Typical installation, Step 2 pump location (general), Step 1 pre-installation check – Stuart Turner 3.2 bar PS User Manual

Page 2

- 2 -

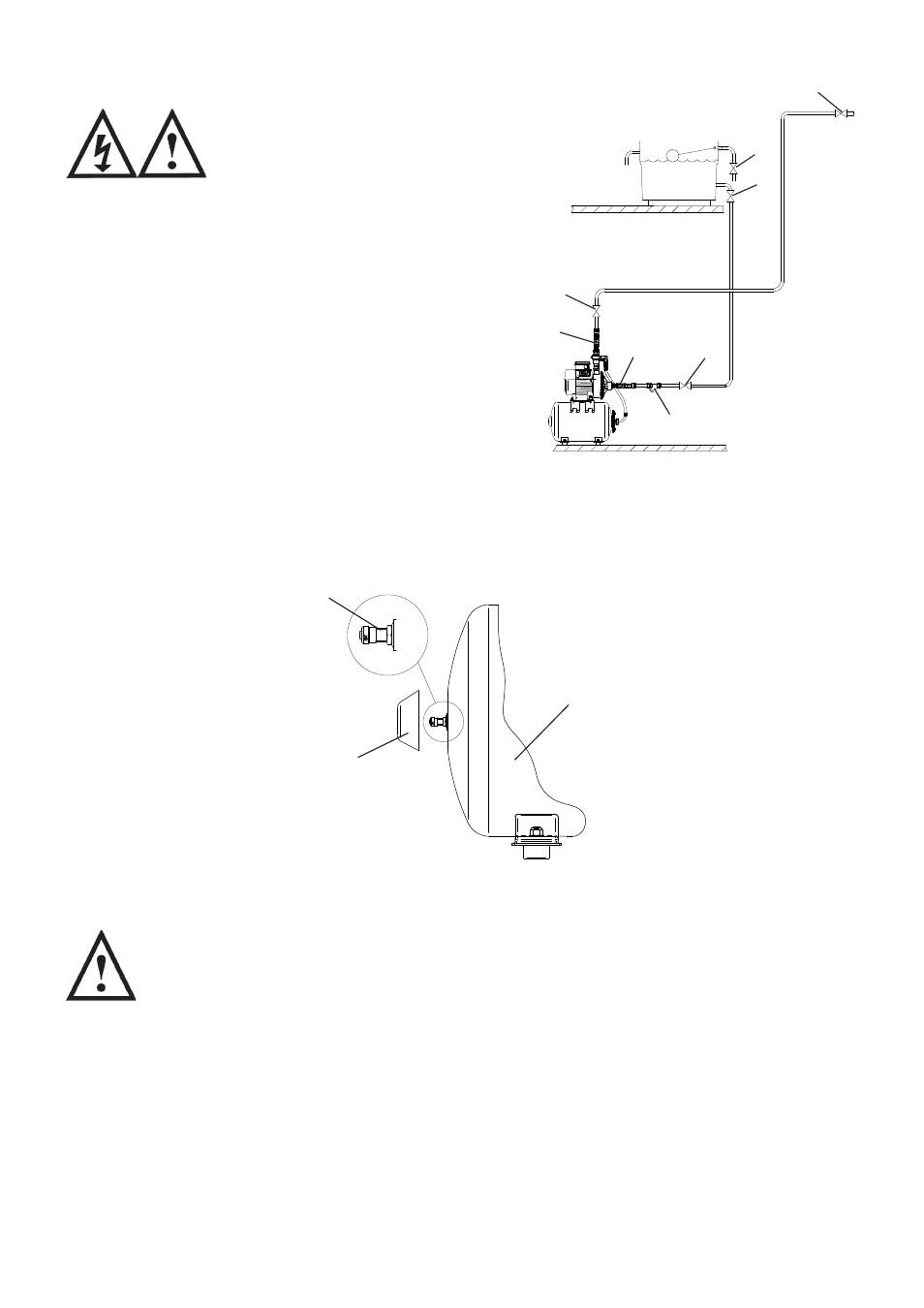

TYPICAL INSTALLATION

The plumbing installation must

comply with the following:

The Water Supply (Water Fittings) Regulations 1999.

BS6700 and building regulations.

Be installed by a competent person.

If in doubt contact Stuart Turner Ltd

STEP 2 PUMP LOCATION (GENERAL)

WARNINGS:

The pump must not be located where the inlet pressure to the pump is

greater than permitted.

Care should be taken to protect pump from frost and freezing,

particularly when located in a loft installation.

Pump Location

If possible site the pump in a location where in the unlikely event of a

water leak, any spillage is contained or routed to avoid electrics or

areas sensitive to water damage.

The motor casing can become very hot under normal operating

conditions, care should be taken to ensure it cannot be touched

during

operation.

Ensure all components in the down-stream system to be pressurised

are suitably rated to accommodate the final system working pressure.

This diagram should be used for

schematic reference only

1: Isolating valve

2: Inlet strainer

3: Flexible hose

STEP 1 PRE-INSTALLATION CHECK

Your pump set comprises of two major parts, the main pump and pressure vessel. The

pressure vessel is pre-charged with air at the factory to 140 kPa (1.4 bar or 20.3 psi).

This pressure should be checked at the Schrader valve using a tyre pressure gauge and

adjusted if necessary using a car or bicycle pump prior to installation.

PUMPS

1

1

1

1

1

2

3

3

Fig. 1

Fig. 2

Pressure

Vessel

Schrader

valve

Plastic

Protector Cap

(unscrew to

access valve)