KROHNE BM 100A Handbook User Manual

Page 14

14

Handbook BM 100 A

1.3.4 Specific

installation

instructions: gauge - liquid applications

Probe bending in agitated products: recommended solutions

Probe (Type)

Supports and fastenings

Stilling well installation*

Twin rod (A)

Weld a 45mm / 1.8” internal diameter tube on

the bottom of the vessel then insert the

probe.

Possible. On-site calibration may

be required to maintain accuracy.

Repeatability is unaffected.

Twin cable (L)

Fit an anchor with an M10 x 1 (Ø4mm/0.16”

cable) thread (i.e. spring ring or hook) to the

counterweight*** CAUTION: 6 Nm / 4.4 lbf.ft

maximum torque. This cable may also be

ordered with a turnbuckle.

Possible. On-site calibration may

be required to maintain accuracy.

Repeatability is unaffected.

Centring the probe is

recommended. Contact KROHNE

for more information.

Single rod (F)

Weld a 12mm / 0.5” internal diameter tube on

the bottom of the vessel, insert the rod****.

Possible. 50 mm / 2” minimum

diameter chamber. Contact

KROHNE for assistance.

Single cable (H) Fit an anchor with M10x1 (Ø4mm cable)

thread underneath the counterweight : spring

ring or hook. CAUTION: 4 Nm / 2.9 lbf.ft

maximum torque. This cable may also be

ordered with either a chuck or turnbuckle.

Possible. 50 mm / 2” diameter

minimum. Contact KROHNE for

assistance**.

Coaxial (D)

Weld a 30-32mm / 1.2” internal diameter tube

on the bottom of the vessel, insert the tube. A

probe may be fixed with braces.

Unnecessary: probe unaffected

by nearby objects.

* Reference (bypass) chamber or stilling well.

**

Spacers supplied by KROHNE.

*** Threaded hole provided in base of counterweight.

**** Contact KROHNE. A factory menu function may need to be changed.

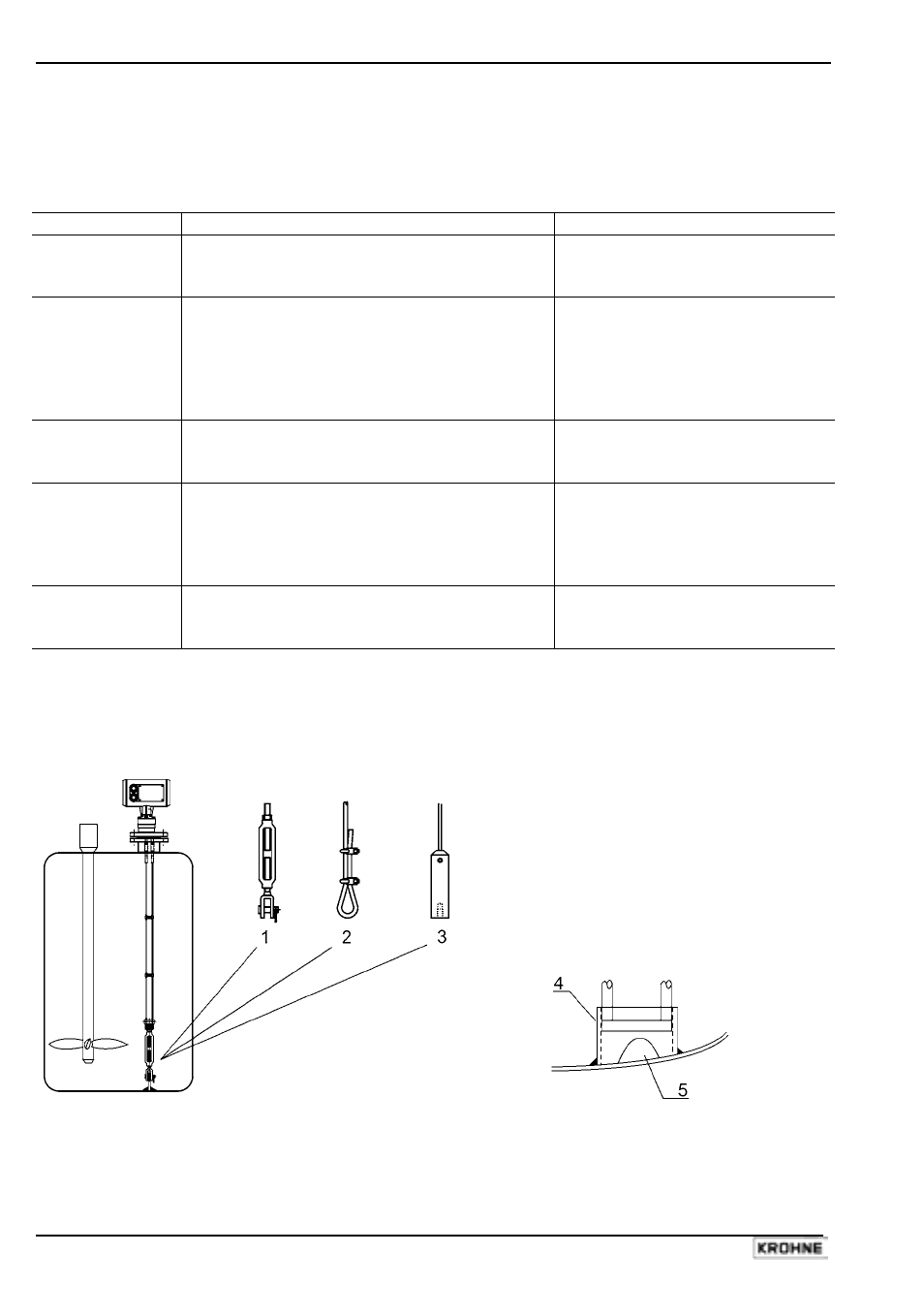

1 Turnbuckle

2

Chuck for type H Ø4mm

single cable probe

3

Counterweight with threaded base

4

Avoid play between tube and probe

5

Hole in welded tube for drainage

Anchoring twin rod and coaxial probes