Stuart Turner 3.2 bar PS User Manual

Page 5

- 5 -

Pipework Connections (Connection between pump and down-stream services to

be boosted)

This should run as far as possible in 22 mm copper tube. Any bend requirements should

be achieved by hand drawing the tube or by use of the appropriate bend fittings. Pipework

should only be reduced to 15 mm copper if necessary when entering any terminal fittings

of this size. By this method the maximum performance of the pump will be maintained. All

pipework should be securely clipped.

STEP 5 PUMP CONNECTIONS

(Release And Connection Of Push-in Connectors)

WARNINGS: (Push-in Connectors)

Do not use stainless steel, chrome or nickel plated pipe with Stuart

Turner push-in plumbing connections.

Do not introduce solder flux into the joint or surrounding area as

connectors will be attacked and may fail.

All solder joints should be completed and flux residues removed

before final connection to push-in connections, either on flexible hose

or pump head.

Do not allow contact with oil or cellulose based paints, paint thinners

or strippers, acid based descalents or aggressive cleaning agents.

Hose to Pump

The pump inlet and outlet ports have factory assembled fittings which are specifically

designed for connection to the G ¾ female running nuts on the flexible hoses. The hose

end is fitted with a rubber sealing washer which is held captive within the nut assembly.

Locate the hose into position and screw the nut fully onto the fitting by hand. finally nip

tight with a spanner (4/5 Nm) for a water tight seal

(do not overtighten).

Cont ...

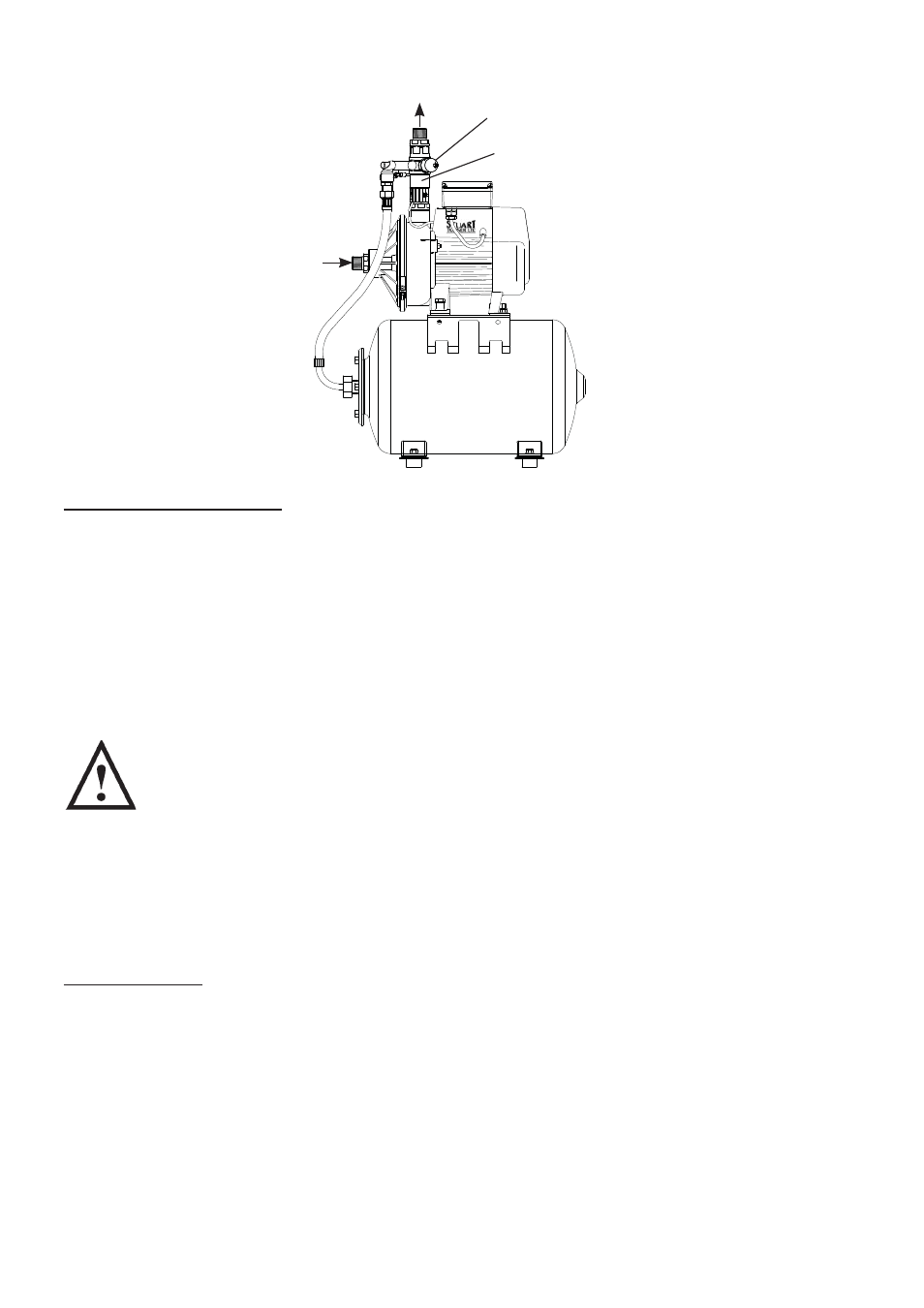

Fig. 4

Outlet

Inlet

Pressure Switch

Flow Switch