Dprv actuator instructions, Warning – Warren Controls PICV Series User Manual

Page 28

28

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

PICV SET DIFFERENTIAL PRESSURE

ADJUSTMENT

1. Remove line pressure and isolate PICV valve in piping.

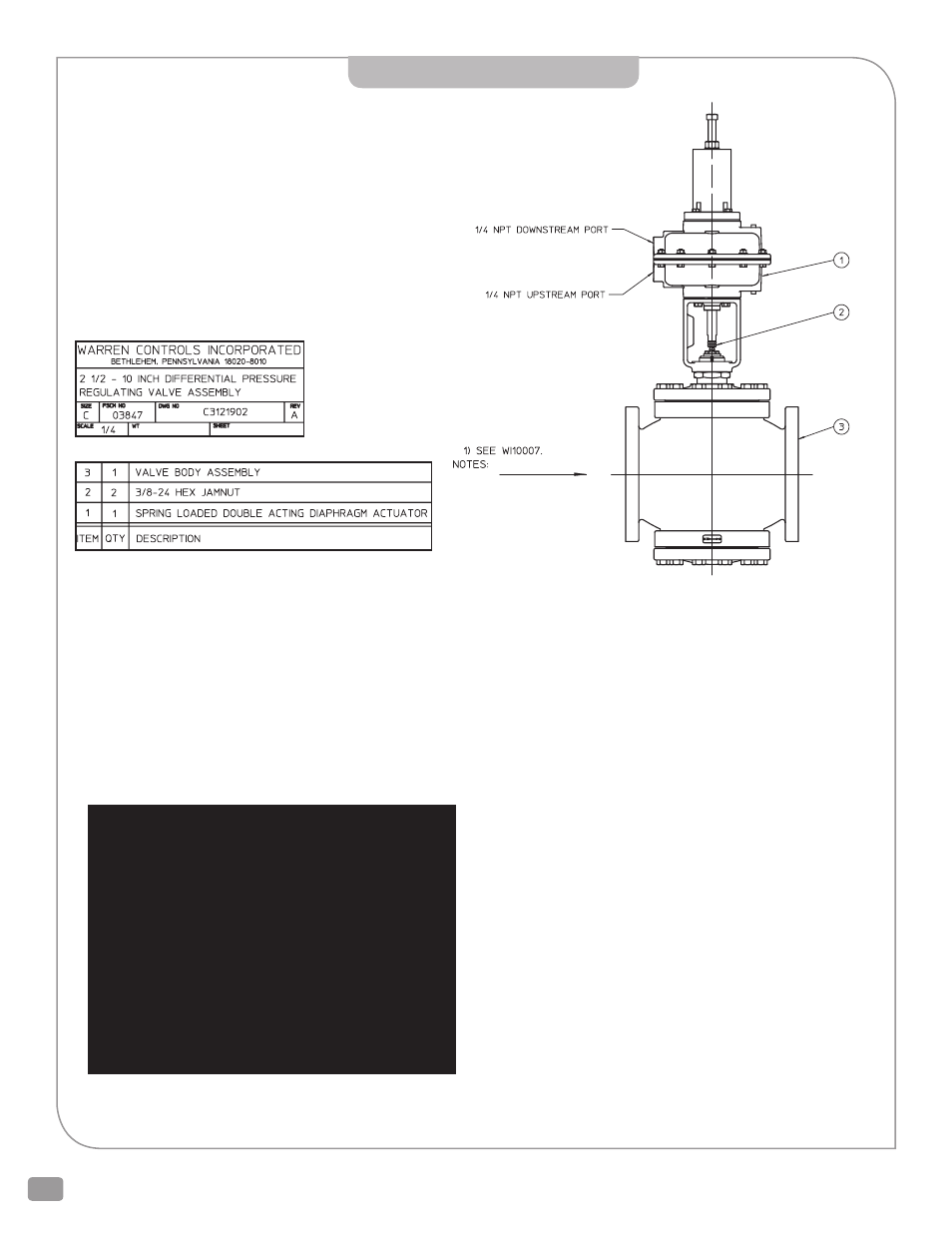

2. Remove upstream port and downstream port pressure sensing

lines from connections on diaphragm actuator (See drawing

C3121902).

3. Connect flexible temporary air connection to upstream port

pressure sensing connection on diaphragm actuator (See

drawing C3121902 for location of upstream port pressure

sensing connection).

4. Use marking pen to place mark on valve stem just above where

it enters the valve.

WARNING:

In Steps 5 thru 10, do not

turn the adjusting screw so it extends more

than 3-3/4 inches (9.53 cm) above the top of

the actuator (more than 26 threads are visible

on the adjusting screw). Doing so may cause the

adjusting screw to separate from the actuator

resulting in damage and personal injury from

the uncontrolled release of pressure inside the

actuator. Be careful not to damage the seal in

the seal washer on the adjusting screw. The

seal may be damaged by excessive turning of

the adjusting screw or by pushing it over the

screw’s threads. If the seal in the seal washer

is damaged the actuator will leak when line

pressure is returned to the valve.

5. Loosen locknut on adjusting screw on top of actuator and

separate from seal washer. Thread locknut only to top of

adjusting screw.

6. Apply air pressure to upstream port pressure sensing connection

equal to desired set differential pressure plus ½ psig (0.034 BAR).

Example: For set differential pressure of 5 psig (0.345 BARG),

apply 5-½ psig (0.379 BARG) to upstream port pressure sensing

connection. If mark made on valve stem in Step 9 moves away

from valve, turn adjusting screw clockwise, looking down on

actuator, until mark returns to its closest point to the valve.

7. Turn adjusting screw slowly counter-clockwise, looking down on

actuator, a ½ turn at a time until mark made on valve stem in

Step 9 just begins to move away from the valve.

8. Reduce air pressure to upstream port pressure sensing

connection to 0 psig (0 BARG) and allow all air to bleed from

actuator.

9. Slowly increase air pressure to upstream port pressure sensing

connection until equal to desired set differential pressure. Mark

made on valve stem should just begin to move away from the

valve when pressure reaches desired set differential pressure.

If mark moves too soon, turn adjusting screw clockwise an

additional ½ turn then repeat Steps 13 and 14. If mark does not

move, turn adjusting screw counter-clockwise an additional ½

turn then repeat Steps 13 and 14. Satisfactory adjustment should

be made within 2 additional full turns of the adjusting screw.

10. Thread locknut on adjusting screw down to top of actuator

and tighten securely against seal washer to create seal against

actuator. If the locknut is not tightened securely the actuator

will leak when line pressure is returned to the valve.

11. Install upstream port and downstream port pressure sensing

lines (See drawing D3121311 (Sizes 2-1/2 thru 4 inch, P2 thru P4)

or C3121900 (Sizes 5 thru 10 inch, P5 thru P1) for orientation of

upstream port and downstream port pressure sensing lines).

12. Return line pressure to valve.

DPRV

ACTUATOR

INSTRUCTIONS

C3121902