Electrical connections, Adjusting the oil cooled worm brake, Cable installation – Ramsey Winch DC-200 SERIES LEVER User Manual

Page 6: Winch mounting

4

It is most important that this winch be mounted securely so that the three major sections (the

clutch housing end, the cable drum and the gear housing end) are properly aligned.

All standard model DC-200 Series Winches are furnished with recommended mounting angles.

Angle size is 1/4 x 2-1/2 x 2-1/2 x 36” Lg. high strength (50,000 PSI yield) steel angle.

ELECTRICAL CONNECTIONS

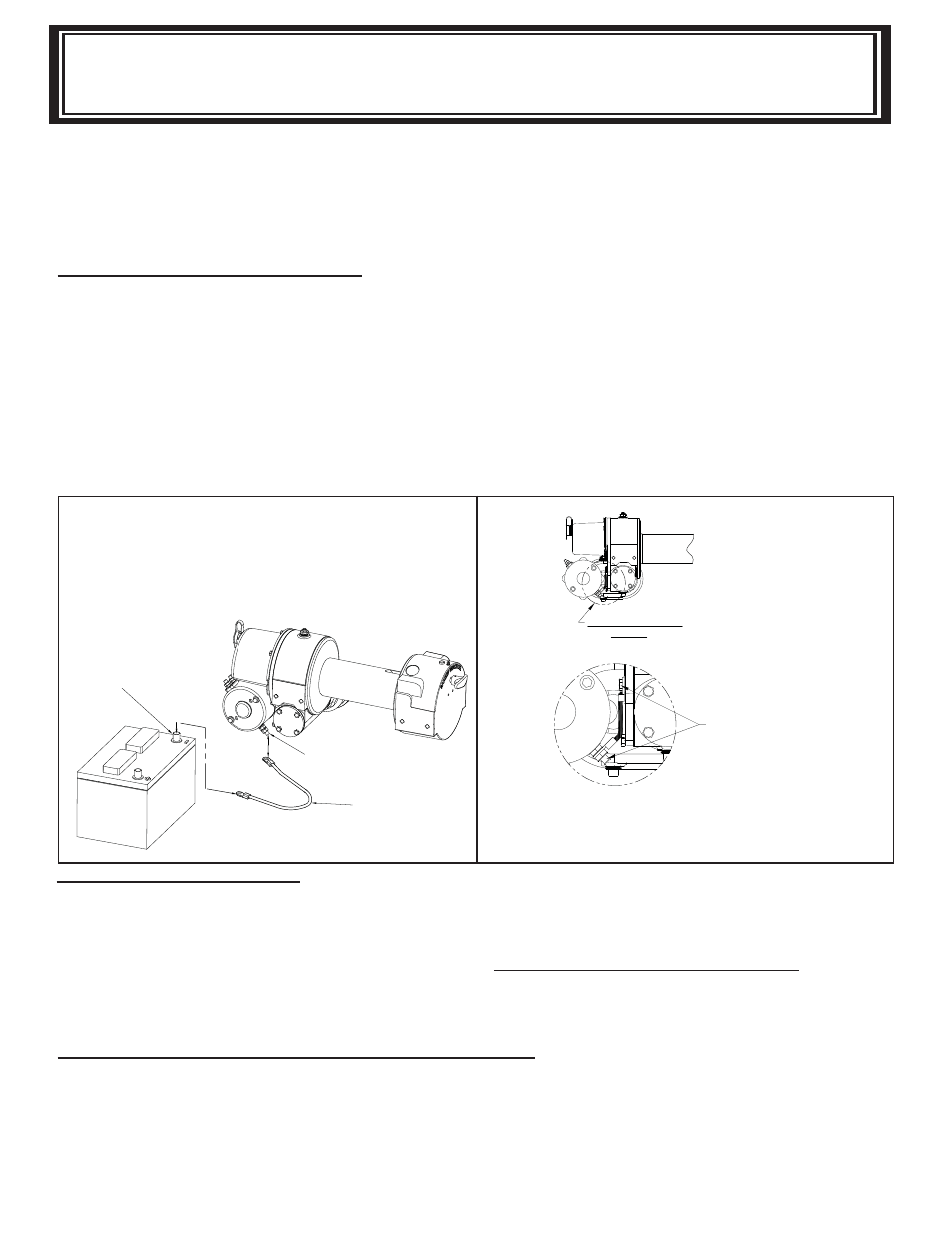

See dimensional drawing on page 17. Using a power cable with appropriate end terminals, con-

nect the positive (+) battery terminal to the 5/16” dia. stud on the plastic solenoid cover on the

winch. IMPORTANT: Hold inner nut on stud with a wrench while tightening outer nut. Using a

ground cable with appropriate end terminals, connect the negative(-) battery terminal to the mo-

tor isolated ground terminal. In applications where the chassis is non-grounded, a jumper wire

(#440315) will be required between the winch and the motor ground. This ground is required to

insure a suffi cient ground to operate the solenoid assembly (See Diagram Below). For distances up

to 15 feet from battery to winch, use #2 Ga. wire for the above connections. For distances greater

than 15 feet, use wire larger than #2 Ga.

ADJUSTING THE OIL COOLED WORM BRAKE

The oil-cooled, fully adjustable, automatic safety brake operates in the worm housing lubricant, all

parts being submerged in oil. When the brake wears to the point that the load begins to drift, the

brake can be adjusted as follows:

1. Loosen the lock nut on the adjusting screw.

SEE ILLUSTRATION

JUMPER CABLE (#440315) MUST BE

INSTALLED ON WINCH FROM MOTOR

ISOLATED GROUND STUD TO GEAR

HOUSING COVER BOLT AS SHOWN

FOR NON GROUNDED CHASSIS

APPLICATIONS.

BELOW

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of cable,

opposite hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the 7/16” dia. hole in drum barrel. Secure cable to

drum barrel, using setscrew furnished with winch. TIGHTEN SETSCREW SECURELY.

3. Carefully run winch in the “reel-in” direction. Keeping tension on end of cable, spool all the cable

onto the cable drum, taking care to form neatly wrapped layers.

NEGATIVE BATTERY POST

GROUND CABLE

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL TO THE

NEGATIVE BATTERY POST.

(SEE DIAGRAM BELOW)

ISOLATED GROUND

TERMINAL

Isolated Motor Ground

For non-grounded chassis applications

a jumper wire (#440315) is required to

ground the solenoid assembly.

WINCH MOUNTING