1 slope adjustment, 2 temperature errors cause by non-graybodies – LumaSense Technologies ISR 6 Advanced User Manual

Page 22

ISR 6 Advanced Manual

Settings / parameter descriptions · 22

using a thermocouple probe or by knowing one process temperature point precisely from other

sources. The K-factor can then be adjusted until the pyrometer shows the same temperature

value.

The ISR 6 is factory calibrated for graybody targets that exhibit equal changes in emissivity

within its two spectral bands.

Note: Emissivity Slope K Settings: 0.800 to 1.200 in steps of 1/1000 (2-color mode).

4.3.1 Slope Adjustment

In some cases the emissivities of the two wavelengths can differ so that it is necessary to correct

the ratio of the two emissivities (K = e1 / e2) to get a correct temperature reading. This

correction can be done by adjusting the emissivity slope setting K using the InfraWin software or

the UPP data format commands.

The K-factors of metals are normally slightly higher than 1. For a correct measuring result, it is

recommended that you make a comparison test. This comparison test may be performed by

using a thermocouple probe or by knowing one process temperature point precisely from other

sources. The K-factor can then be adjusted until the pyrometer shows the same temperature

value.

The ISR 6 Advanced is factory calibrated for graybody targets that exhibit equal changes in

emissivity within its two spectral bands.

4.3.2 Temperature Errors Cause by Non-Graybodies

A graybody target has emissivity that is the same at each of the two wavelengths used for

measurements and is constant throughout the temperature range. The ratio of the emissivities,

e1 / e2= 1 and stays constant regardless of the target temperature. When a target deviates from

this, that is when e1 / e2 does not equal 1.0 and a slope adjustment is required. For many

materials, this is a one-time adjustment.

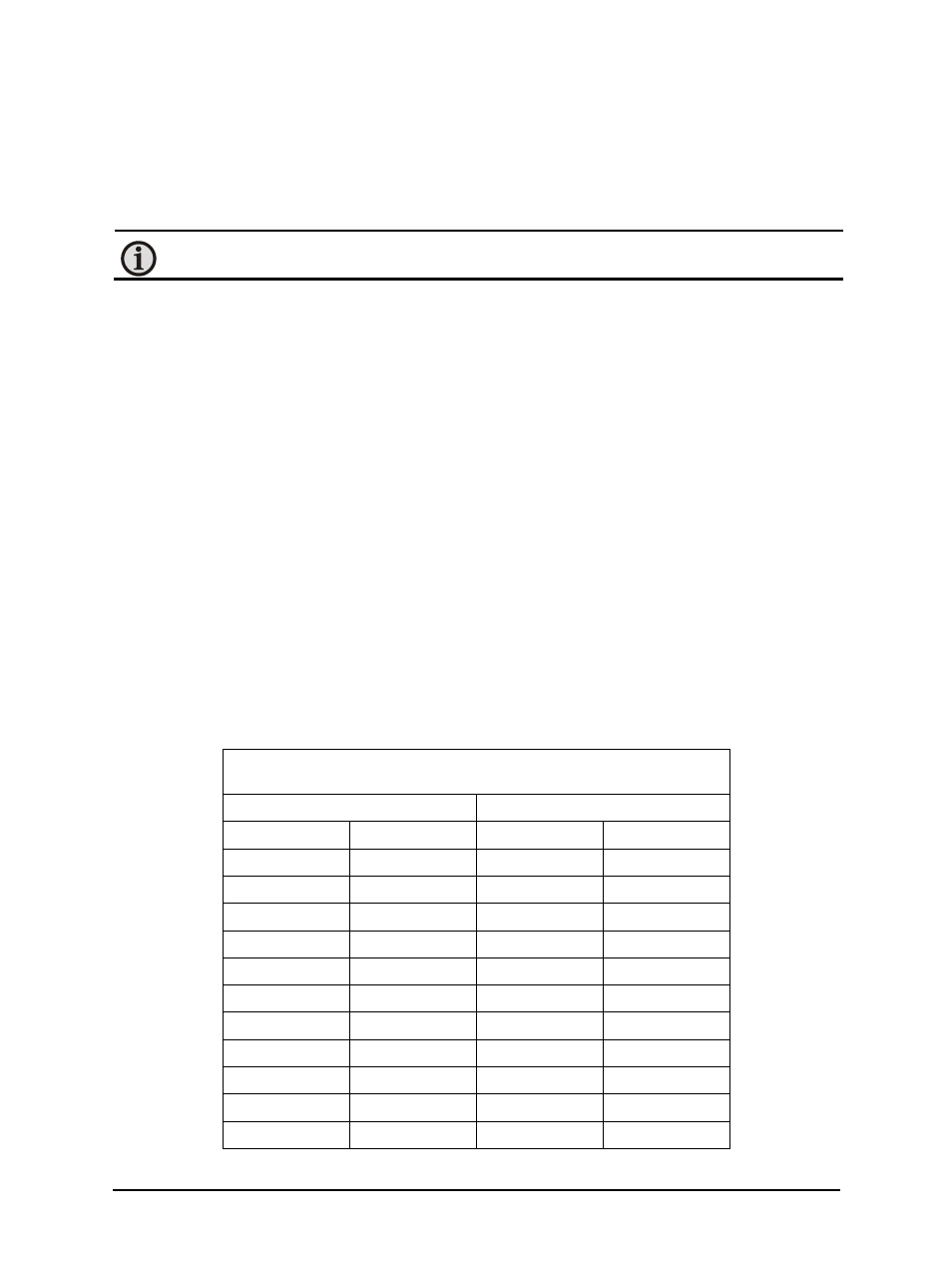

The following table illustrates the ISR 6 reading errors that can occur when the slope setting

differs from the actual material emissivity ratio.

TABLE OF EXPECTED ERROR WHEN EMISSIVITY OF ONE

WAVELENGTH IS 1% DIFFERENT FROM THE SECOND WAVELENGTH

TEMPERATURE

ERROR DEG.

°F

°C

°F

°C

1300

700

18

10

1500

815

20

11

1700

926

22

12

1900

1040

25

14

2100

1150

25

14

2300

1260

27

15

2500

1370

29

16

3000

1650

36

20

3500

1925

45

25

4000

2200

54

30

5000

2760

72

40