Ramsey Winch DC-200 SERIES LEVER User Manual

Page 18

16

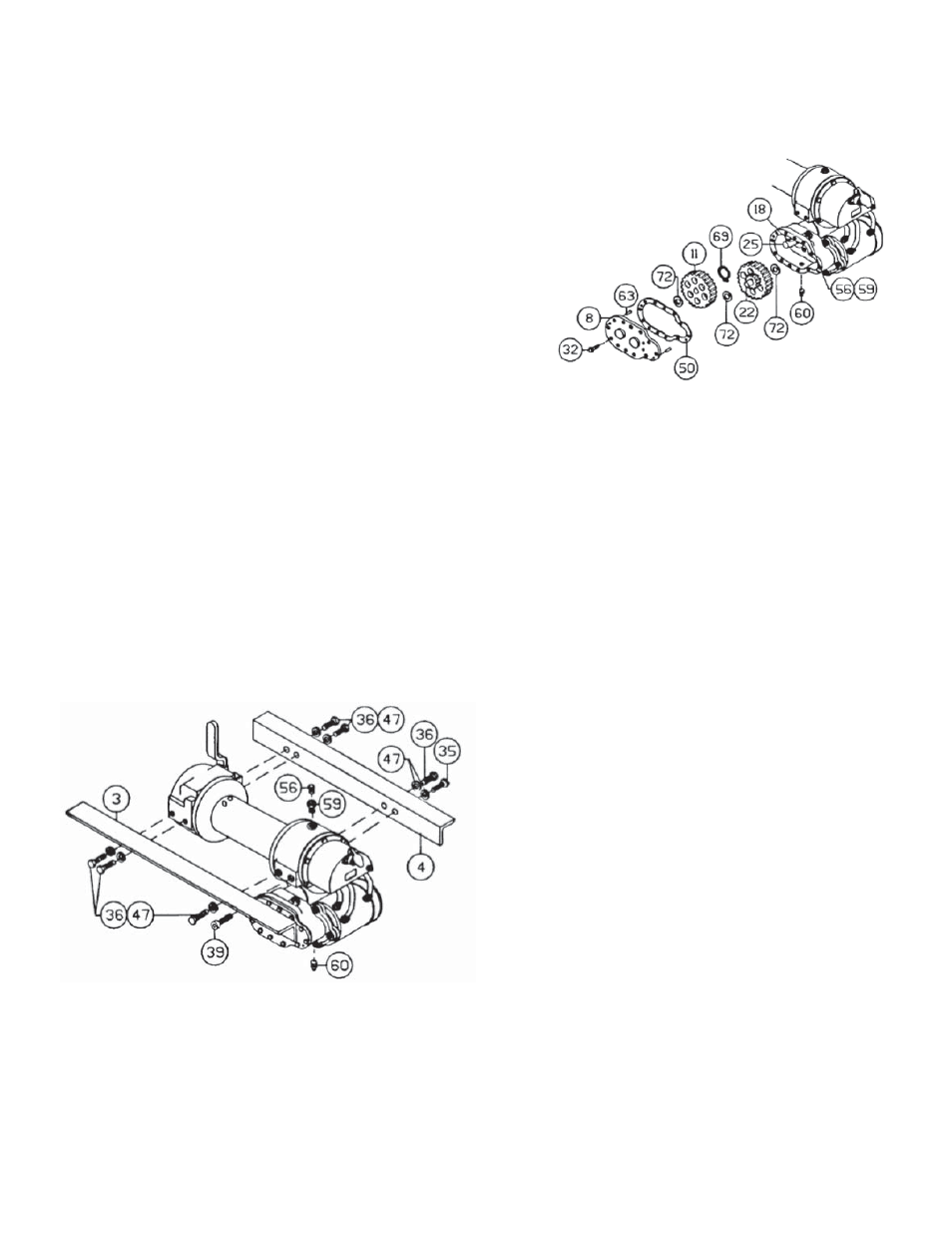

20. Attach mounting angles (items #3 & #4)

using six capscrews (item #36) with lock-

washers and capscrews (items #39 &

#35). Torque capscrews to 34 ft. lb. (46

Nm.) each. Insert plug (item #60) into

bottom of gear housing. Permatex may

be applied to threads to help prevent

leakage.

Pour 3/4 pint of EP 140 gear oil into

housing through hole in top of housing.

Insert relief fi tting (item #56) into reduc-

er (item #59) . Reducer should then be

placed into hole on top of gear housing.

Tighten fi tting and reducer securely.

19. Place snap ring (item #69) over end of worm shaft

(item #25) and set into snap ring groove. Insert key

(item #18) into keyway of worm shaft. Place

thrust washer (item #72) over each end of spur

gear shaft (item #22). Set spur gear shaft

assembly into bearing of spur gear housing. Slide

gear (item #11) and (item #72) thrust washer over

end of worm shaft (item #25). Insert pins (item

#63) into cover (item #8 ). Place gasket (item

#50) onto cover. Attach cover and gasket to spur

gear housing using twelve capscrews (item #32).

Torque capscrews to 8 ft. lb. (10.8 Nm.) each.

Insert plug (item #60) into bottom of spur gear

housing. Permatex may be applied to threads to

help prevent oil leakage.

Remove reducer and fi tting (items #56 & #59) from

top of spur gear housing. Pour 1/2 pint of SAE 20

weight motor oil into spur gear box.

Replace reducer and fi tting into top of spur gear

housing. Tighten reducer and fi tting securely.