2 setting parameters using the bt200, 1 parameter usage and selection, Setting parameters using the bt200 -4 3.2.1 – Yokogawa EJA440E User Manual

Page 12: Parameter usage and selection -4, Important

<3. Operation>

3-4

IM 01C25T03-01E

3.2 Setting Parameters Using

the BT200

3.2.1 Parameter Usage and Selection

Before setting a parameter, please see the following

table for a summary of how and when each

parameter is used.

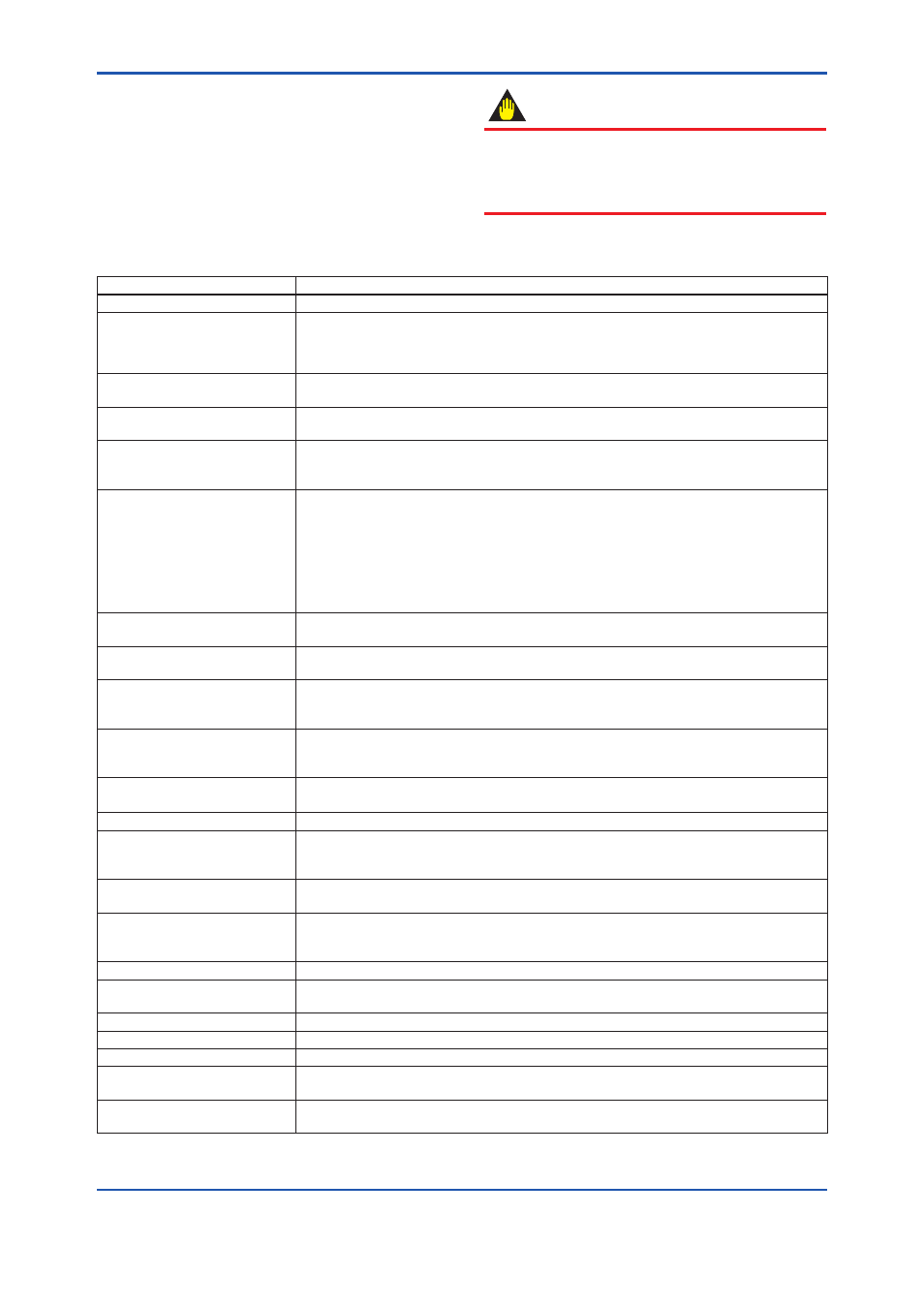

Table 3.1

Parameter Usage and Selection

Setup item

Description

Tag No. setup

►P.3-6 Sets the Tag No. (using 16 alphanumeric characters).

Calibration range setup

►P.3-6

Sets the calibration range for 4 to 20 mA DC. Sets the following items: range unit, input value at 4

mA DC (LRV), input value at 20 mA DC (URV), and decimal point position.

Note: LRV and URV can be specified with range value specifications up to 5 digits (excluding any

decimal point) within the range of –32000 to 32000.

Damping time constant setup

►P.3-7

Adjusts the output response speed for 4 to 20 mA DC at amplifier.

Can be set from 0.50 to 100.00 s. (from 0.00 to 100.00 s with quick response mode on)

Output and integral indicator

display mode setup

►P.3-8

Sets modes for output signal and integral indicator to Linear mode (proportional to input differential

pressure) or to Square root mode (proportional to flow).

Output signal low cut mode setup

►P.3-8

Used mainly to stabilize output near 0% if the output signal is square root mode.

Two modes are available: forcing output to 0% for input below a specific value, or changing to

proportional output for input below a specific value.

Integral indicator display function

►P.3-9

Available from the following 5 types of integral indicator scale ranges and units:

input pressure, % of range, user set scale, input static pressure, % of static pressure range, and

alternating among any four of the above.

Configure the following when using the user set scale;

user set scale setting, unit (BT200 only), display value at 4 mA DC (LRV), and display value at

20 mA DC (URV).

Note: LRV and URV can be specified with range value specifications up to 5 digits (excluding any

decimal point) within the range of –32000 to 32000.

Static pressure setup

►P.3-11

Sets the parameters concerned with static pressure such as unit, calibration range, upper and

lower range values, decimal point position, damping time constant.

Unit setup for displayed

temperature

►P.3-11

Sets the unit for temperatures displayed on the BT200.

Operation mode (normal/reverse

signal) setup

►P.3-11

Reverses the direction for 4 to 20 mA DC output relative to input.

Reverse mode is used for applications in which safety requires that output be driven toward 20 mA

if input is lost.

Impulse line connection orientation

(higher pressure on right/left side)

setup

►P.3-11

Used where installation conditions make it imperative to connect high pressure side impulse line to

low pressure side of transmitter. Reversal of orientation should be dealt with by reversing impulse

line wherever possible. Use this function only where there is no alternative.

CPU Failure burnout direction and

hardware write protect

►P.3-11

Displays the status of 4 to 20 mA DC output when a CPU fails. The direction is selectable by the

hardware switch on the amplifier. It also physically prevents parameter access

Software write protect

►P.3-12 Configured data can be protected by setting a password.

Output status setup when a

hardware error occurs

►P.3-13

Sets the status of the 4 to 20 mA DC output when an abnormal status is detected with the capsule

or the amplifier as the result of self-diagnosis. Either the last held, high limit, or low limit values

status, can be selected.

Bi-directional flow measurement

►P.3-13

Used to measure bi-directional flows. Output at zero flow is 12 mA DC, with output range equally

divided between forward and reverse flow. Can be used with square root mode.

Range change while applying

actual inputs

►P.3-13

Range for 4 to 20 mA DC signal is set with actual input applied. Sets 20 mA DC output precisely

with respect to user’s reference instrument output. Note that the transmitter is calibrated with high

accuracy before shipment, so span should be set using the normal range setup.

Sensor trim

►P.3-14 Adjusts zero point and span of the sensor.

Test output (fixed current output)

setup

►P.3-17

Used for loop checks.

Output can be set freely from –2.50% to 110.00% in 0.01% steps.

Signal characterizer

►P.3-17 Used to compensate the output for the non-linear application.

Process alarm

►P.3-18 Used for alarm generation on the integral indicator.

Status output

►P.3-18 Outputs an on/off digital signal based on the settings of process alarm.

Capillary fill fluid density

compensation

►P.3-19

Compensates the zero shift by the ambient temperature effect on the capillary tubes.

User memo fields

►P.3-20

Allows user to enter up to 3 items, each containing any combination of up to 16 alphanumeric

characters.

IMPORTANT

After setting and sending data with the

BT200, wait 30 seconds before turning off the

transmitter. If it is turned off too soon, the settings

will not be stored in the transmitter.