On-off switch, Wiring pcb, Debugging/self-stroking – Warren Controls PICV Series User Manual

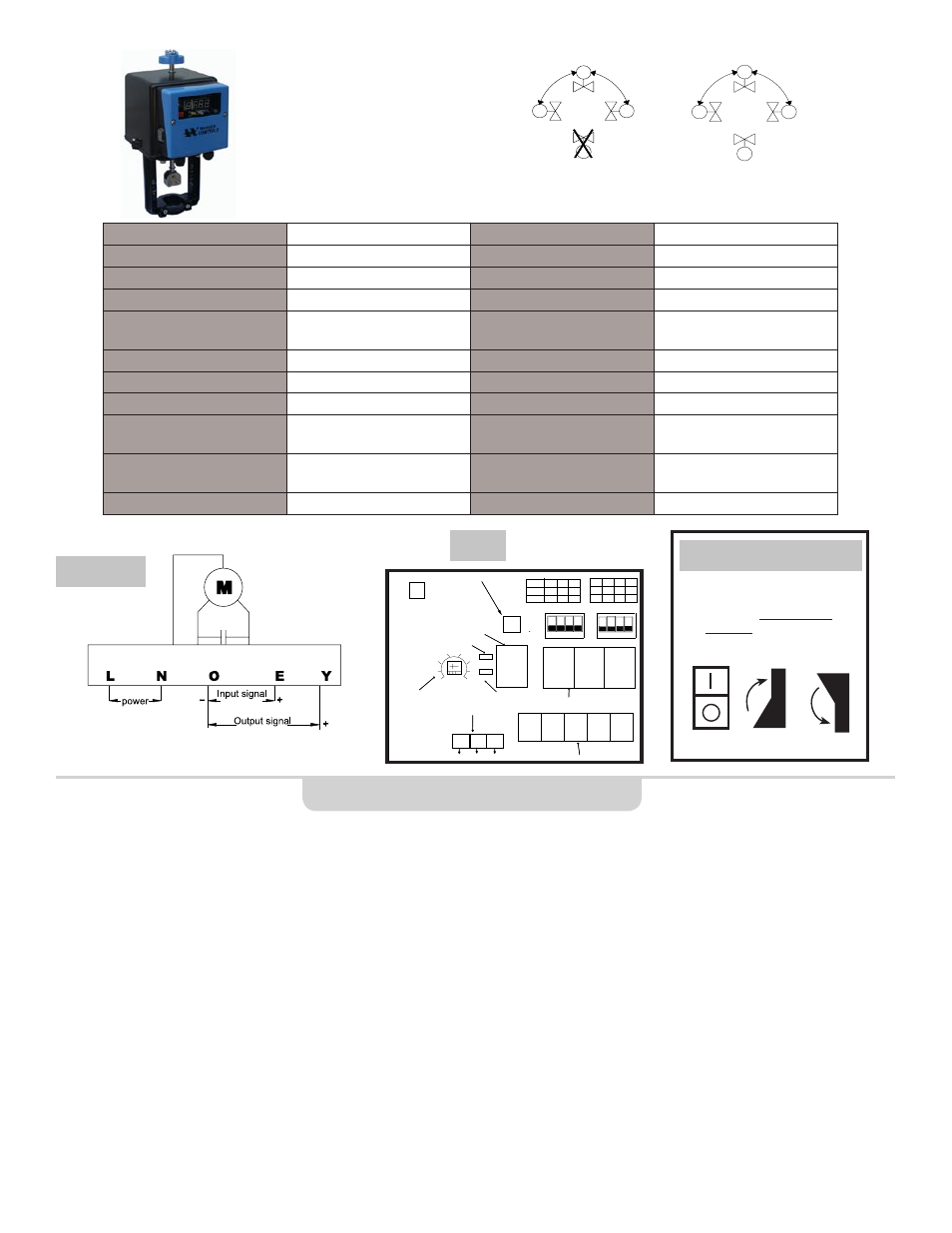

Page 24: Wiring s2 switch setting, Pcb additional function, Debugging m, Eg.1, Eg.2, Err run ul dl al max min err run ul dl al max min, Installation manual device operation

ON-OFF SWITCH

With switch S3-7 OFF (Factory Default), the self-stroking button must be

pressed for self-stroking to start. With switch S3-7 ON, self-stroking starts

each time the actuator is powered up. If switch S3-7 is ON, self-stroking

may also be started by pressing the self-stroking button for greater than

3 seconds. It is recommended that switch S3-7 be OFF.

The self-stroking function must be completed in order to calibrate the

TR5000 actuator to the travel of a valve.

Position the actuator ON-OFF switch in the OFF position. Position switch

S3-7 in the OFF position. Warning: If switch S3-7 is ON, the actuator

will start self-stroking as soon as power is applied. The sudden

movement and application of force may result in damage to the

valve and personal injury. After assembling the TR5000 actuator to the

valve, connect the 220VAC power supply. Position the actuator ON-OFF

switch in the ON position. Then press the self-stroking button on the

PCB and hold (greater than 3 seconds) until the running light flashes

red (1Hz).

– Self-stroking starts

– The actuator stem extends to the lower travel limit; the

running light flashes red (1Hz).

– The actuator stem retracts to the upper travel limit; the

running light flashes red (1Hz).

– The travel limits are recorded in the CPU; self-stroking is

finished (total process takes approx.150 seconds). The

actuator and running light return to normal operation.

1

2

Prepare for assembling actuator, take down the fixed fitting,

and disentangle the clip.

Made the actuator’s stem is concentric with the valve's stem

and made these two connecting faces keep coinciding.

Then lock the two screws on the clip.

3

4

Pulling the fixed fitting to the groove and locking by two screws.

The status after assembled, face and back.

Remark: If the back side have threaded hole, then locking the

other screw on the back. If not, pass over this step.

Installation

Manual device operation

B

o

o

E

Y

B

o

o

E

Y

Take down the front cover, screw off the water

joint, for preparing wiring.

Make the wire through the water joint,

connect the wire to the terminal as required.

Fit on the water joint after wiring.

Install the front cover, screw the screw.

Front cover

through this hole

1

2

3

4

ERR

RUN

UL DL AL MAX MIN

ERR

RUN

UL DL AL MAX MIN

Connecting Sheet

TS-R5000220X12-E01-00

2

Φ

42mm max

Stroke

Mounting Orientation

Dimensions

Chilled/hot water valve body Steam valve body

Forbidded downwards Random Orientation suitable

180°

360°

Power

switch

Knob

Crank

Shut off and prepare for manual operation

Pull out the crank and go round 180 degree

Press down the knob to limit position, keep press

and start to turn the crank.

1. Turn anticlockwise for actuator axes retracts;

2. Turn clockwise for actuator axes extends.

After finished the manual operation, release the knob,

and pull up the knob to the up limit position.

( Any release of press

is not allowed when

the crank running.)

1

2

3

4

TS-R5000220X12-E01-00

8

5

2

3

4

1

ON

OFF

S2

7

8

2

3

4

1

6

5

6

ON

OFF

S2

7

Eg.1

Wiring

S2 Switch setting

warning light

S2 switch

self-stroking button

S2

ERR

RUN

L

O

N

E

Y

ON

1 2 3 4

CPU

OFF

7 8

5 6

LOG

LIN

20%

0

1

2

S2

5 6

7 8

9 10

AL

MAX

MIN

II

UI

IO

UO

1

2

DA

RA

DW

UP

DF

RF

HS

LS

3

4

5

6

S1

running light

nixie tube

connection terminal

additional function terminal

1 2

3 4

UL

DL

--Running light (RUN): when actuator axes retracts, running light show red; when actuator axes extends, running light show green;

when do "self-stroking", running light flickering(1Hz).

---Warning light (ERR): when actuator have some problem, warning light will be lighting.

---Nixie tube: The first one is function bit, the second to forth are numerical bit

Description of Nixie tube:

Function bit

Description

Numerical bit

Description

A

Fault when do "self-stroking"

No show

/

C

Show Input signal on

Numerical bit

Number

between 0~100

Input signal (percent). For example, Input signal type is 0~10V, when input

signal is 1 V, there will be show 1/10*100=10

F

Show Output signal on

Numerical bit

Number

between 0~100

Output signal (percent). For example, Output signal type is 0~10V, when

output signal is 1 V, there will be show 1/10*100=10

When actuator running correctly, there will be show "C" or "F" alternate in the Nixie tube, it is means that "input signal" and "output signal"

be showed alternate.

---Additional function terminal:

1) Terminal 1,2 (UL): Up limit position SPDT output terminal(NO), when actuator axes retracts to limit position, this terminal will be close.

2) Terminal 3,4 (UL): Down limit position SPDT output terminal(NO), when actuator axes extends to limit position, this terminal will be close.

3) Terminal 5,6(UL): Fault SPDT input terminal(NO)when fault, this terminal will be close.

4) Terminal 7,8(MAX): Max. signal compulsory input terminal, this terminal is external connection SPDT, when close, means a Max. input

signal to actuator, and make the input signal from "O","E" terminal be of no effect.

5) Terminal 9,10(MIN): Min. signal compulsory input terminal, this terminal is external connection SPDT, when close, means a Min. input

signal to actuator, and make the input signal from "O","E" terminal be of no effect.

Notes:

1. Contact Capacity of SPDT: :1A (125VAC/30VDC)

2. Contact Capacity external connection SPDT: more than 50mA /30VDC

PCB

Additional function

8

5

2

3

4

1

ON

OFF

S2

7

8

2

3

4

1

6

5

6

ON

OFF

S2

7

S2

Switch

Function

Description

1

Flow character

ON

LOG: equal-percentage

OFF

LIN: equal-linear

2

Starting of input/

output signal

ON

20%:the starting input / output signal is 20% (namely 4~20mA or 2~10V)

OFF

0:the starting input / output signal is 0 (namely 0~20mA or 0~10V)

3

Type of input signal

ON

II: input current signal

OFF

UI: input voltage signal

4

Type of output

signal

ON

IO: Output current signal

OFF

UO: Output voltage signal

5

Operating mode

ON

DA:DA mode (when input signal is increasing, the actuator axes extends )

OFF

RA: RA mode (when input signal is increasing, the actuator axes retracts)

6

Losing input signal

mode

ON

DW: When lose input signal (voltage type), the minimum control signal

When lose input signal (current type), the minimum control signal

OFF

UP: When lose input signal (voltage type), the maximum control signal

When lose input signal (current type), the minimum control signal

7

Output signal mode

ON

DF: when the actuator axes retracts to limit position,output signal will be minimum value

when the actuator axes extends to limit position, output signal will be maximum value

OFF

RF: when the actuator axes extends to limit position, output signal will be minimum value

when the actuator axes retract to limit position, output signal will be maximum value

8

Sensitivity

ON

HS: the high sensitivity of input signal ≤1.5%

OFF

LS: the low sensitivity of input signal ≤2%

Input signal: 0~10VDC

Output signal: 0~10VDC

Operating mode: DA

Losing input signal mode:DW

Sensitivity of input signal ≤2%

Input signal: 4~20mA

Output signal: 4~20mA

Operating mode: DA

Losing input signal mode:DW

Sensitivity of input signal ≤2%

Eg.2

After assemblling TR5000-X...actuator with TL…,TW… or TF... valve body, connect AC 220V power supply. Then press down

"self-stroking" button on PCB over 3 seconds until the running light flickering:

– Self-stroking step starting

– The actuator moving to 1 (actuator axes retracts until up limit position), running light flickering

–The actuator moving to 0 (actuator axes extends until down limit position), running light flickering

– written the result in CPU, self-stoking step is finished ( total process need approx.180 seconds)

Remarks:

1. When in self-stroking, actuator can not be controlled by input singal.

Debugging

M

power

Input signal

Output signal

L N O E Y

Rating force

5000N

Input signal

0(2)~10VDC, 0(4)~20mA

Actual force

4500N~5500N

Output signal

0(2)~10VDC, 0(4)~20mA

Type of control

proportional

Voltage input impedance

>

100K

Power consumption

14VA

Current input impedance

<

0.50K

Motor

Synchronous motor with

permanent magentic

Voltage output load

>

1K

Nominal stroke

42mm

Current output load

<

0.5K

Running speed

2.5s/ mm (50Hz)

Up and down dead band

≤1.5%

Enviromental temperature -10~50℃ (Operation condition) Sensitivity

≤2%

Enviromental humidity

≤95% RH(40℃)

(Operation condition)

Material of bracket

Aluminum die casting

(surface anti-rust process)

IP Degree

IP54

Material of cover

Aluminum die casting

(surface anti-rust process)

Running mode

Up/ down straight travel

Net weight of product

6.0 Kg

1

with manual device

TR5000-X220-S.12

The TR5000 actuator has an

ON-OFF switch.

The switch must be in

the ON position for the

actuator to operate.

ON

OFF

Chilled/hot water application

Not suitable downwards

Steam application

All above suitable

WIRING

PCB

Notes:

1. See separate instruction for installation of TR5000 actuator on PICV valves.

2. When self-stroking, the actuator cannot be controlled by the input signal.

3. The self-stroking function must be repeated each time the type of input signal or output (feedback) signal is changed.

The PCB has an aperture potentiometer. DO NOT adjust the aperture potentiometer. The aperture potentiometer is factory set to 100. If the aperture

potentiometer is adjusted to less than 100, the valve will not function properly as a PICV

S1

self-stroking button

function digit

number digit

ERR

RUN

L

N

O

E

Y

connecting terminal

1 2

3

4

5

6

UL

DL

AL

auxiliary terminal

error light

running light

CPU

maximum

opening

aperture

potentiometer

2

3 4

1

ON

OFF

S2

2 3 4

1

S3

1

2

3

4

20%

0

II

UI

UI

II

IO

UO

5

6

7

8

DA

RA

DW

UP

DF

RF

HS

LS

S2

S3

30

40

50

60

70

80

90

100

220VAC

Rating force

5000N

Input signal

0(2)~10VDC, 0(4)~20MA

Actual force

4500~5500N

Output signal

0(2)~10VDC, 0(4)~20MA

Type of control

proportional

Voltage input impedance

>100K

Power consumption

12VA

Current input impedance

<0.167K

Motor

Synchronous motor with

permanent magnetic

Voltage output load

>1K

Nominal stroke

42mm, 51mm

Current output load

<0.5K

Running speed

3.57s/ mm (50Hz)

Up and down dead band

≤2.5%

Environmental temperature

-10~50ºC (Operation condition)

Sensititivity

low ≤2% high ≤1.5%

Environmental humidity

≤95% RH(40ºC)

(Operation condition)

Material of bracket

Aluminum die casting

(surface anti-rust process)

IP Degree

IP54

Material of cover

Aluminum die casting

(surface anti-rust process)

RUNNING MODE

Up/down straight travel

Net weight of product

5.2 Kg

DEBUGGING/SELF-STROKING

TR5000-X220S.12 / TR5000-X220-S.12-51