Switch 8: factory default off, Direct or reverse acting, Flow characteristic – Warren Controls PICV Series User Manual

Page 17: Selecting the signal

17

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

Full Range

Split Range

0 - 10 vdc

0 - 5 vdc 5 - 10 vdc

2 - 10 vdc

2 - 6 vdc 6 - 10 vdc

0 - 20 ma

0 - 10 ma 10 - 20 ma

4 - 20 ma

4 - 12 ma 12 - 20 ma

Split ranges allow two actuators to be operated in sequence from

one full range signal. Proportional signals are programmed with

switches 1 - 5. The actuators are set for floating control by turning

on switch #6. Turning switch #6 on deactivates switches 1 - 5.

Please note the wiring for floating control differs from the wiring for

proportional control.

SELECTING THE SIGNAL

Floating

Switch #6

ON

When switch #6 is on

switches 1-5 are inactive.

Proportional Switch #6

OFF

SIGNAL

SWITCH NUMBER

VOLTS

1

2

4

5

2 - 10

OFF

OFF

OFF

OFF

0 - 10

OFF

ON

OFF

OFF

2 - 6

OFF

OFF

ON

OFF

6 - 10

OFF

OFF

ON

ON

0 - 5

OFF

ON

ON

OFF

5 - 10

OFF

ON

ON

ON

SIGNAL

SWITCH NUMBER

MILLIAMPS 1

2

4

5

4 - 20

ON

OFF

OFF

OFF

0 - 20

ON

ON

OFF

OFF

4 - 12

ON

OFF

ON

OFF

12 - 20

ON

OFF

ON

ON

0 - 10

ON

ON

ON

OFF

10 - 20

ON

ON

ON

ON

DIRECT OR REVERSE ACTING

An increasing signal can either drive the valve stem down

(direct acting) or up (reverse acting).

Reverse Acting Switch #3 ON

Properly selected and sized control valves utilize the default

(OFF) positions for switches #7 & #8.

Contact Warren Controls (Ph: 800-922-0085) before repositioning

either switch.

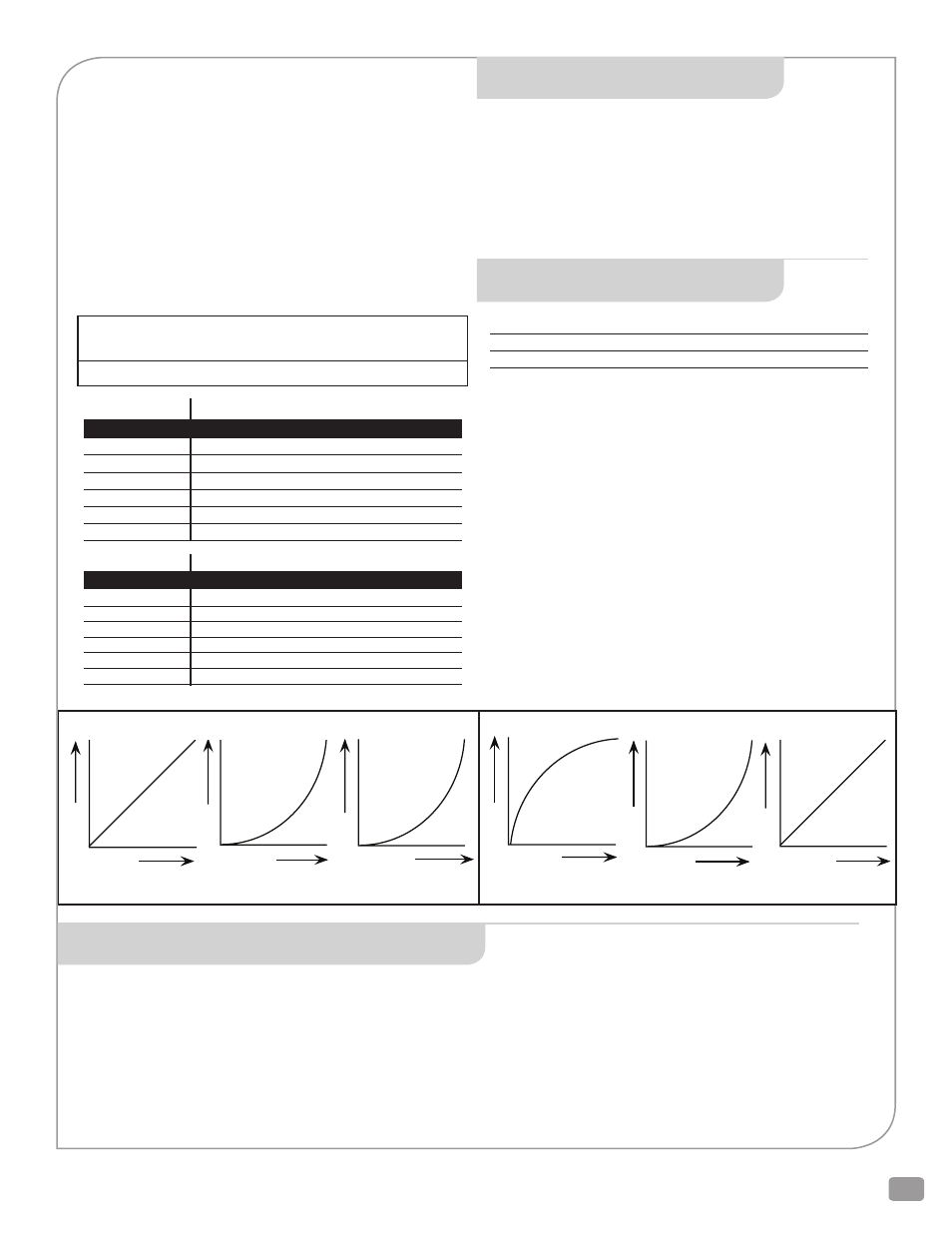

FLOW CHARACTERISTIC:

Change Flow Characteristic Switch #7

IN THE OFF POSITION STEM TRAVEL IS PROPORTIONAL TO CON-

TROL SIGNAL AND DOES NOT ALTER THE FLOW CHARACTERISTIC OF

VALVE. THIS IS THE POSITION SWITCH #7 SHOULD BE IN NORMALLY.

When the stem travel of an actuator is proportional to the control

signal, the shape (flow characteristic) of the valve’s plug determines

the flow. PICV valves have an equal percentage flow characteristic.

An equal percentage valve opens slowly at the start so that 25%

stem travel results in less than 25% flow. When Switch #7 is in the

ON position the stroke is electronically adjusted so that an equal

percentage valve performs as if it had a linear flow characteristic. A

linear valve opens so that 25% stem travel results in 25% flow.

EQUAL PERCENTAGE VALVE & SWITCH #7 OFF

EQUAL PERCENTAGE VALVE & SWITCH #7 ON

NOTE: Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup. For information about them contact

Warren Controls (Ph: 800-922-0085).

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

6

Properly selected and sized control valves utilize the default (OFF) positions for switches #7 & #8. Contact

Warren Controls (Ph: 800-922-0085) before repositioning either switch.

Flow Characteristic:

Change Flow Characteristic

Switch #7

In the OFF position the stem travel is proportional to the control signal and does not alter the fl ow characteristic of the valve. This

is the position this switch should be in normally. In the ON position the stroke is electronically adjusted so that an equal percent-

age valve performs as a linear valve and a linear valve performs as a quick opening valve. Most 2-way control valves have an

equal percentage fl ow characteristic. Usually the stem travel of an actuator is proportional to the control signal and the valve plug

is shaped to adjust the fl ow. An equal percentage valve opens slowly at the start so that 25% stem travel results in less than 25%

fl ow. Mixing valves usually have plugs that are linear on both ports so that the total fl ow through the valve doesn’t change with

the stem position. Switch #7 should be OFF when you use mixing valves. Occasionally, you may want switch #7 to be ON.

If you have an equal percentage valve and you want to control the volume of liquid such as the depth of water in a tank changing

to a linear valve characteristic may work better. Steam heat depends on the quantity of steam per hour condensed. Consequently,

a linear valve may work better. In these cases, turn Switch #7 ON. If you are using a linear valve in one of these applications,

then leave switch #7 OFF.

Direct or Reverse Acting

An increasing signal can either drive the valve stem down (direct acting) or up (reverse acting).

Direct Acting

Switch #3

OFF

Reverse Acting Switch #3

ON

NOTE:

Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup.

For information about them contact Warren Controls (Ph: 800-922-0085).

Equal Percentage Valve & Switch #7 Off

Actuator

Signal

St

ro

ke

Stroke

Fl

ow

Valve

Fl

ow

Valve + Actuator

Signal

Equal percentage Valve & Switch #7 On

Fl

ow

Valve

Stroke

Fl

ow

Valve + Actuator

Signal

Actuator

St

ro

ke

Signal

Flow Coeffi cient

Full Flow

Switch #8

OFF

Reduced Flow

Switch #8

ON

This function only works when switch #7 is off.

Turning switch #8 on reduces the valve stroke and then sets the control signal over the range of the reduced stroke. The result is

that the valve never fully opens and it performs like a smaller valve.

SWITCH 8: FACTORY DEFAULT OFF

The correct position for Switch #8 is OFF.

Do not use the Switch #8 ON. If Switch #8 is ON the valve will not function properly as a PICV.