Operation, 3 troubleshooting – KROHNE PipePatro EN User Manual

Page 42

3

OPERATION

42

PIPEPATROL

www.krohne.com

02/2013 - 4002275001 - MA PipePatrol R01 en

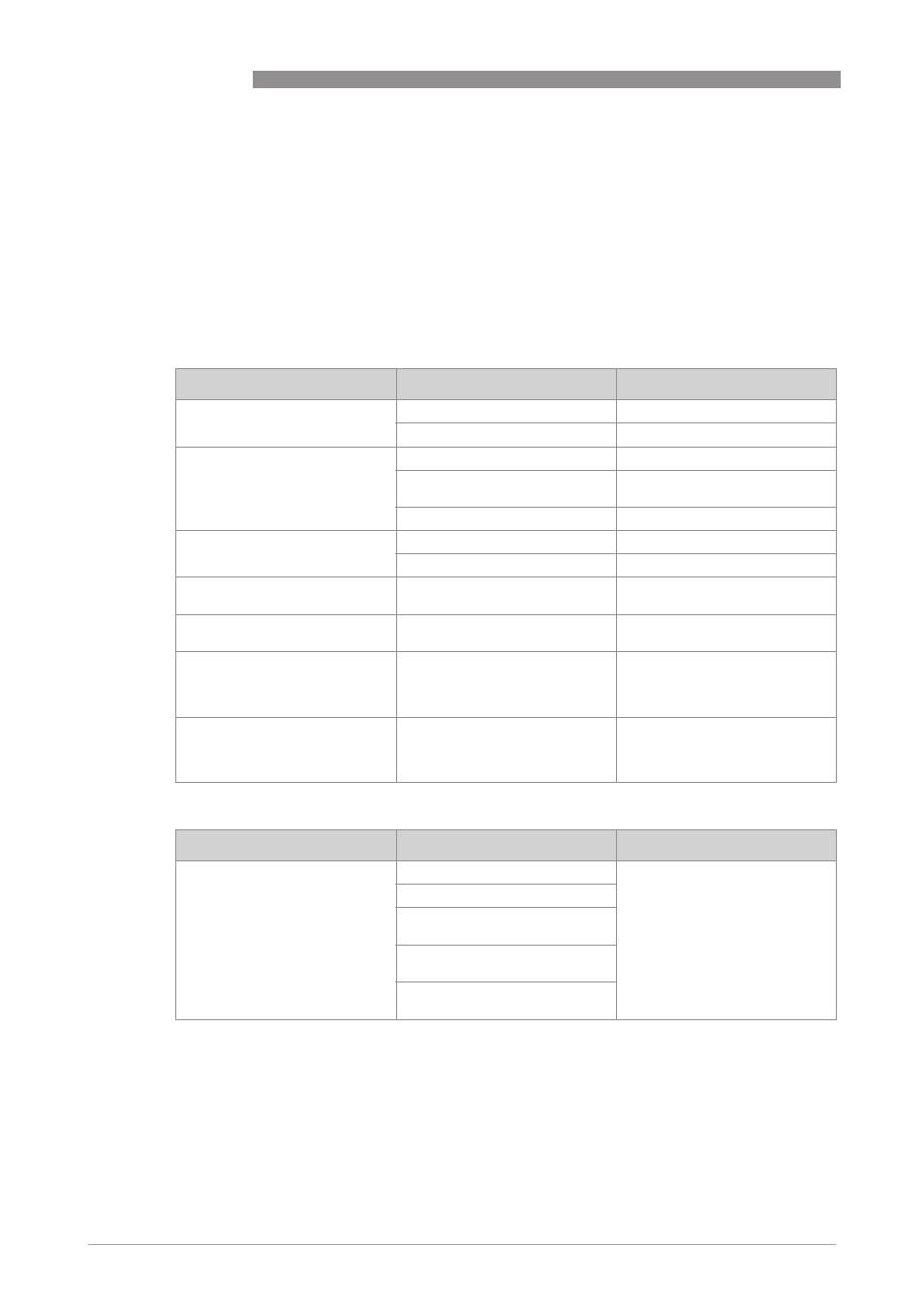

3.7.3 Troubleshooting

For troubleshooting it is necessary that the maintenance crew has a profound knowledge of the

leak detection system.

Possible errors can be divided in internal and external. Internal errors are declared as occurring

in the leak detection software program, e.g. an incorrect parameter setting. External errors are

failures outside the LDS operator or monitoring station, e.g. a failure in the data communication

system.

Internal error

External error

Error

Cause

Action

The status window of the OS

indicates a system error

Wrong parameter setting

Correct parameter.

Internal error

Contact manufacturer.

No reaction when PC is switched

on

No power available

Check electrical connection.

Power supply failure

Check the power supply of each

LDS station.

Other reason

Contact manufacturer.

The PC does not boot

Disk or CD in drive

Take out disk and press any key.

Other reason

Contact manufacturer.

PC starts-up, software loads but

LDS is not operational

Error in software/hardware or

outside the PipePatrol software.

Contact manufacturer.

PC does not boot and internal

speaker gives signal

Component in PC broken

Contact manufacturer.

The data states on the user HMI

reports periodically data errors

Runtime problems caused by the

installed operating system

Restart the monitoring station.

If the system is reporting the

error again contact the

manufacturer.

The "Status Window" of the user

HMI indicates ERROR OPC-

Connection

Connection to the LDS OPC-

Server fails

Restart the monitoring station.

If the system is reporting the

error again contact the

manufacturer.

Error

Cause

Action

The "Status Window" of the OS

indicates that the LDS is not

working or "Data State" indicates

data error/warning while the

pipeline is in normal use

A measurement sensor is broken Check status of datacom

Data communication is lost

Some transmitted signals are out

of the predefined range

No signal received from valve

position change

No signal received from batch

change