Star Water Systems Star 4in Sub Instr2&3-wire User Manual

Page 4

6

Copyright © 2014 Star Water Systems. All rights reserved.

7

Copyright © 2014 Star Water Systems. All rights reserved.

ASSEMBLY INSTRUCTRIONS

ELECTRICAL HOOkUP AT THE PUMP

Torque

Arrestor

Approx. 4 ft.

3

3. Firmly clamp the torque arrestor to the pipe

approximately 2 to 4 ft. above the pump,

using the two clamps provided with the torque

arrestor.

(Fig. 3)

4. Typical installations include the following

components. Purchase these items separately

depending on your need.

(Fig. 4)

Discharge pipe - delivers water to home

Well seal or pitless adapter - keeps debris out of

well

Safety rope - prevents pump from falling

Check valve - keeps water in pipe

Electrical cable - connects to house electricity

Torque arrestor - keeps pump stable

Drop pipe - connects pump to discharge

Well casing - holds all components

Discharge Pipe

Spring-Loaded Check Valve

(Recommended every 100 ft.)

Safety Rope

Well Seal or Pitless Adapter

Well Casing

Torque Arrestor

Drop Pipe

Electrical Cable (Secured to drop

pipe with tape or clamps every

10 ft.)

Pump

4

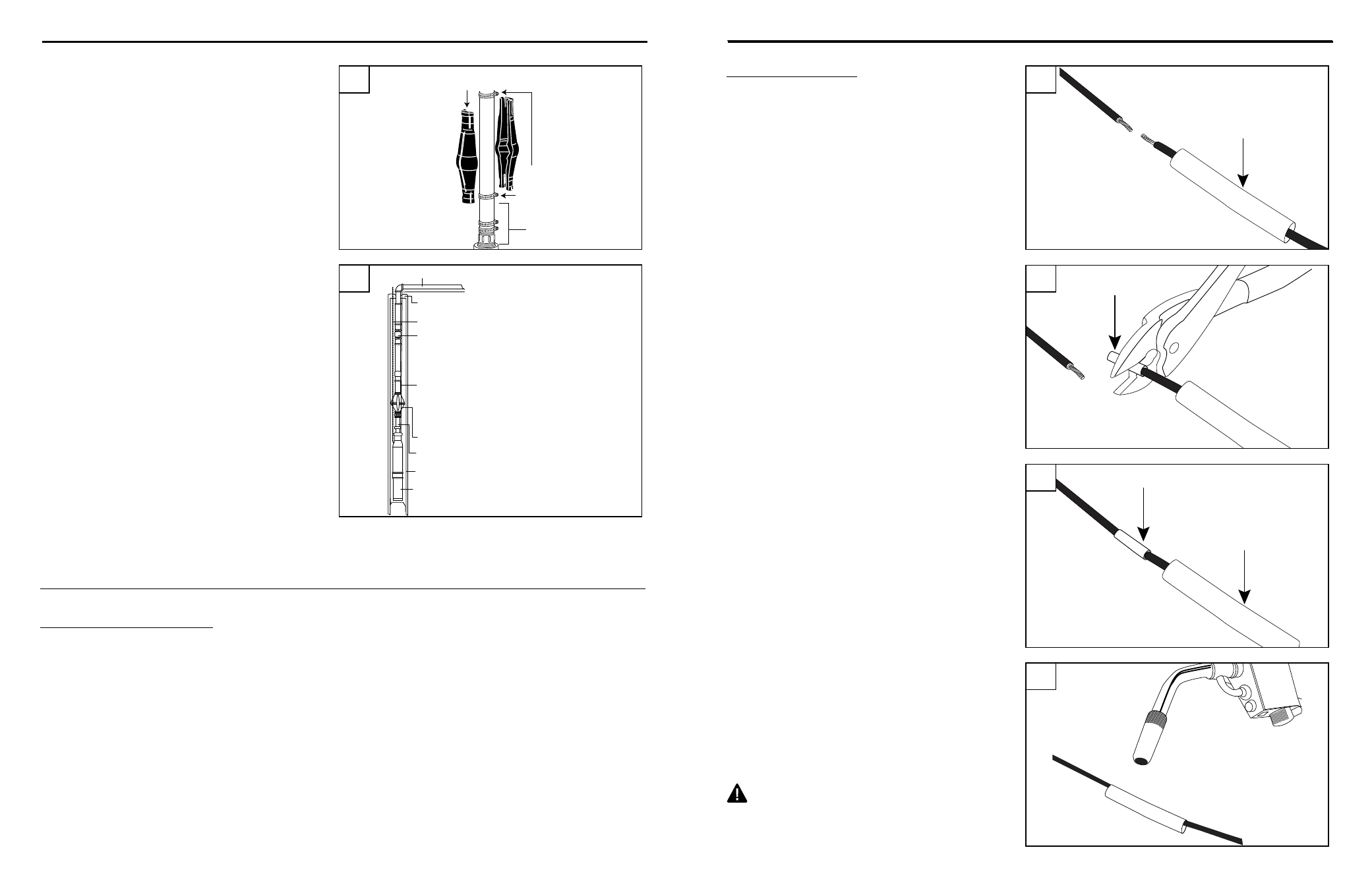

Submersible Cable Splicing

Pump is equipped with a lead wire assembly. The length of wire needed to attach to this lead wire assembly is

equal to the distance from the pump in the well to the top of the well. Additional wire will be needed to run

from the top of the well to the house.

CAUTION: Follow instructions carefully to make a watertight splice. A leak in the splice can result in pump

damage, blown fuses, overload protector tripping or electric shock hazard.

ELECTRICAL HOOkUP AT THE PUMP

Shrink tube

Metal Connector

2

Splicing instructions

1. Slide one black shrink tube from a heat shrink

splice kit over each wire (including the green

ground wire) coming out of the pump.

(Fig 1)

2.

NOTE: For each wire coming out of the pump

, including the green ground wire, slide the

wire from the pump into one end of a metal

connector from the splicing kit. Then slide

stripped end of wire from electrical cable into

other end of metal connector. Connector should

be centered over both wires. Squeeze metal

connector until it closes tightly over both wire

ends.

(Fig 2)

IL1145

Shrink tube

Metal Connector

ON

OFF

IL1146

3

4

3. Slide one shrink tube over each crimped joint.

(Fig 3)

4. Hold a torch approximately 6 in. from the center

of the tubing and move it back and forth. Heat

one set of wiring tubing at a time until seal is

completed. During the heating process, keep all

other wires/tubing away from heat to prevent

melting together. Avoid overheating, as this may

make the tubing brittle. When liquid oozes from

end of tube, seal should be complete.

(Fig 4)

CAUTION: Do not lift pump by power cable

or motor leads! Damage to cable or leads will

result.

1