0 trouble-shooting, 1 sensor faults, 2 troubleshooting rs485 networks – Detcon 1640-N4X User Manual

Page 22: Trouble-shooting, Sensor faults, Troubleshooting rs485 networks

1640-N4X

1640-N4X Instruction Manual

Rev. 0.0

Page 18 of 28

6.0 Trouble-shooting

6.1 Sensor Faults

The unit is set up such that Sensor faults will set Fault alarms associated with that sensor. If a sensor goes into

a fault condition, that channel will flag a fault. From the “Main Screen” each channel can be quickly viewed

to see which channel is causing the fault. That sensor should be then checked to find the cause of the fault.

Faults are logged in the Alarm History for aid in tracing intermittent sensor problems. Refer to the appropriate

sensor manual for more information on trouble-shooting sensor faults.

6.2 Troubleshooting RS485 Networks

The first step in finding the bad device or several bad devices is to start at the master:

1. Disconnect the data cable bus wires going to all of the slave devices from the output terminal blocks

(A and B).

2. Connect a known working slave device directly to the master (attached directly to the output terminal

blocks) and make sure that it is functional. If it is not, replace the 1640 Controller PCA.

3. Disconnect the working device connected in Step 2, and re-connect the data cable bus wires (A&B) to

the master.

4. Use a voltmeter to measure the voltage across the A and B wires and write the reading down. This

reading should be 400-500mV.

5. Go to the first slave device. Re-connect or plug the device in and measure the voltage across A and B.

Write down the reading. The measurement taken should be 400 to 500mV. If the voltage is not

within the specified range, verify that all devices have been unplugged from the data bus.

6. Unplug the first device and proceed to the next slave device. Record the meter readings. Again the

reading should be 400-500mV. If the reading is not 400-500mV a wiring problem may exist, or the

transmitter may be non-operational.

7. Repeat the procedure with each slave device, recording the readings along the way. If any of the other

readings taken are above or below the first reading by more than 50mV that unit’s transmitter or the

module should be replaced.

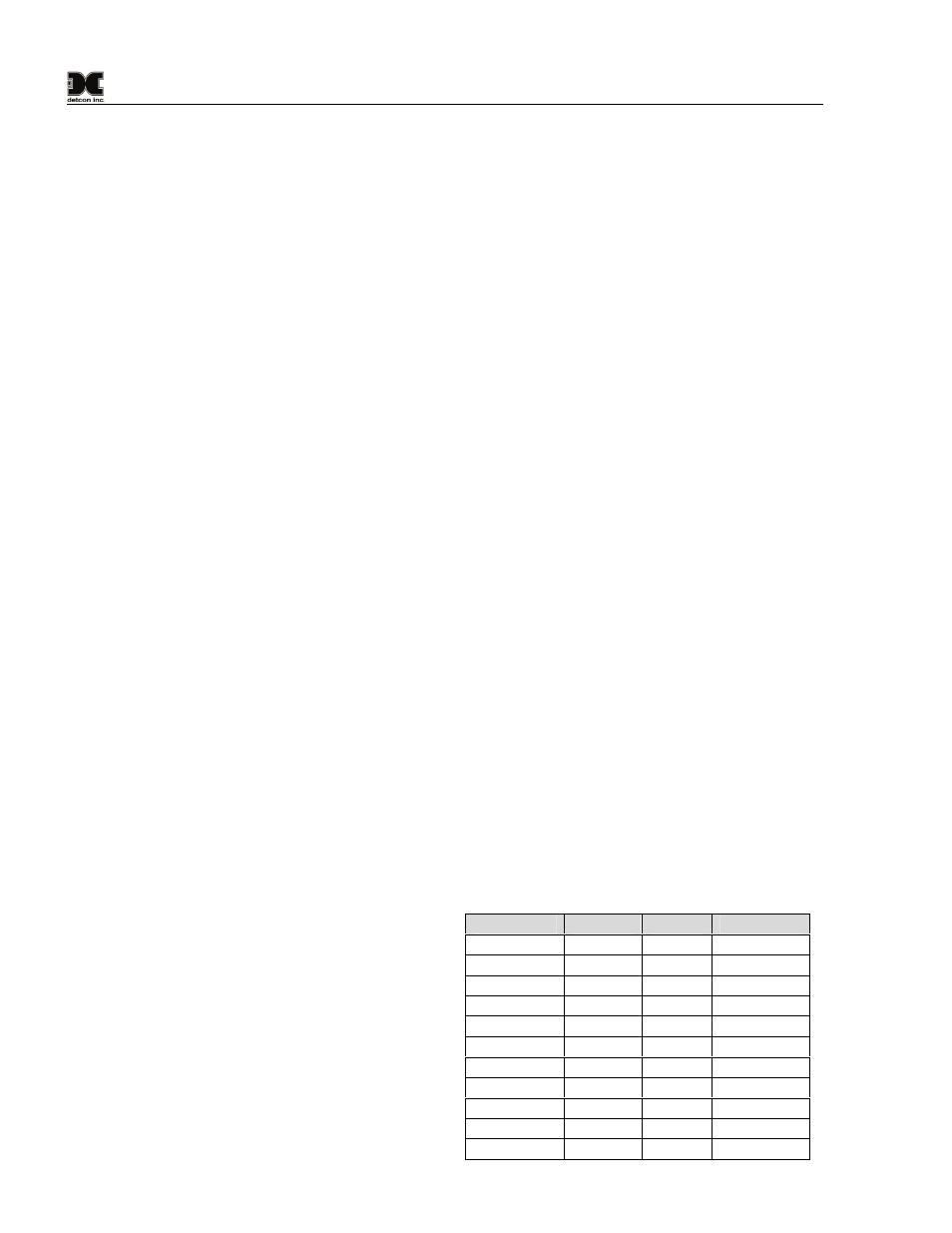

Slave

Master

MV

Difference

ID 01

425

451

26

ID 02

425

430

5

ID 03

425

486

61

ID 04

425

410

-15

ID 05

425

420

-5

ID 06

425

432

7

ID 07

425

422

-3

ID 08

425

415

10

ID 09

425

418

-7

ID 0A

425

440

15

ID 0B

425

310

115

Results similar to those

shown here should be

expected. In this example

slave device 03 and 0B

would need to be changed.