Caution – Warren Controls AmurAct Actuator Linkage and Motor User Manual

Page 10

10

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

IOM_AA_RevH_0413

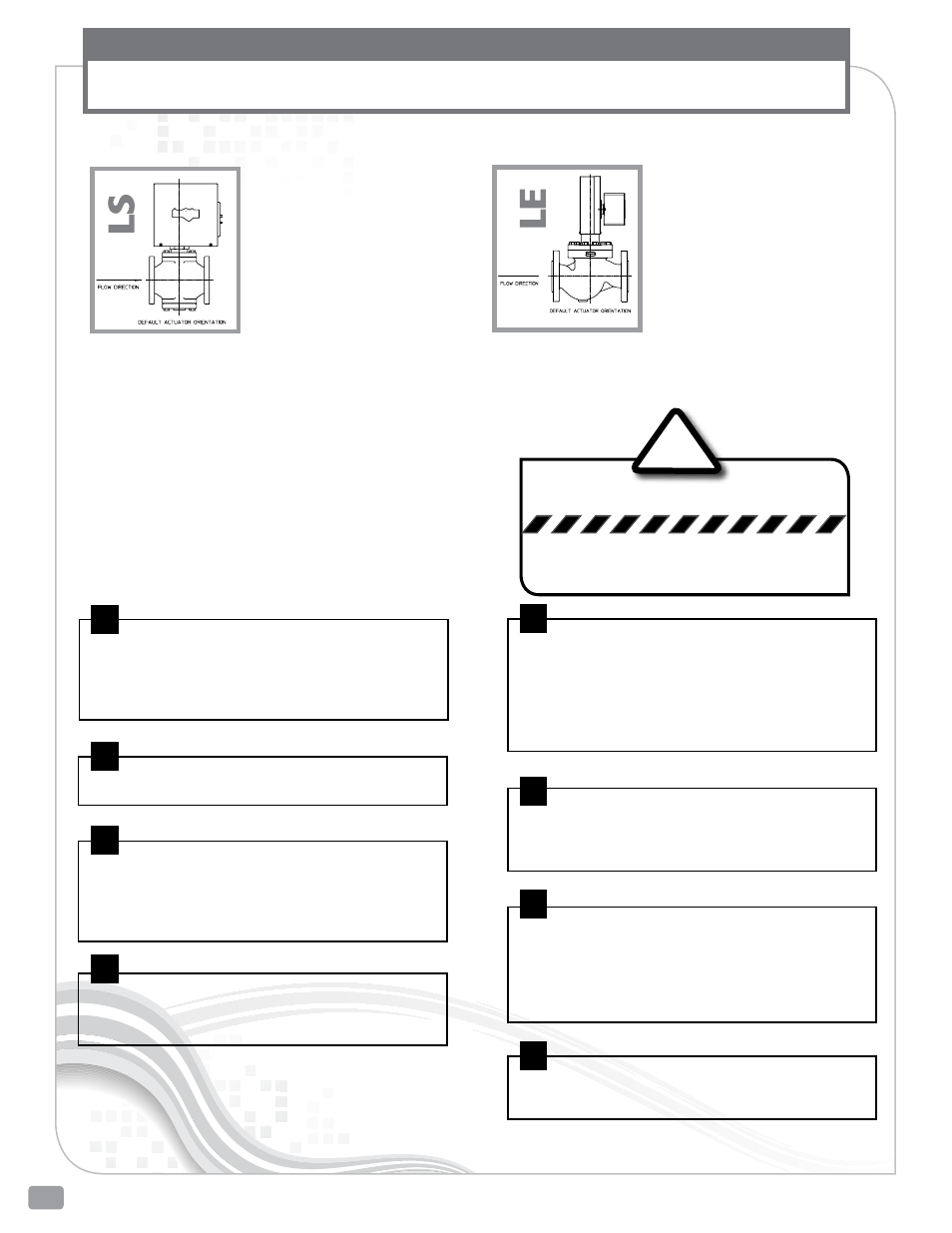

The AmurAct is available with two

versions of Linkage. The standard

version or LS linkage has the mo-

tor situated directly behind the

linkage assembly with the Amu-

rAct actuator unit oriented parallel

to the pipeline This configuration

of the linkage is suitable for pro-

cess fluids up to 250F (steam to

15 PSIg) when the pipeline and

valve are not insulated, or up to

340F (steam to 100 PSIg) when the pipeline and valve are

insulated.

For higher temperature applica-

tions or for when insulation is not

available the higher temperature

linkage can be used. This is capable

of operating up to the valve rated

temperature, without regard to in-

sulation. For temperatures above

500F this may require the use of

the optional extension bonnet as

well. In this version, the motor is

oriented 180° away from the stan-

dard orientation, and the entire assembly is mounted per-

pendicular to the valve and pipeline, avoiding convected

heat from the valve and process piping, ensuring safe, reli-

able operation.

REMOVING AN AMURACT

MOTOR

1

Shut the isolation valves both upstream and downstream of

the AmurAct control valve. If the control valve is not isolated,

line pressure can open the valve and move the linkage when

the motor is removed.

2

Turn off power to the motor and controller.

3

Remove the black motor cover and dissipate Enerdrive

energy by cycling dipswitch #2 in 20-second intervals until

the motor no longer runs. Return dipswitch #2 to its ON

position (Fail Shut).

4

Remove the front safety shield by removing the two screws

from the lower edge of the AmurAct linkage.

5

De-clutch the motor by depressing the brass pin located

in the center of the circuit board as shown on page 6 and

manually rotate the CRANk to its counter-clockwise end

of travel position, as defined in specific linkage calibration

procedures. Install a c-clamp to hold the CRANk in that

position.

6

If the same motor is to be reinstalled, proceed to step 7. If

it is to be replaced, label field wires for reconnection, then

disconnect and remove them.

7

Loosen the two 10 mm hex nut on the motor output clamp u-

bolt. This is best done with a long socket or box end wrench.

Nuts are very tight. (It may also be necessary to loosen the

kep nut and loosen or remove the anti-rotation screw located

at the foot of the motor.)

8

Remove the motor. Review linkage calibration on pages 13-

15 to verify linkage is calibrated and valve stem nuts are tight.

if iT iS neceSSaRy TO Re-POSiTiOn amuRacT On The valve call The facTORy aT

610-317-0800 fOR PROceduRal aSSiSTance. failuRe TO dO SO will vOid The waRRanTy cOveRage.

TO Re-ORienT The amuRacT On The valve cOnSulT facTORy

STANDARD VS hIGh TEMPERATURE LINkAGE

!

CAUTION

Do not de-clutch the actuator when power is on.

Irreparable damage to the gear train will occur!