Theory of operation, Amuract linkage – Warren Controls AmurAct Actuator Linkage and Motor User Manual

Page 3

3

AmurAct

IOM_AA_RevH_0413

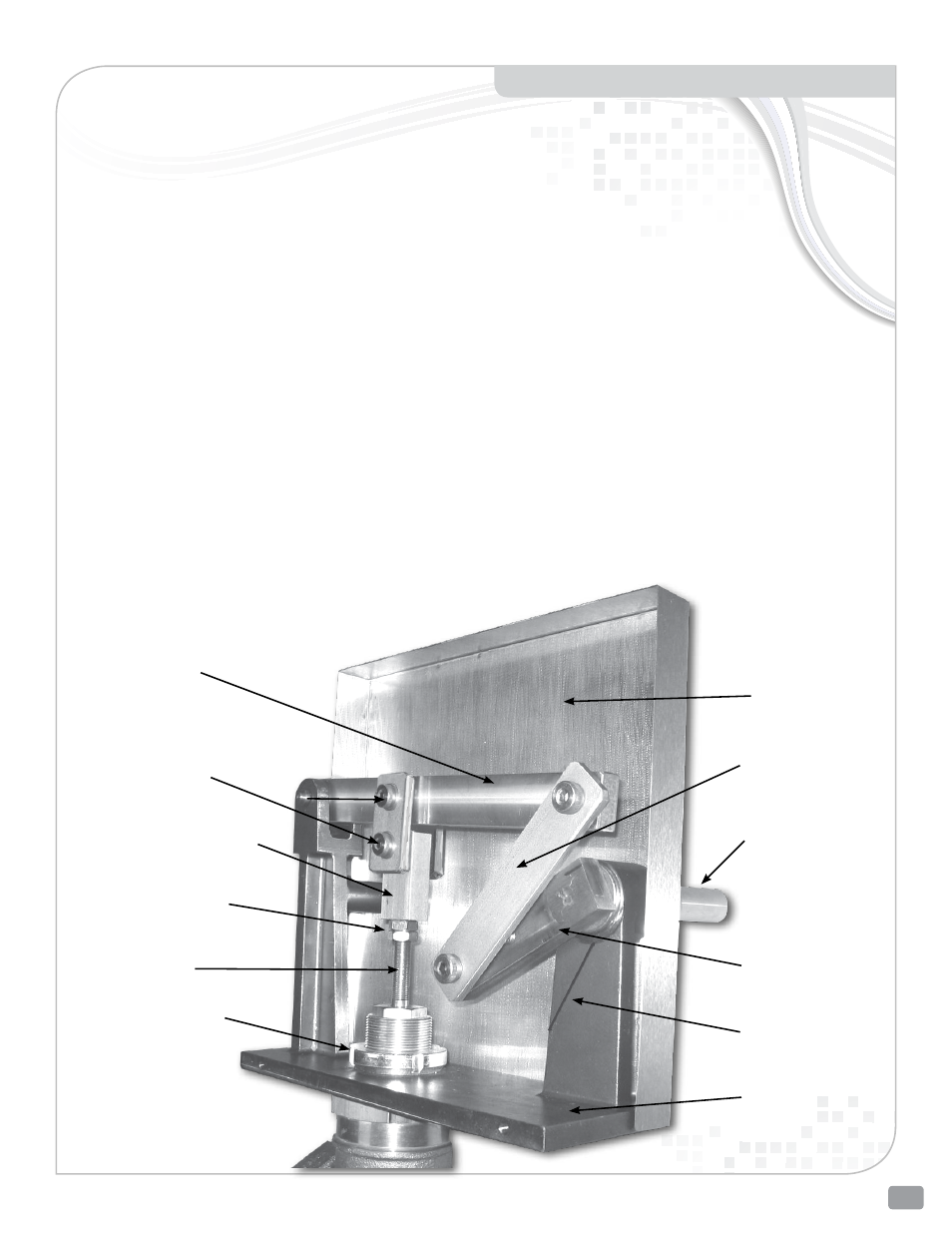

LEvER

STEM

CONNECTOR

vALvE

STEM

LINkAgE

LOCkNUT

REAR SAFETy

SHIELD

LINk

INPUT

SHAFT

CRANk

BENCHMARk

LINkAgE

BASE

AmurAct Linkage

(front Safety Shield Removed)

Refer to page 2 and below for identification and location of compo-

nents and parts.

Four AmurAct

MOTORS are available: the F3 and F5 produce 120

pound-inches of torque and the F4 and F6 produce 240 pound-inch-

es. A

MOTOR is selected according to the valve type and size, the

differential pressure against which the valve must operate, and the

power source that is available. Consult Product Specifications for ad-

ditional information on motor selection.

Each motor contains an internal Enerdrive® energy source to run the

motor to a fail-safe valve position if operating power is lost. An ad-

vanced AutoStroke feature apportions the control signal over the ac-

tual range of valve movement for increased accuracy; and provides

“soft stops” at both ends of travel to extend operating life. See page 6

for location of the Reset/Autostroke pushbutton.

The

MOTOR applies rotary motion and rotational force to the INPUT

SHAFT of the AmurAct LINKAGE by means of the SHAFT CLAMP.

The

CRANK is welded to the INPUT SHAFT and rotates with it.

Clockwise

CRANK rotation is translated by the LINK and causes the

LEVER to rotate counterclockwise (upward) about the fixed pivot at

its left end (as shown below).

A

STEM CONNECTOR is threaded onto the valve stem and attached

to the

LEVER by two connecting links. Upward movement of the LE-

VER draws the VALVE STEM upward. The articulated link connec-

tion reduces side loading on the valve stem packing. Raising the stem

of a two-way valve opens it. Raising the stem of a three-way valve

opens the lower (L) port and shuts the upper (U) port. When the

MO-

TOR reverses direction, the lever is drawn downward and the valve

stem is pushed downward, reversing the control valve action.

When the AmurAct linkage has been calibrated, the

BENCHMARK

indicates the position of the

CRANK when the valve plug makes

contact with the valve seat. Further counterclockwise rotation of the

CRANK exerts seating force onto the valve plug to produce very tight

closure. On a two-way valve with ¾” stem travel, motion stops when

the

CRANK and LINK are aligned with each other, perpendicular to

the

LEVER. This is the lockup position, and is maintained by the Amu-

rAct linkage without sustained

MOTOR torque.

Factory default settings call for an increasing 2-10 volt or 4-20 mAdc

signal to open the control valve. Therefore, loss or interruption of the

control signal will cause the two-way valve to shut, or the lower (L)

port of a three-way valve to shut. Similarly, loss of operating power

will activate the Enerdrive fail-safe system to drive the AmurAct link-

age to the fail-safe position. Upon restoration of operating power,

AmurAct returns to normal operation after the Enerdrive fail-safe en-

ergy source is fully recharged, typically 30 seconds or less ... with no

operator action required.

STEM CONNECTOR

SHOULDER

SCREW

STEM

JAM NUTS

ThEORy OF OPERATION