Service, 2 cleaning – KROHNE OPTISENS PAS 2000 EN User Manual

Page 28

6

SERVICE

28

OPTISENS PAS 2000

www.krohne.com

11/2008 • MA PAS 2000 R04 en

6.1.3 Incorrect measurements

6.1.4 Cleaning of the flushing nozzle

If the flushing nozzle becomes plugged, it can usually be cleaned by back flushing it with clean

water. Before attempting to backflush, close the valve for the flush water source and disconnect

the sensor flushing hose from the solenoid valve. Then, place a 12 mm hose over the flush

nozzle and carefully open the water valve.

The pressure should clear the line of solids. If backflushing does not work initially, try cleaning

the flushing nozzle with a needle. Try backflushing the nozzle again as described above until

clean water comes out at the solenoid valve end of the hose.

6.2 Cleaning

The sensor is equipped with a flushing nozzle. The nozzle is used to direct the cleaning liquid

supplied through a 6 mm hose that is mounted along the sensor housing to flush the electrode. A

solenoid valve that is wired to a relay in the MAC 080 converter controls the air or liquid (see

handbook OPTISENS MAC 080).

Compressed air is recommended for most applications.

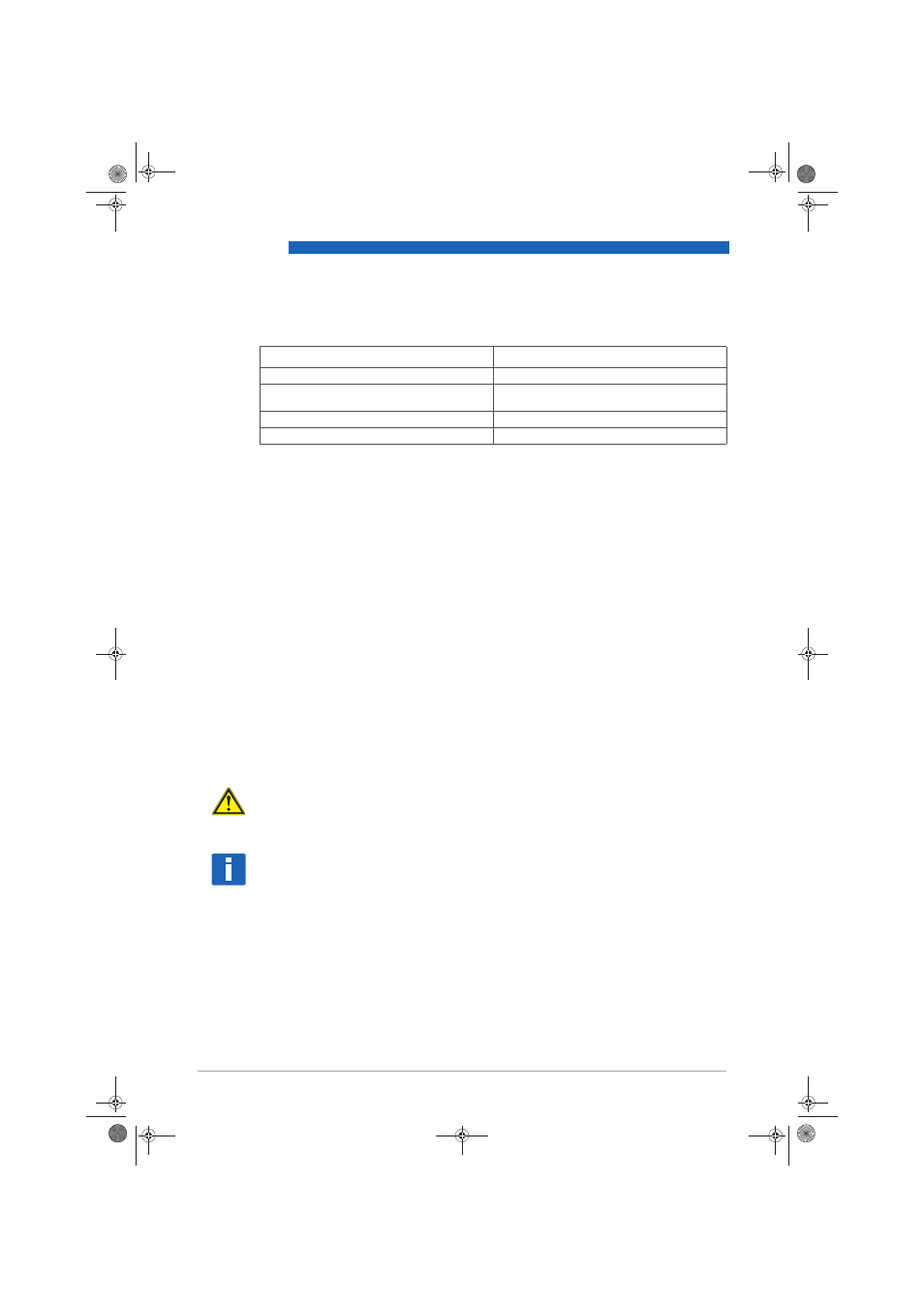

Problem

Solution

Dirty electrode

Clean with distilled water

Insufficient or poor reference solution in the

electrode

Refill/change reference solution (only for refillable

electrodes)

Change of "slope" due to age

Recalibration

Old electrode which gives slope <93 %

Change electrode

CAUTION!

For PAS 2000 submersible sensor the highest allowed flushing pressure is 6 bar / 87 psi. When

using air, 2 bar / 29 psi is usually sufficient.

NOTE!

Pay attention to the requirements for protection against backflow, according to the

EN 1717 standard for drinking water devices. If possible, use plant reuse water or effluent water

for cleaning.

.book Page 28 Friday, November 28, 2008 2:32 PM