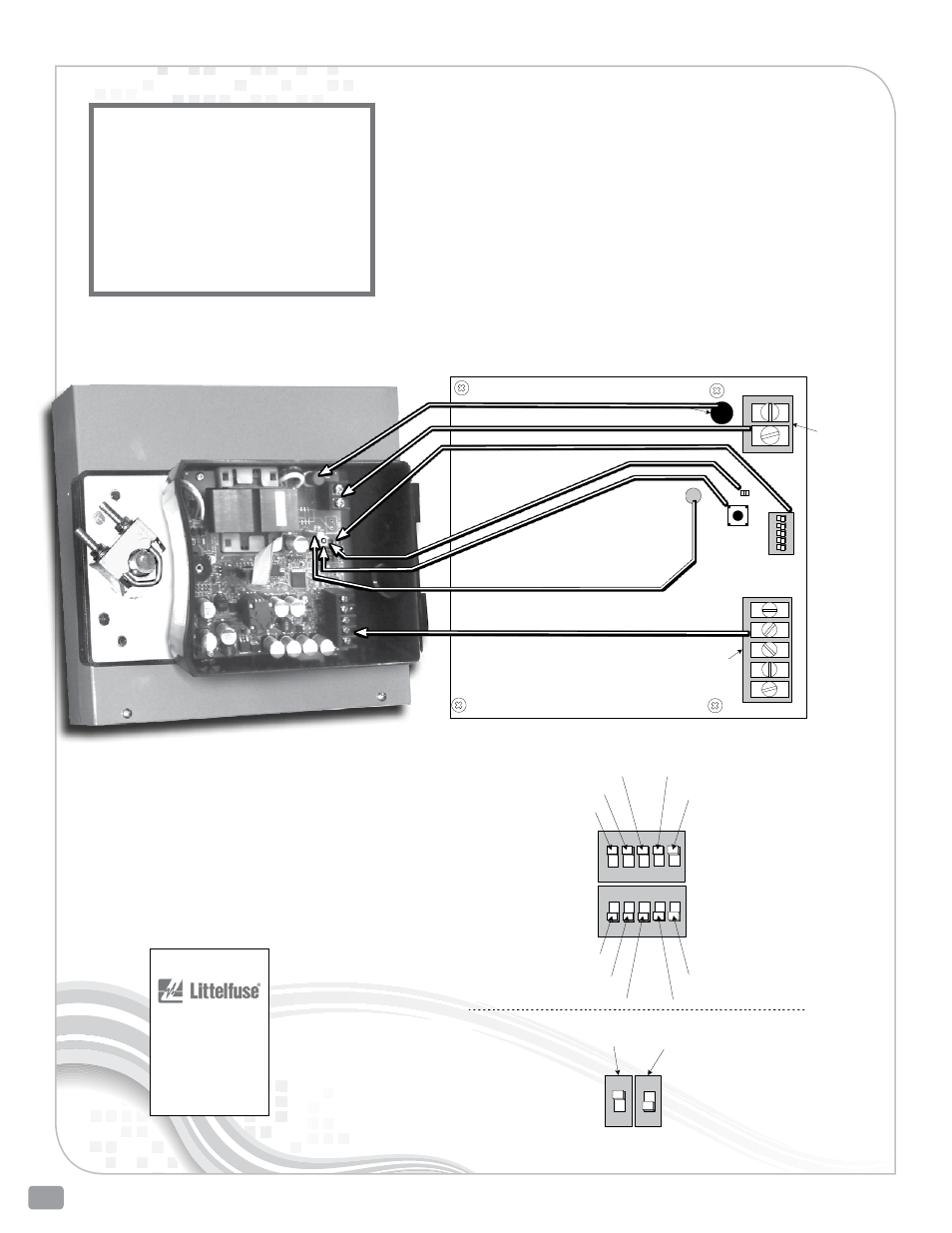

WIRING AND

STARTING AN

AMURACT

CONTROL VALVE.

This applies to all AmurAct models.

Remove the screw from the black mo-

tor cover and refer to the following

circuit board diagrams for the des-

ignated terminations and switches.

Field wiring should be of sufficient

size and insulation rating to be in ac-

cordance with local codes, ordinances

and standards for safety. The motor

draws 30vA (either model) at full load,

while start up power consumption is

50vA. The Power Supply wires if not

specified should be a minimum of 18

AWg and at that gauge should not ex-

ceed 100 ft. from the transformer. For

longer lengths, use 16 AWg wire. The

input signal and feedback may use

standard instrument wire of 24 or 26

AWg. Do not use rigid conduit.

* Fuse is a

part number

3720315041

315 mA

Slow Blow with

T41 terminations

Contact the factory at (610) 317-0800

before attempting to reconfigure or

reposition an AmurAct actuator.

Improperly rotating the linkage on the

valve bonnet adversely affects linkage

calibration, can result in seat damage

and/or operational failure; and

will void warranty coverage.

ON

1 2 3 4 5

Rotation: CW

Input in Vdc

Feedback in mA

Fail safe return at 0º

Special, see below

Potentiometer

Dip switch

Reset button

LED

Terminal

Clutch

High voltage terminal

TB4

R

E

T

U

R

N

HO

T

/L

IV

E

Fuse

1 2 3 4 5

TB1

ON

1 2 3 4 5

DS1

Dip switch settings

ON

1 2 3 4 5

Rotation: CCW

Input in mA

Feedback in Vdc

Fail safe return at 90º

Special, see below

Factory default

Special

(dip #5)

5

Linear lift

Analog input

5

Normal

Analog input

TB1

Non-linear lift

Clutch

LED

Reset

Button

Dip Switch

Terminal

TB5

(2-way only)

(2-way or 3-way)