Technical data, 2 technical data – KROHNE OPTITEMP TT 51 EN User Manual

Page 40

7

TECHNICAL DATA

40

TT 51 SERIES

www.krohne.com

09/2010 - 4000754201 - MA TT 51 R01 en

7.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

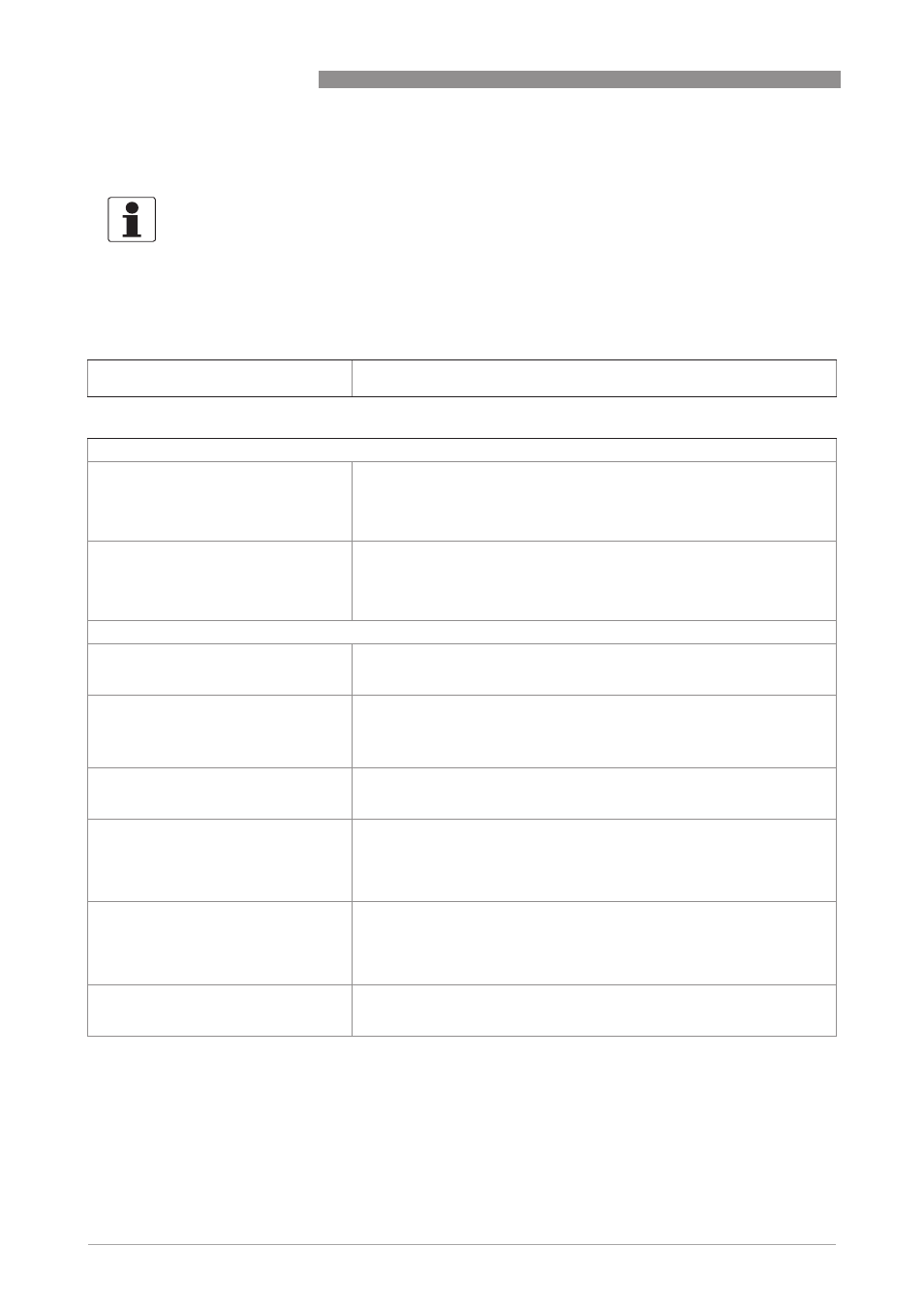

Measuring system

Application range

Temperature, resistance or voltage measurements of solids, liquids and

gases in industrial environment.

Design

Versions

Versions

Versions

Versions

TT 51 C

In-head transmitters which are intended for installation in a "B connection

head" or larger according to DIN 43729.

This transmitter is optionally available in a non-incendive version (zone 2)

and in an intrinsically safe version (zone 0, 1 and 2) for installation in

potentially explosive atmospheres.

TT 51 R

Rail-mount transmitters which are intended for installation on a rail

according to DIN 50022 / EN 60715.

This transmitter is optionally available in a non-incendive version (zone 2)

and in an intrinsically safe version (zone 1 and 2) for installation in

potentially explosive atmospheres.

Features

Features

Features

Features

SIL 2 compliance

Based on a hardware assessment acc. to IEC 61508-2, consisting of a

FMEDA done by exida, the transmitters are suitable for use in SIL 2 rated

Safety Instrumented Systems (SIS).

HART

®

6 compliance

The transmitters are fully compliant with the HART

®

6 protocol as well as

the previous HART

®

5. HART

®

6 offers the possibility to receive diagnostic

information such as sensor errors or sensor conditions, input wiring

resistance too high, sensor backup mode, transmitter error, etc.

Sensor backup

Dual-sensor input allows for backup between two sensors. Should a lead

break or short-circuit be detected on one of the sensor circuits, an

automatic switchover to the intact sensor will occur.

Sensor drift monitoring

If an RTD or thermocouple with double sensor elements is used, sensor drift

can be detected by checking the reading from both elements. If the

difference is above a user-defined level, this will be indicated in ConSoft and

with a diagnostic HART

®

message, and the output signal can be forced

upscale or downscale.

Sensor isolation monitoring

The isolation resistance of thermocouples and RTD’s as well as the cabling

between sensor and transmitter is being monitored. If the isolation is below

a user-defined level, this will be indicated in ConSoft and with a diagnostic

HART

®

message, and the output signal can be forced upscale or downscale.

This feature requires an extra lead inside the thermocouple or RTD.

Customized linearization

For resistance and mV inputs, the 50-point customized linearization can

provide a correct process value, in a choice of engineering units, for a sensor

with non-linear input/output relation.