Cable installation / hydraulic systems, Typical layout – Ramsey Winch HSW-10000 RAM-LOK LOW MOUNT User Manual

Page 6

4

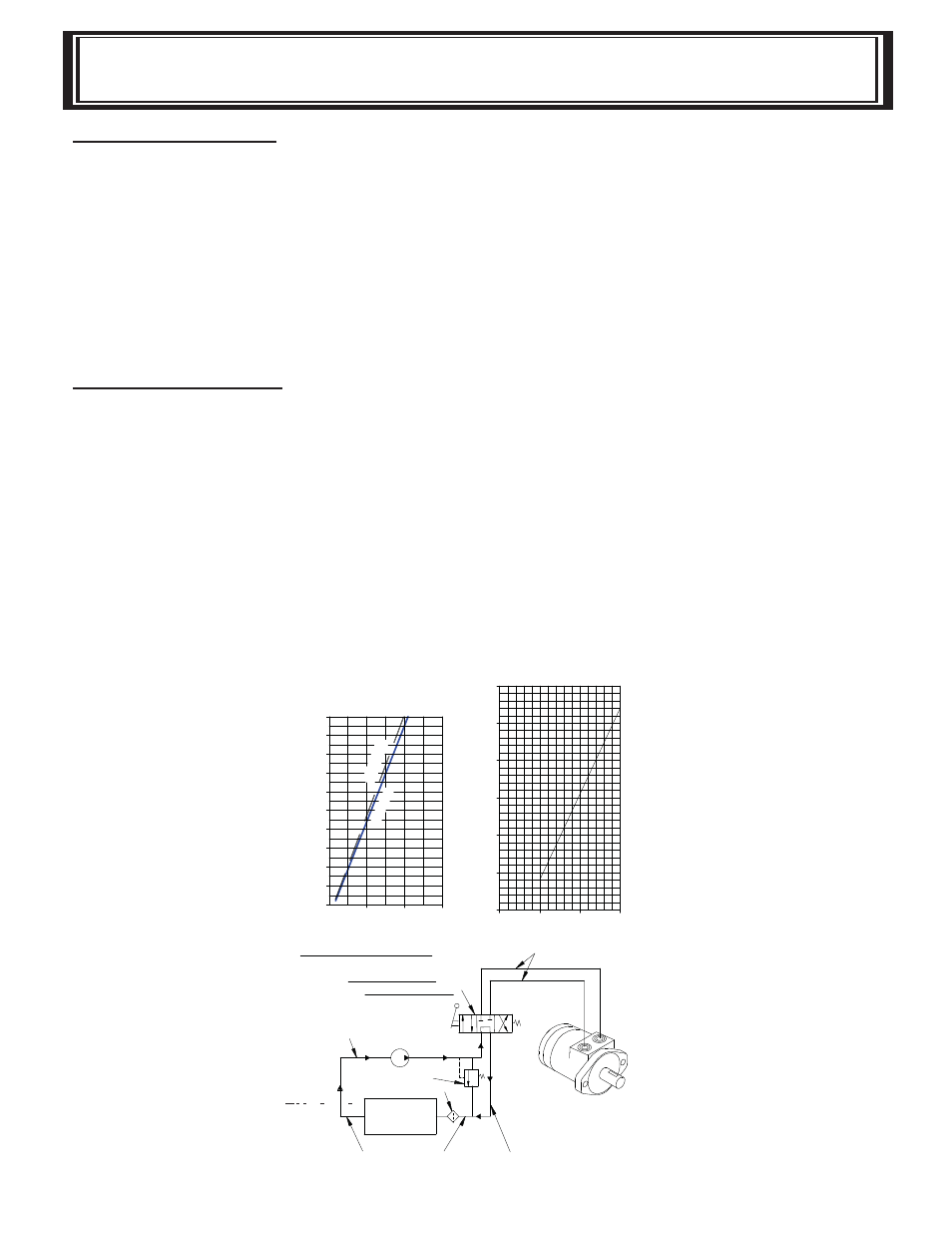

HYDRAULIC SYSTEMS

Refer to performance charts, below, to properly match your hydraulic system to the HDG-350

winch performance. The charts consist of:

1. Line pull (lbs.) first layer vs. working pressure (P.S.I.). STATIC refers to lifting a suspended

load from rest; DYNAMIC refers to maintaining the motion of a moving load.

2. Line speed, first layer (F.P.M.) vs. gallons per minute (G.P.M.).

Performance based on a motor displacement of 3.6 cubic inches with 15 GPM maximum flow

rate.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of cable,

opposite hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the ½”” dia. hole in drum barrel. Secure

cable to drum barrel, using setscrew furnished with winch. TIGHTEN SETSCREW

SECURELY.

3. Carefully run winch in the “reel-in” direction. Keeping tension on end of cable, spool all the

cable onto the cable drum, taking care to form neatly wrapped layers.

CABLE INSTALLATION / HYDRAULIC SYSTEMS

30

25

20

35

10

15

LINE PULL-FIRST

LA

YER (LB.)

LINE SPEED-FIRST

LA

YER (FPM)

ST

A

TIC

WORKING PRESSURE, PSI

0

1,000

0

1,000

3,000

2,000

5,000

4,000

3,000

2,000

5

HSW-10,000 PERFORMANCE

10,000 LB. DUTY RATING

30:1 GEAR RATIO

7,000

6,000

8,000

FLOW (GPM)

5

0

10

15

WITH 3.6 C.I.D. MOTOR

9,000

10,000

DYNAMIC

PUMP

LOW PRESSURE LINES

RESERVOIR

FLUID

FLUID FILTER

RELIEF VALVE

CONTROL VALVE

EMERGENCY STOP

TYPICAL LAYOUT

3 POSITION 4 WAY

CYLINDER SPOOL

PUMP INLET LINE

(SUCTION)

WINCH MOTOR

HYDRAULIC

(.75 I.D. MINIMUM)

LOW PRESSURE LINES

HIGH PRESSURE LINES

(.50 I.D. MINIMUM)