Stuart Turner Stuart Flange SE User Manual

Stuart Turner Pumps

Issue No: 1014/2-01

Pt. No. 19817

STUART FLANGE SIDE ENTRY (SE)

INSTALLATION INSTRUCTIONS

1. Select a position on the hot water cylinder away from any immersion heater port as water drawn from

around an immersion heater could be aerated.

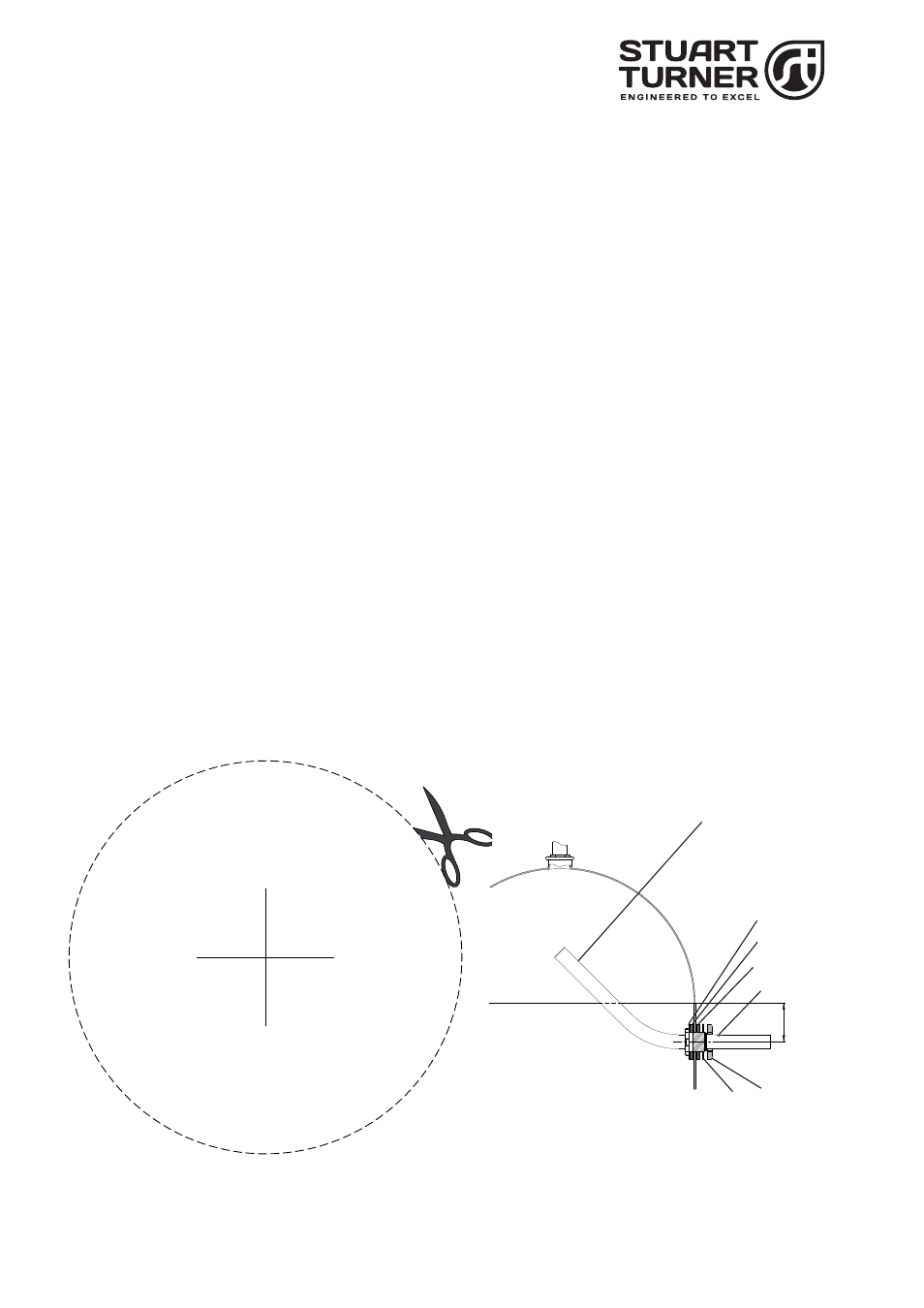

2. Mark the centre point of the proposed hole approx. 60 mm below the cylinder seam and cut a 75 mm

square out of the insulating material.

3. Lower the water level in the cylinder to a point below the position of the proposed hole.

4. Using the Template supplied mark out the centre-point of the hole and a circle 60 mm dia.

5. Using the shell cutter supplied cut a hole using the marked centre-point (38 mm dia.). Clean away any

burrs from the cut edge and remove any limescale deposits from the inside face of the cylinder to ensure a

clean sealing face.

6. Remove Nut and Washers from Flange Assembly (1). Manipulate the Flange Assembly (1) through the

hole cut in the cylinder by holing at an angle and rotating. Check that flange tube does not interfere with

the immersion heater coil and if necessary reduce length of tube.

7. Open up the gap in the Split Washer (2) and slide onto the Flange Assembly (1). Feed slit end through

cylinder wall and rotate to position on inside of cylinder. Locate over threaded section of flange and pull

Flange Assembly (1) up against inside wall of cylinder to close gap in washer.

8. Now slide Sealing Washer (3) onto flange and feed through hole to position on threaded section of Flange

Assembly

(1).

9. Fit second Sealing Washer (4) on Clamp Washer (5) over flange and push up against cylinder wall.

10. Apply a bead of clear silicon sealant around inner diameter of Clamp Washer (5). Fit Nut (6) and hand

tighten.

DO NOT APPLY SEALANT TO SEALING WASHER.

11. Ensure that the RED DOT on the Flange Assembly (1) is positioned upper-most and that the assembly is

central within the circle marked on the cylinder. Lightly tighten Nut (6) to clamp up assembly.

DO NOT

OVER

TIGHTEN.

12. Adjust length of protruding pipework if required and complete pipework ensuring that isolating valve is fitted.

When using compression fittings ensure that the Flange Assembly (1) is gripped to avoid rotating. Close

valve, re-fill system and check for leaks. If necessary tighten Nut (6) to achieve seal.

1

2

3

4

Red Dot

60 mm

min

6

5

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

[email protected] www.stuart-turner.co.uk

V.A.T. REG. No. 199 0987 92. Registered in England No. 88368. Registered Offi ce: Market Place, Henley-on-Thames