Installation, Product model, Dn250 1 size reduced port ss trim only – Warren Controls PICV Series User Manual

Page 8

8

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

INSTALLATION

Recommended Piping: ANSI 125 Flanges should mate with piping with 125 Lb or 150 Lb

Flat Faced Flanges.

Per ISA Recommended Piping Practices. Control valves perform best with a reasonable

amount of upstream and downstream straight pipe prior to elbows and strainers. The

general specification for this is 16 pipe diameters upstream of straight pipe and 5 pipe

diameters downstream of straight pipe as minimums. However, this is a broad specification

covering all pipe diameters and velocities. Many applications do not have this kind of

space. While more length of straight pipe is desirable, Warren Controls has produced a

table of minimum pipe diameters for use on our PICV. Failure to follow these guidelines

may lead to noticeable vibrations or noise for excessive turbulence in some applications

with significant head pressure. In the unlikely event of excessive noise or vibration, other

remedies like special low noise trim may be available but at the expense of the user or

installer when not following installation guidelines.

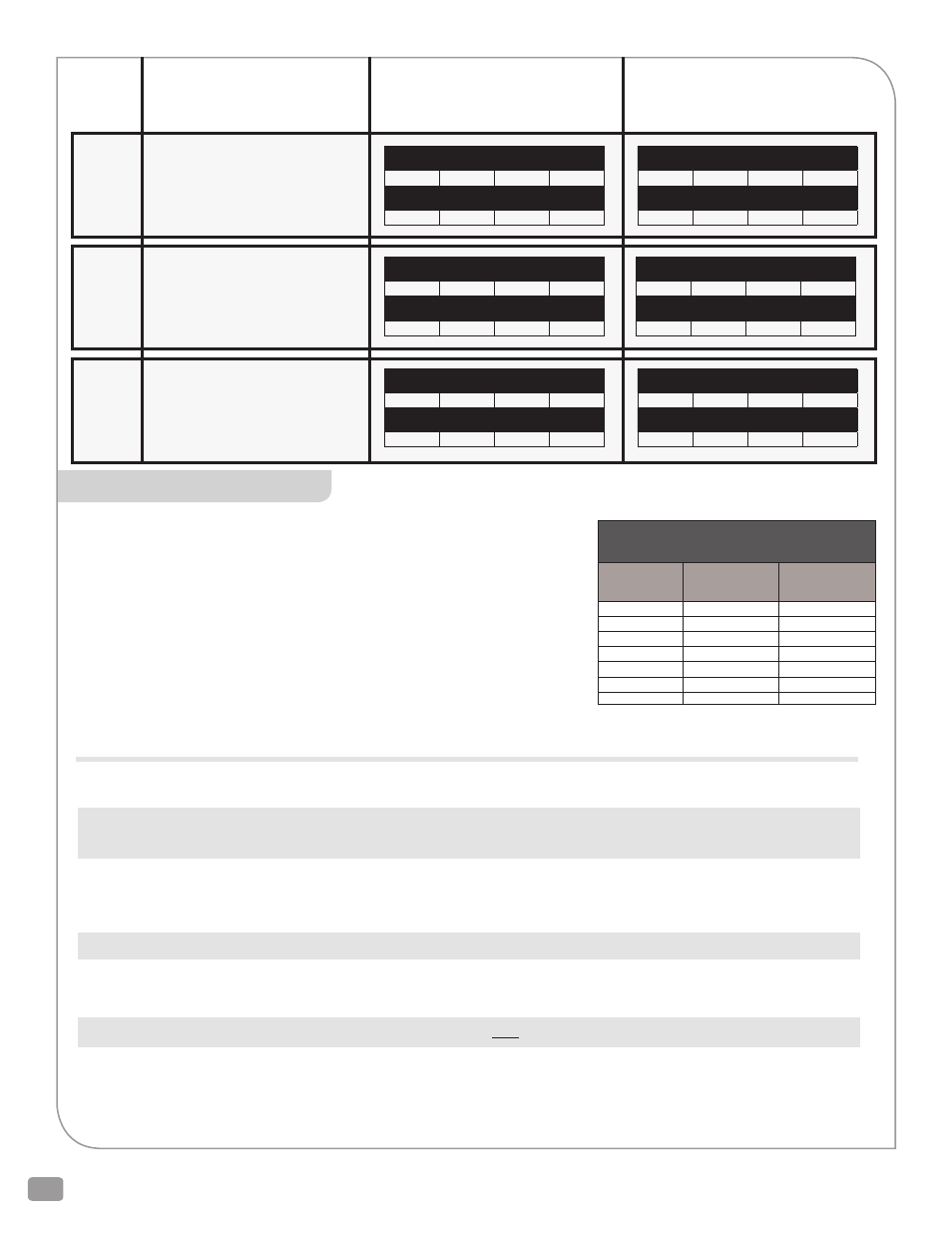

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

FLANGE

PN16

P1222Fx-xxxx-P12Dx-2x

DN250 Standard Port

PN16

P12222S-xxxx-P12Dx-2x

DN250 2 Sizes Reduced Port

SS Trim Only

PN16

P12221S-xxxx-P12Dx-2x

DN250 1 Size Reduced Port

SS Trim Only

The above tables are recommended minimum lengths for good and stable performance. Wherever possible, longer runs of straight pipe

should be used for optimal performance and stability.

• Be sure that the flow medium, ambient temperature and the selected location will not exceed the maximum temperature of the PICV,

actuator, or accessories. Information can be found on the nameplate and product specifications regarding these limits.

• Check PICV for any damage due to improper storage or transportation. Immediately notify your sales organization of any damaged

goods upon receipt. Do not attempt to move or disturb them further so photos may be taken. If the shipping container is noticeably

damaged, refuse receipt as the shipping company should be held liable, until a shipping representative is available to take photos.

• Verify that the PICV is visually in good working order – not bent or cracked.

• Follow good piping practices. Install a bypass around the PICV. Install stop valves in inlet and outlet piping to provide means to isolate

PICV.

• THE PICV SHOULD BE INSTALLED AS A UNIT. THE SEGMENTS SHOULD

NOT BE SEPARATED FOR INSTALLATION.

• Carefully remove the PICV from shipping crate with a portable hoist or crane. The PICV is too heavy for one or even two people to lift

and hand-install depending on size. The Crane or Hoist should use a strap or chain cradle around the central flanges of the two valve

assemblies to raise and maneuver the PICV into position at the pipe flanges. Efforts should be made to avoid damaging the sensing

lines and actuators during this installation procedure.

Set Differential Pressure (BAR)

0.14

0.21

0.29

0.37

Maximum flow (LPS)

66

81

95

107

Set Differential Pressure (BAR)

0.39

0.45

0.5

0.55

Maximum flow (LPS)

110

118

125

131

Set Differential Pressure (BAR)

0.14

0.21

0.29

0.37

Maximum flow (LPS)

76

92

109

123

Set Differential Pressure (BAR)

0.39

0.45

0.5

0.55

Maximum flow (LPS)

126

135

143

150

Set Differential Pressure (BAR)

0.14

0.21

0.29

0.37

Maximum flow (LPS)

86

106

124

140

Set Differential Pressure (BAR)

0.39

0.45

0.5

0.55

Maximum flow (LPS)

144

155

163

171

PICV Minimum Lengths of

Straight Pipe

PICV Size

Upstream

Straight Pipe

Downstream

Straight Pip

2 ½” (DN65)

16” (40.64 cm)

12” (30.48 cm)

3” (DN80)

16” (40.64 cm)

12” (30.48 cm)

4” (DN100)

16” (40.64 cm)

12” (30.48 cm)

5” (DN125)

24” (60.96 cm)

12” (30.48 cm)

6” (DN150)

32” (81.28 cm)

12” (30.48 cm)

8” (DN200)

36” (91.44 cm)

14” (35.56 cm)

10” (DN250)

40” (101.6 cm)

16” (40.64 cm)