2 zero point adjustment, Zero point adjustment -2 – Yokogawa EJA310A User Manual

Page 30

IM 01C21D01-01E

7-2

7. OPERATION

Using the integral indicator

• If the wiring system is faulty, the display stays blank.

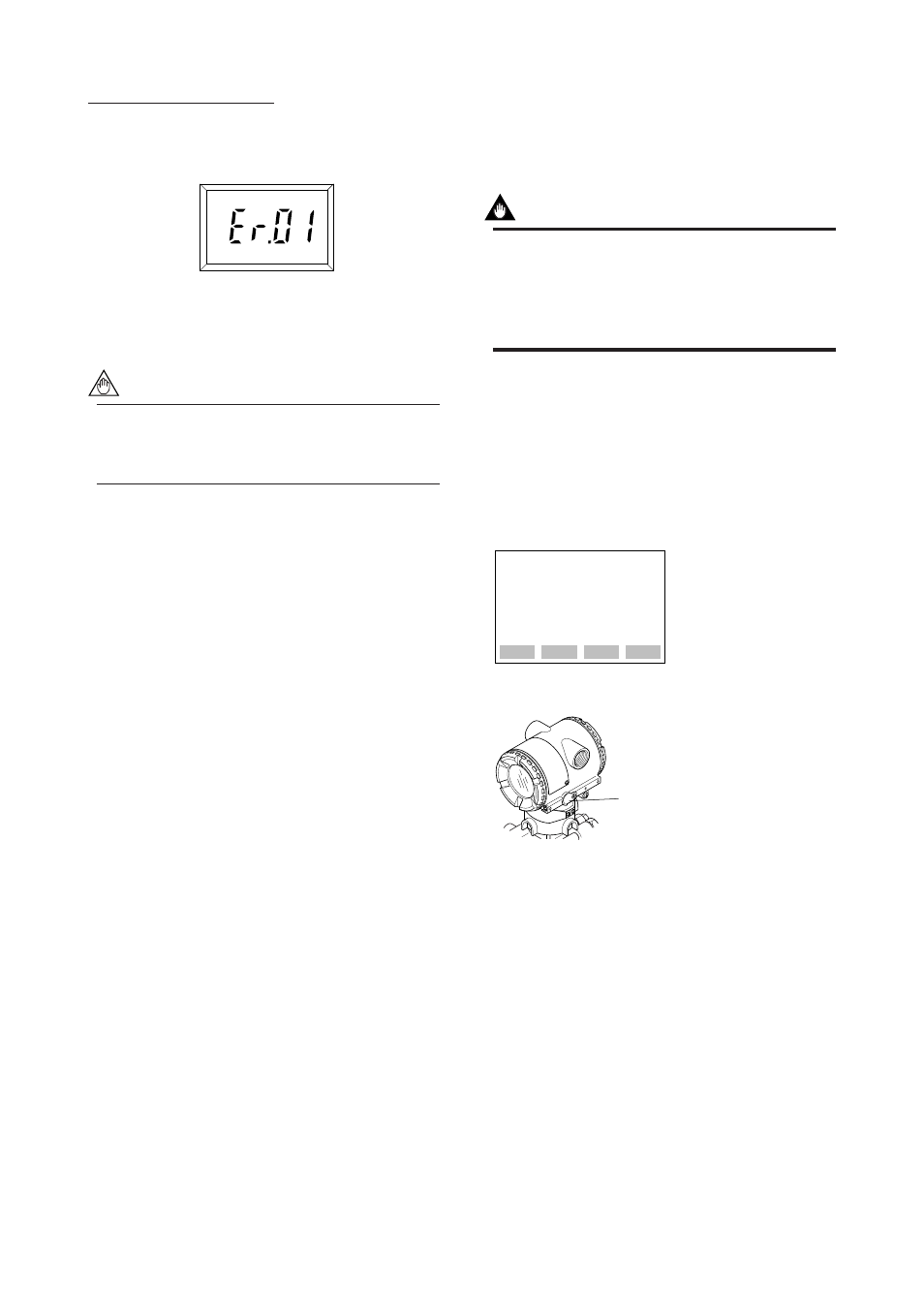

• If the transmitter is faulty, an error code will appear

on the display according to the nature of the error.

Self-diagnostic error on

the integral indicator

(Faulty transmitter)

F0703.EPS

NOTE

If any of the error indications above appears on

the display of the integral indicator or BT200,

refer to Subsection 8.5.2 for corrective action.

Verify and Change Transmitter Parameter

Setting and Values

The following parameters are the minimum settings

required for operation. The transmitter has been

shipped with these parameters. To confirm or change

the values, see Subsection 8.3.3.

• Measuring range..........See Subsection 8.3.3 (2)

• Operation mode...........See Subsection 8.3.3 (7)

7.2 Zero Point Adjustment

Adjust the zero point after operating preparation is

completed.

IMPORTANT

Do not turn off the power to the transmitter

immediately after a zero adjustment. Powering

off within 30 seconds after a zero adjustment will

return the adjustment back to the previous

settings.

The zero point adjustment can be made in either way:

using the zero-adjustment screw of the transmitter or

the BT200 operation.

For output signal checking, display the parameter A10:

OUTPUT (%) in the BT200.

Output signal (%)

display

PARAM

A10:OUTPUT(%)

0.0 %

A11:ENGR OUTPUT

A20:AMP TEMP

DATA

DIAG

PRNT

ESC

F0704.EPS

Zero-adjustment

screw

᭹BT200

᭹Zero-adjustment Screw

After reviewing this parameter you are prepared to

adjust the zero point. When making the zero adjust-

ment on a pressure transmitter, the process pressure

value does not have to be set to the low limit of the

measurement range (0%). In such case, adjust the

transmitter output signal to the actual measured value

obtained from a high-accuracy pressure measuring

instrument.