Pump connections (general) – Stuart Turner 3.2 bar PS User Manual

Page 7

- 7 -

4. Push pipe firmly into fitting, until pencil mark is level with the top of the collet and the

pipe stop resistance is felt. Pull on pipe to check it is secure and correctly fitted.

5. To release the joint, push pipe firmly into fitting, hold the collet down and gently

remove pipe. If the system has been filled with water care should be taken to isolate

pump and towels used to absorb spilled water.

If you have any concern either about using push-in fittings or should the joint leak on final

test, isolate the water supplies and contact Pump Assist on 0844 98 000 97.

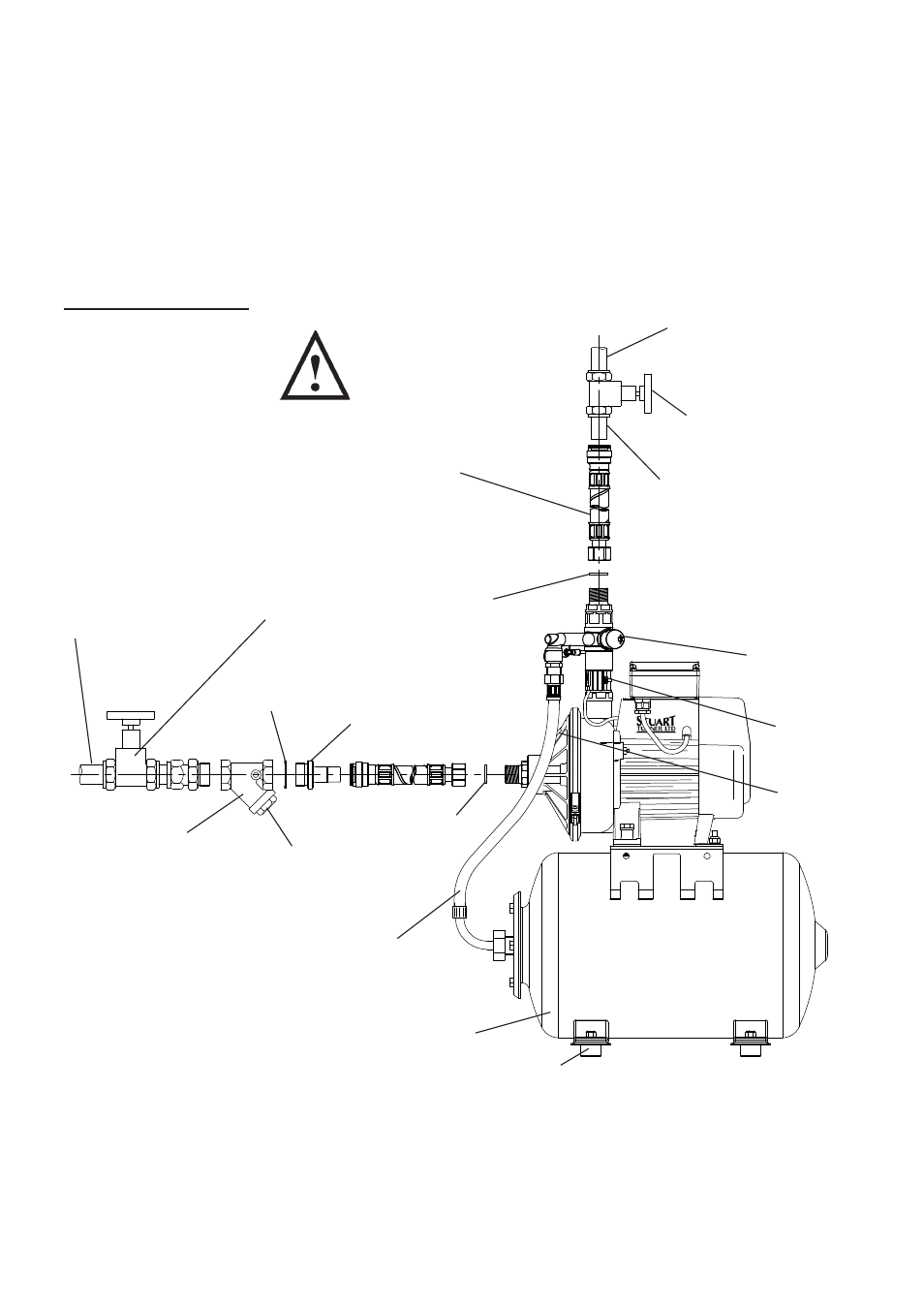

Pump Connections (General)

The pump set should not be screwed down, ensure anti-vibration feet and flexible

hoses are used.

Cont ...

Fig. 8

22 mm copper

outlet pipework

(discharge).

22 mm isolating valve and

fittings (not supplied). To

allow easy pump service.

Short 22 mm copper pipe tails to

connect between isolating valve

and flexible pipe. Ensure all burrs

are removed prior to installation

into push-in connector. Tube

must be fully pushed home into

the flexible push-in connector.

Pressure switch.

Flow switch.

Priming plug.

Anti-vibration mounting foot.

Pressure vessel.

Flexible hose.

Sealing

Washer

Filter plug (removal

of this plug enables

internal gauze filter

to be cleaned).

1 ” Inlet ‘Y’

type strainer.

28 mm copper

inlet pipework

(suction).

28 mm isolating

valve and fittings

(not supplied).

Sealing

washer.

22 mm tailend x 1 ”

male adaptor.

Sealing

Washer

22 mm flexible pipes with push-

in connections. Ensure that

connections are fully pushed

home into mating connector

and that hoses are kept as

straight as possible. In the case of horizontal

feeds use a 22 mm John Guest stem elbow

(not supplied). Do not bend the hose more

than 30° as they may become damaged,

transmit noise or leak.