4 maintenance schedule – Seed Hawk TOOLBAR 2015 User Manual

Page 53

SEED HAWK

®

2015 TOOLBAR OPERATOR’S MANUAL

48

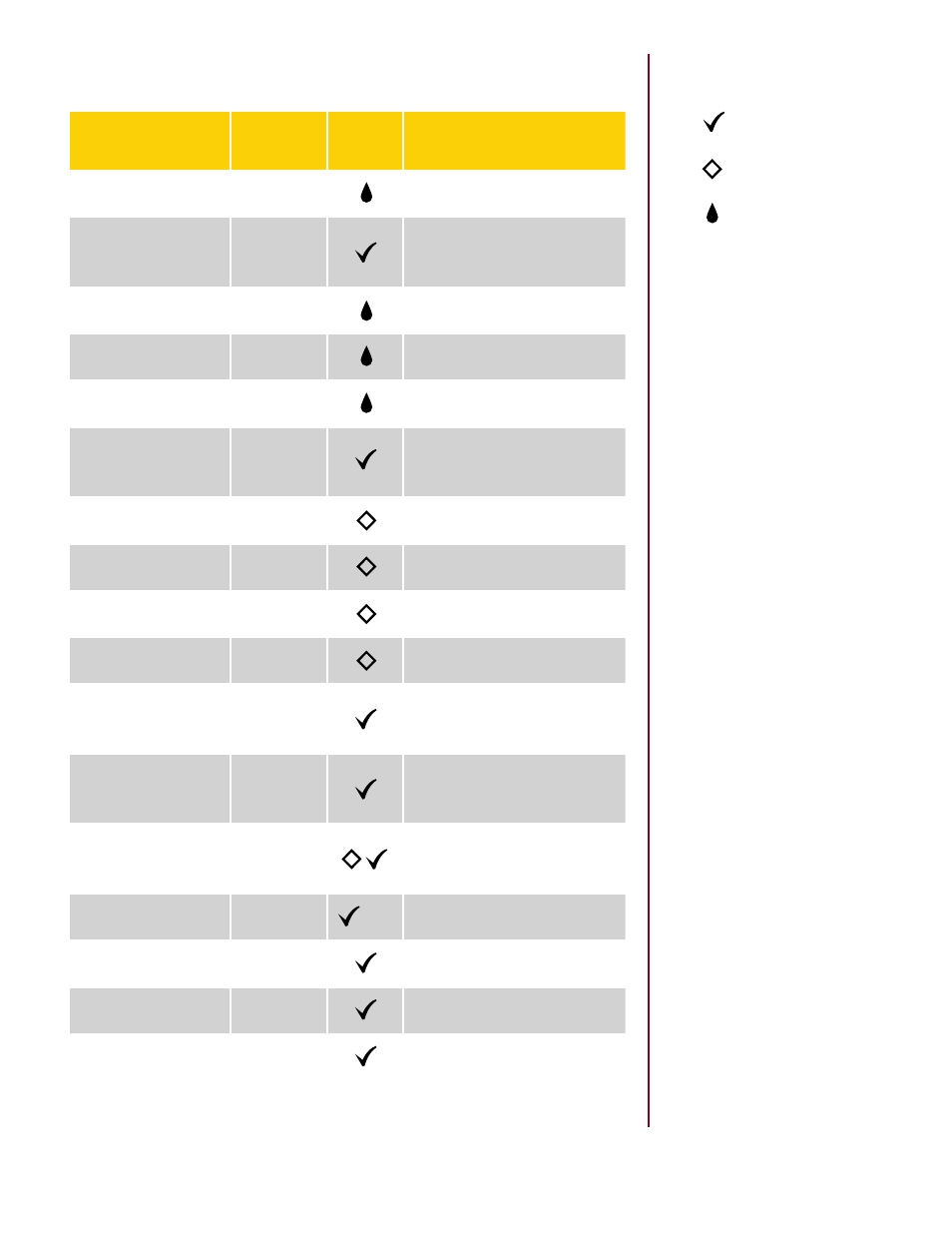

Item

Frequency

(hours)

Service

Notes

Castor Wheel Plate

grease fittings

12

Daily

2 fittings: 1-top, 1-bottom

Castor Wheel

Plate gap

100

1/8” (3mm) max

tighten castor bolt if max

exceeded

Wheel Hubs

main frame

100

100 hrs or annually re-pack

bearings or 2 pumps grease

Wheel Hubs wing

100

100 hrs or annually

Wheel Hubs

packer wheel

100

100 hrs or annually

Seed/Fertilizer

Knives & related

components

10/100

10 hrs or inspect daily, and,

100 hrs or before seeding

Liquid Fertilizer (opt)

main filter screens

100

100 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

basket filter(s)

50

50 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

system flush

100

100 hrs or before seeding, or

between chemical changes

Liquid Fertilizer (opt)

nozzle bodies

100

100 hrs or before seeding, or

between chemical changes

Wings down

(if configured)

100

At end of seeding season, or

when stored for long periods

of time

Ball lock valves open

100

At end of seeding season, or

when stored for long periods

of time

Dump Line

open drain in pail

100

At end of seeding season, or

when stored for long periods

of time

Hydraulic Cylinders

cylinder seals

10 /

A/R

10 hrs or daily; inspect &

replace as required (A/R)

Check all machine

fasteners

100

At the beginning of every

seeding season.

Tires

air pressure

10

10 hrs or daily; inflate to

proper pressure

Opener Pivot Points

100

Annually re-torque

6.4 Maintenance Schedule

A/R

Replace as

Required

A/R

Check

Clean

Lube