13) span adjustment, 13)span adjustment -14 – Yokogawa EJA310A User Manual

Page 47

IM 01C21D01-01E

8-14

8. BRAIN TERMINAL BT200 OPERATION

(c) Zero Point Adjustment Using the External Zero

Adjustment Screw

• Enabling/inhibiting of zero point adjustment using

the external zero-adjustment screw on the transmitter

(J20: EXT ZERO ADJ)

Follow the procedure below to enable or inhibit zero

point adjustment from the zero-adjustment screw on

the transmitter.

This is set to “ENABLE” when the instrument is

shipped.

• Example: Inhibiting zero adjustment by the

external zero-adjustment screw

ESC

SET

J20:EXIT ZERO ADJ

ENABLE

< ENABLE >

< INHIBIT>

Use the or key to

select “INHIBIT.”

Press the key twice to

enter the setting.

F0831.EPS

• Zero point adjustment using external zero-adjust-

ment screw on the transmitter

Turn the zero-adjustment screw on the outside of the

transmitter case using a slotted screwdriver. Turn the

screw to the right to increase the zero point or to the

left to decrease the zero output; the zero adjusts in

increments of 0.01% of the range setting.

Note that the amount of adjustment to the zero point

changes according to the speed at which the screw is

turned. To make fine adjustments, turn the screw

slowly; to make coarse adjustments, turn the screw

quickly.

Note: When a zero point adjustment has been made, do not turn

off the transmitter less than 30 seconds after adjustment.

(13) Span Adjustment

Each DPharp EJA series transmitter is factory

characterized according to the specification. Mount-

ing position effects or zero shifts caused by static

pressure are typically compensated by a zero adjust-

ment.

A span adjustment is a function to correct the slope

error from a zero point in characterizing 100% point

(HRV). This function can be used when span drifts

may be caused or characterization to the specific

pressure standard is required.

Therefore, the zero point adjustment should always

be performed before the upper point adjustment in

order to maintain the pitch between zero and 100%

points within the calibration range.

You can manually perform the trimming procedure

by using J15: SPAN ADJ.

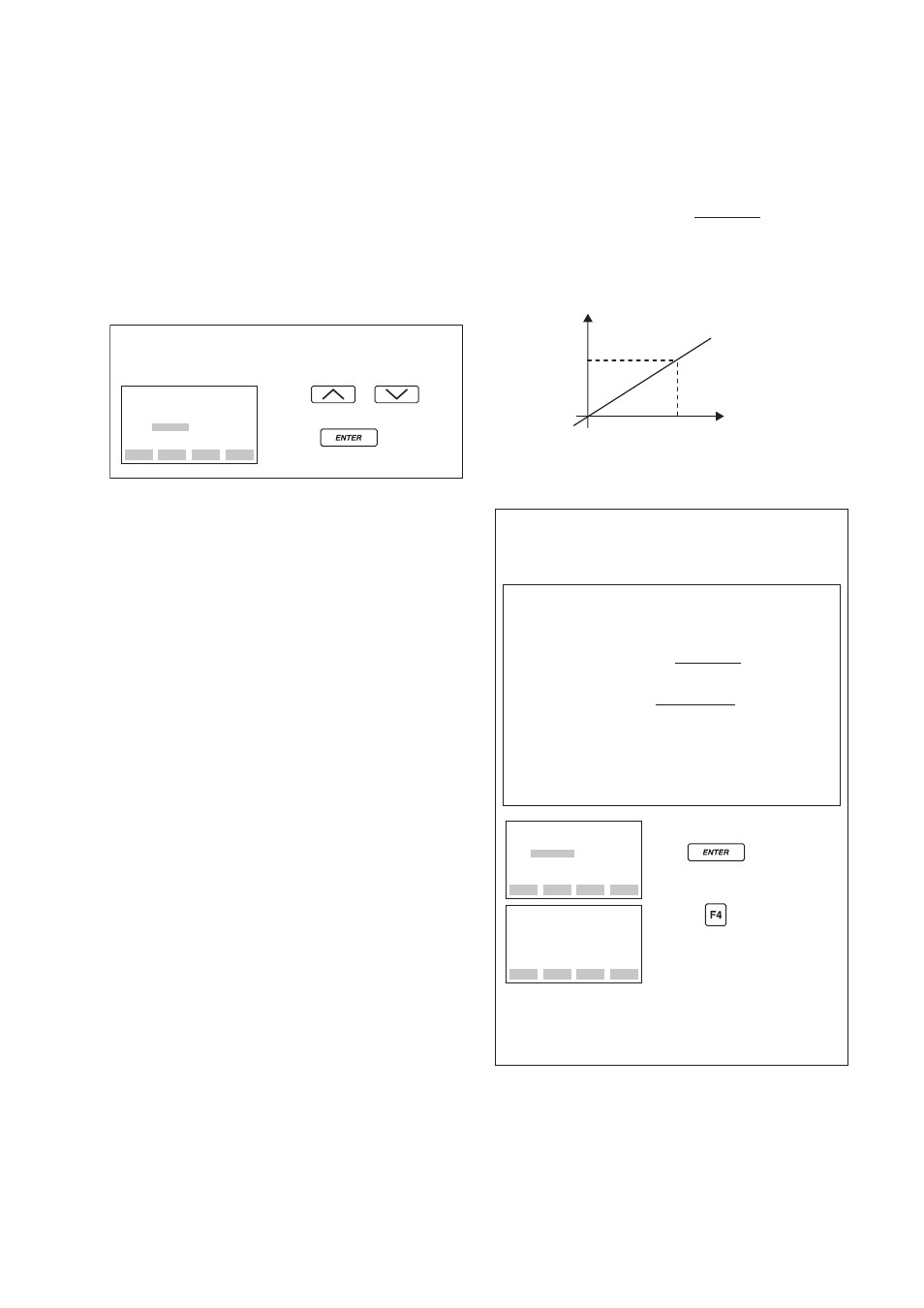

• Span adjustment value

The span adjustment value is calculated as follows.

Span adjustment value (%) =

P

1

: Actual differential pressure/pressure value

A40: Input (indicated as the value after zeroing)

Measurement pressure

Applied pressure

P

1

Ϫ A40

P

1

ϫ

100

A40

P

1

0

F0846.EPS

• Example: For the range of 0 to 30 kPa.

A40: INPUT = 30.15 kPa

J15: SPAN ADJ = 0.15 %

Suppose that a standard pressure of 30 kPa is applied and

the value of the parameter of A40: INPUT is 30.15 kPa.

Firstly, obtain the slope error for the span as follows;

Add

Ϫ0.5% to 0.15% of the current value to calculate the

accumulated span adjustment value.

0.15

ϩ (Ϫ0.50) = Ϫ0.35

F0847.EPS

FEED

NO

OK

SET

J15:SPAN ADJ

-0.35 %

ESC

CLR

DEL

SET

J15:SPAN ADJ

0.15 %

- 0.35

Set

Ϫ0.35.

Press key twice.

Press the (OK) key.

30.00

Ϫ30.15

30.00

ϫ 100 = Ϫ0.5 (%)

ϭ

Span adjustment value (%) =

Note: Enter 0.00 to J15: SPAN ADJ to reset the

span adjustment to the initial value at the

shipment.

P

1

Ϫ

A40

P

1

ϫ100