Service, Service 6.1 maintenance – KROHNE OPTISENS PAS 2000 EN User Manual

Page 27

SERVICE

6

27

OPTISENS PAS 2000

www.krohne.com

11/2008 • MA PAS 2000 R04 en

Service

6.1 Maintenance

PAS 2000 sensors are easy to maintain. An electrode maintenance schedule should be kept,

listing when it is removed and cleaned. When this is done, the electrode should be checked

against a known buffer solution. If the control value does not match, a re-calibration should be

made.

Regularly check that the sensor does not get damp or wet inside during cleaning and other

activities. Also check that the electrode is correctly mounted in its holder to avoid leaking.

6.1.1 Broken electrode

Lightning or static discharges during thunder storms may cause damage to the electrode, and

could also damage the signal amplifier. The electrode is the most exposed point since it is in

direct contact with the water and, consequently, the ground connection for a discharge.

Physical damage to the electrode usually makes measuring impossible. Make sure that neither

electrode nor cable is damaged.

6.1.2 Error messages

CAUTION!

Use distilled water for cleaning, otherwise the calibration and in worst case the total life time of

the electrode might be compromised.

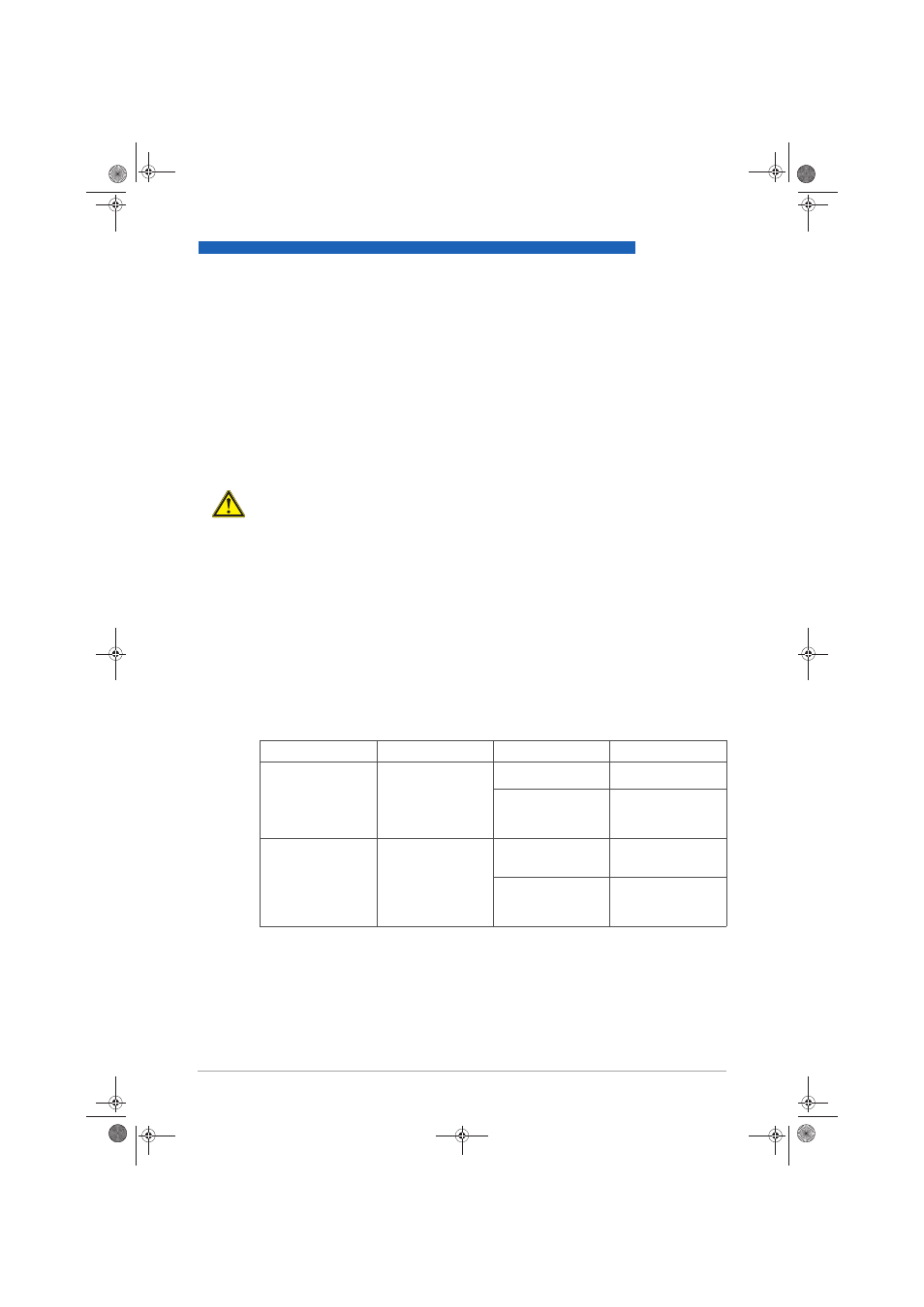

Display text

Explanation

Cause

Solution

Unkown buffer

The smart calibration

does not recognize the

current buffer from the

signal of the electrode.

Unknown buffers have

been used.

Use standard buffers

4.00, 7.00 and 10.00.

Broken sensor,

damaged electronic

components or bad

cable connection.

Check or reseat cable

connection. Inspect

electrode and exchange

it if damaged.

Same buffer

During calibration the

PAS 2000 pH does not

perceive a difference of

buffers.

Same buffers have been

used.

Make sure that you use

two different buffers

during calibration.

The electrode or the

electronic components

in the sensor may be

broken.

Inspect electrode and

exchange it if damaged.

.book Page 27 Friday, November 28, 2008 2:32 PM