Operation, 1 status window – KROHNE PipePatro EN User Manual

Page 14

3

OPERATION

14

PIPEPATROL

www.krohne.com

02/2013 - 4002275001 - MA PipePatrol R01 en

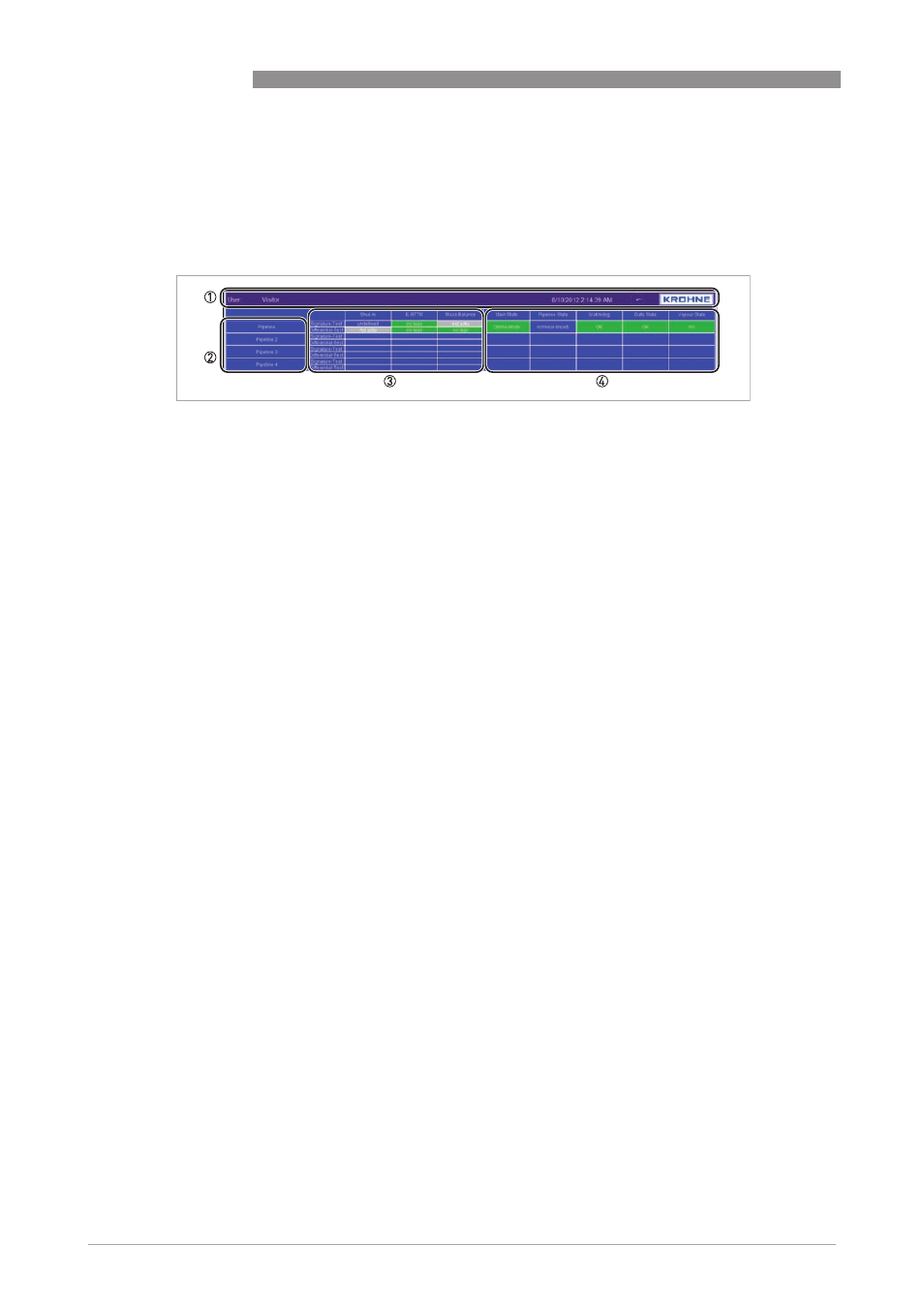

3.3.1 Status window

The status window shows main information of each applicable system, which is available on each

screen of the PipePatrol HMI. The functionality of each information is explained in the following

part.

1

General error information from the operator station

General error information from the operator station

General error information from the operator station

General error information from the operator station

The operator station is the PC where the actual HMI is running.

The following information can be shown:

•

Name of the user who is logged in

•

Date and time of the operator station machine

•

Error OPC Connection (red/flashing)

The connection to the OPC server of the leak detection software is lost.

2

Name of the leak detection system

Name of the leak detection system

Name of the leak detection system

Name of the leak detection system

The operator station HMI is designed to be able to monitor several running leak detection systems

which are designated by a unique system name. A click on one of the systems, switches the operator

screen to the leak information of the selected leak detection system.

3

Alarm information of the running leak detection

Alarm information of the running leak detection

Alarm information of the running leak detection

Alarm information of the running leak detection

The system performs leak detection by using different modules. Each module provides alarm

information by Signature-Test and Differential-Test. The usage of these modules depends on the

actual running conditions of the pipeline.

•

Shut-In:

Shut-In:

Shut-In:

Shut-In: This module is performing an analysis of the pressure reading inside the closed pipe

section. As long one of the reading is available it will perform leak detection for standstill

conditions.

•

E-RTTM:

E-RTTM:

E-RTTM:

E-RTTM: This module indicates the model based leak detection. It will be activated as long flow,

pressure and temperature readings are available.

•

Mass Balance:

Mass Balance:

Mass Balance:

Mass Balance: This module offers a statistical analysis of the inlet and outlet flow. As long both

readings are available it will provide leak detection in pumping conditions.

•

Following additional modules, following the same operating philosophy, may be available:

- Virtual Flow

- Substation Monitoring

The following information can be shown:

•

Undefined (blue):

Undefined (blue):

Undefined (blue):

Undefined (blue): LDS is not running; no leak information is available.

•

Unknown (blue):

Unknown (blue):

Unknown (blue):

Unknown (blue): LDS is starting-up; leak information will be available soon.

•

No leak (green):

No leak (green):

No leak (green):

No leak (green): The system is running; no leak is detected.

•

Leak Alarm (red flushing):

Leak Alarm (red flushing):

Leak Alarm (red flushing):

Leak Alarm (red flushing): The system is up and running and a leak has been detected.

•

Acknowledge alarm (blue):

Acknowledge alarm (blue):

Acknowledge alarm (blue):

Acknowledge alarm (blue): An alarm has been detected and confirmed by a logged operator.

4

States information of the running leak detection

States information of the running leak detection

States information of the running leak detection

States information of the running leak detection

The following state information are available:

•

Main State:

Main State:

Main State:

Main State: Indication of the main systems states.

•

Pipeline State:

Pipeline State:

Pipeline State:

Pipeline State: Indication of the actual pipeline conditions.

•

Watchdog:

Watchdog:

Watchdog:

Watchdog: Indication of the actual status of the watchdog monitoring.

•

Data State:

Data State:

Data State:

Data State: Indication of the actual status of data gathering.

•

Indication of the status of vapour monitoring along the line.

For detailed information refer to the following details.