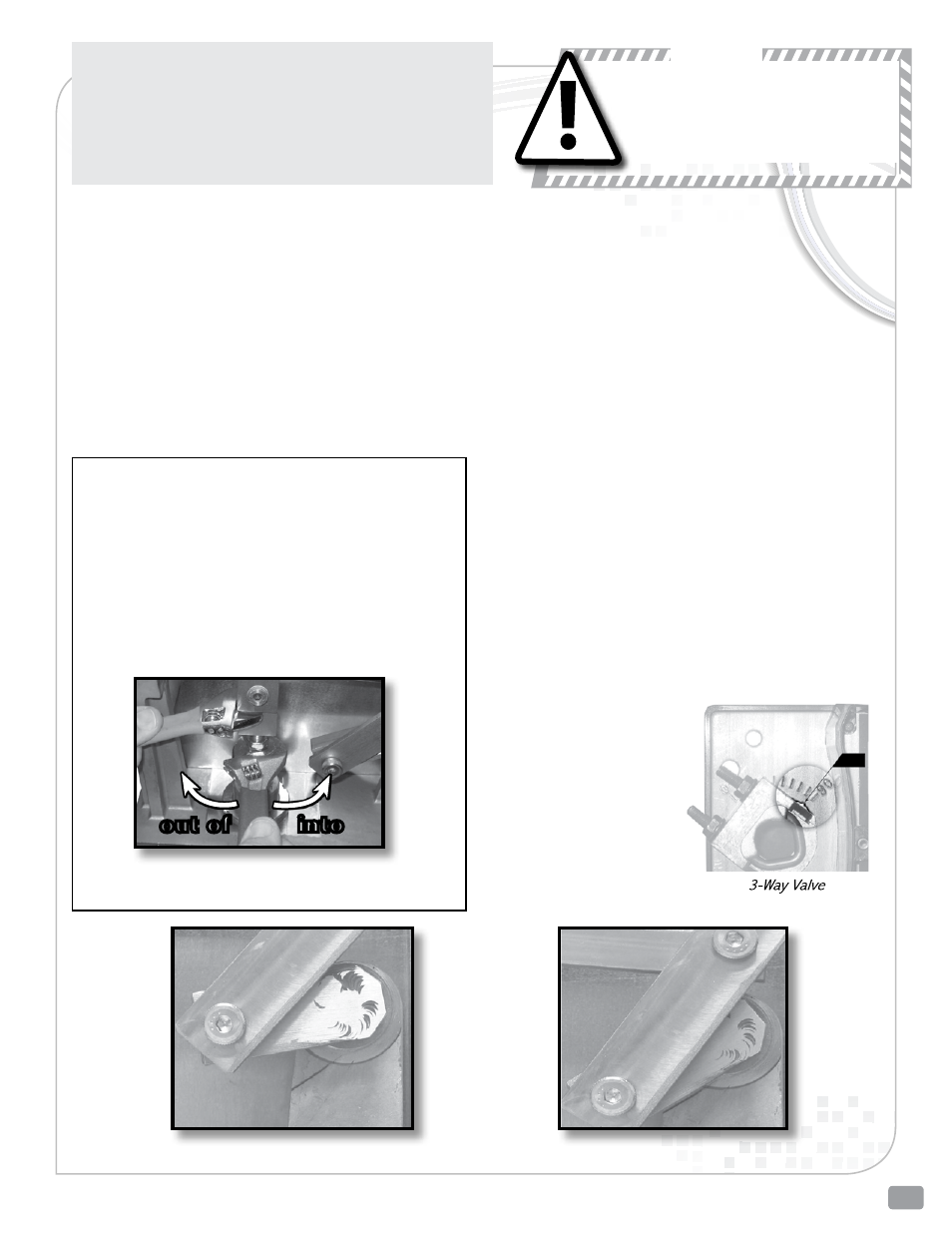

Into out of – Warren Controls AmurAct Actuator Linkage and Motor User Manual

Page 15

15

AmurAct

IOM_AA_RevH_0413

1.

Beginning with a linkage properly oriented, securely

fastened to the valve bonnet and loosely assembled to

the valve stem, manually operate the linkage to raise the

valve stem. Observe the benchmark scribed into the front

face of the crank support column.

BENcHMARK

cALIBRATED

4.

Carefully loosen the stem nuts from each other and

move the upper nut upward into contact with the stem

connector block. Using a second wrench to keep the block

from rotating, tighten the nut securely against the block.

This tightening will lengthen the stem connection assembly

and allow less crank rotation to the plug/seat contact point.

5.

Repeat step 2 (above). If the crank stops PRECISELY at

the benchmark (denoting proper calibration), tighten the

second stem nut against the first, then repeat step 2 once

more.

6.

If the crank does not stop PRECISELY at the benchmark

after completing step 5, repeat this procedure from step 3,

appropriately lengthening or shortening the stem assembly

in small increments.

7.

After precise calibration is complete, push the crank

firmly against its support column to fully extend the linkage

input shaft.

8.

Calibrate and install the motor as instructed on Page 11

of this manual. The proper motor calibration point for this

version is approximately 85

degrees as indicated on the

motor clamp position scale.

The remaining motor travel

exerts valve close-off force.

Remember to press the mo-

tor RESET pushbutton after

installation and calibration

are complete and the motor

is energized, but before the

system is placed into ser-

vice. (Verify Dip Switch #5

is set to off)

NOTE that the valve stem and plug have been raised prior to turning the

stem.

into

out of

2.

gently lower the valve stem and note the position of

the crank relative to the benchmark when the plug makes

contact with the valve seat. Exert just enough force on

the crank to take up any looseness in the linkage pivots.

3.

Lower and tighten the two stem nuts together. This

provides a means to grip and rotate the valve stem after

lifting the plug from its’ seat, to thread the stem into or

out of the stem connector. Threading the stem into the

connector shortens the assembly and allows the crank to

move further counterclockwise. Threading the stem out

of the connector lengthens the assembly, allowing less

counterclockwise rotation. Perform this sensitive into or

out of adjustment until the crank stops 2 to 3 degrees

PAST the benchmark. REPEAT THE POSITION CHECk IN

STEP 2 AFTER EACH ADJUSTMENT.

Version C:

three-way AmurAct control valves having 3/4” stem travel. Small (1/2”-1”)

AMB-30 valves have stem travel = 9/16”.

OVERVIEW: Calibration of the AmurAct linkage is accomplished by adjusting effective stem

length so the linkage crank is precisely aligned with a benchmark when the valve plug contacts

the valve seat. Precision is necessary, because the remaining crank travel determines how much

force will be applied to the valve plug to achieve tight shutoff. Minor maladjustment can result

in major loss of shutoff capability or overstressing of linkage and valve components. AmurAct

performance is directly related to the accuracy of its’ calibration. Calibration of each version is

different from the others, read and understand the entire procedure before adjust-

ing anything. Call our factory with any questions.

wARNING

The valve stem must be raised when making

stem connector adjustments. Do not turn or

rotate the valve stem while the valve plug

is in contact with the valve seat. “Grinding”

contact will damage the mating surfaces,

adversely affect shut-off capability.