Mechanical alignment, Electrical installation, Specifications – Warner Electric B30 Single Range Tensioncells User Manual

Page 8: Electrical zero adjustment

8

Warner Electric • 800-825-9050

P-2012-4 • 819-0404

Mechanical Alignment

Align the sectional measuring roll to avoid any

mechanical binding or friction. The measuring

roll must be level and perpendicular to the path

of the strip material for accurate measurement.

The Mechanical Stops are fixed for the required

travel of the Load Table.

Electrical Installation

(Read the entire electrical wiring procedure

before proceeding.)

1. Turn off all electrical power to the loadcell.

2. Use twisted four conductor signal cable,

Belden 9402 or equivalent, in grounded steel

conduit from the LVDTs to the control panel.

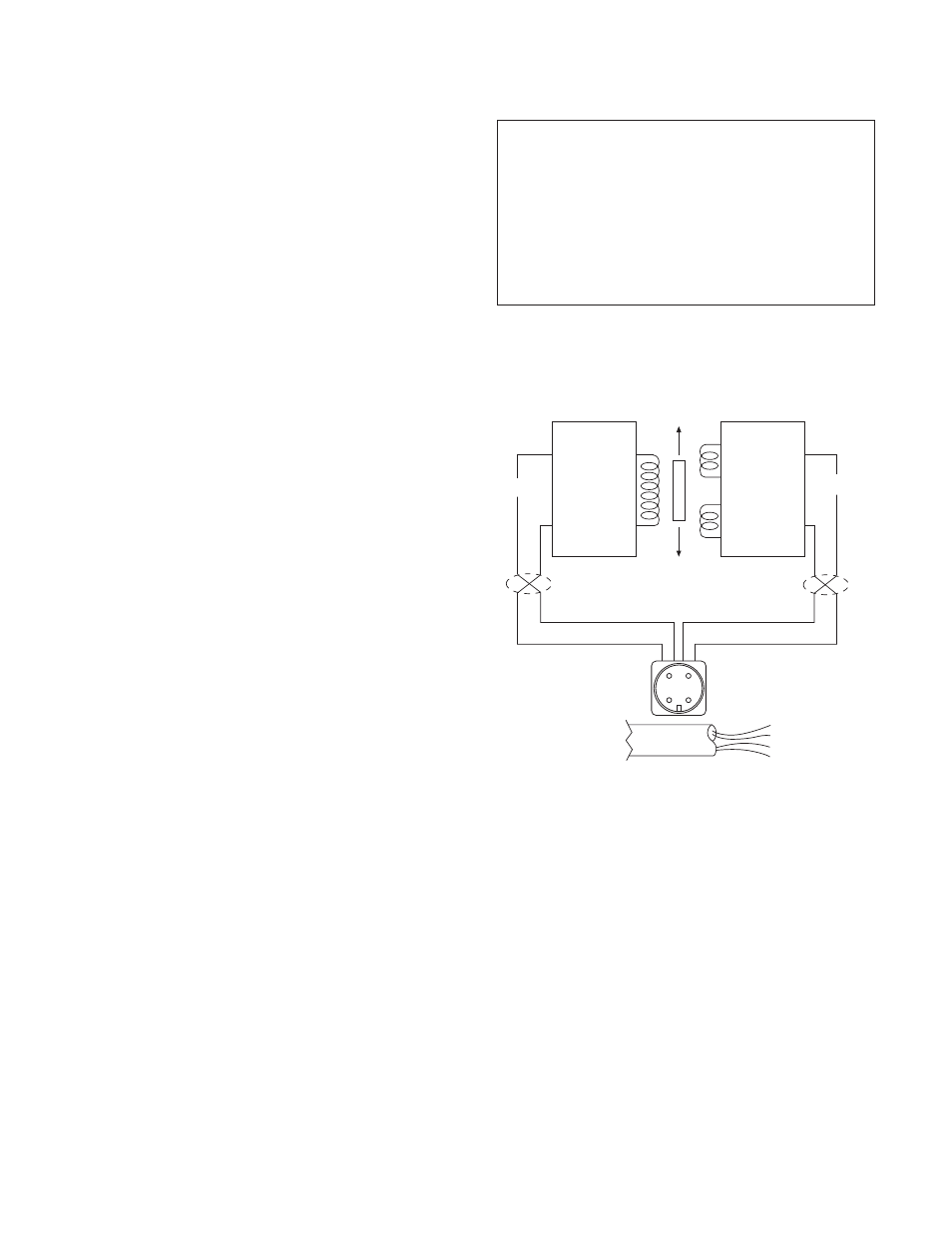

3. Observing correct polarity, connect the

positive (+) input lead to Pin A and the

negative (-) input lead to Pin B.

(See Figure 9)

4. Connect the positive (+) output lead to Pin D

and the negative (-) output lead to Pin C.

(See Figure 9)

5. Repeat Steps 1 through 4 of the electrical

wiring procedure for the Tensioncells

mounted on the other end of the measuring

roll.

Specifications

Type "K" 24 volt DC LVDT Specifications

Input . . . . . . . . . . . . . . . . . . . . . . . . .6-30 volts DC

Output . . .0.5-6.5 volts DC (nominal, open circuit)

Output Impedence . . . . . . . . . . . . . . . .2.5K ohms

Current Consumption . . . . . . . . . . . . . . . . .40 mA

Recommended Load . . . . . .100K ohms or greater

Max. Operating Temp . . . . . . . . . . . . . . . . . .250°F

NOTE: Warner Electric loadcells are calibrated

for 24 volt DC input voltage to provide a 0.5 to

6.5 volts DC output signal.

Electrical Zero Adjustment

(Read the complete Electrical Zero Adjustment

procedure before proceeding with the

adjustment.)

1. Disengage strip from the measuring roll so

that no tension force is applied to the

loadcell.

2. Connect a voltmeter to Pins C and D

(See Figure 9)

8. Position the roll with the Tensioncells on the

machine and fasten with the mounting bolts.

9. Rotate the Tensioncells to the proper

mounting angle and tighten the mounting

bolts.

10. Lock the locating pad for each Tensioncell

against the machine frame using the 1/4-20

x 1/2 socket head capscrew.

11. Tighten the shaft in the mounting block on

the W1 unit. (The shaft end at W2 is left free

to allow it to move as the shaft expands with

temperature changes).

Black - (2)

Red + (1)

Green (3)

Blue (4)

Input

Output

X Twisted Leads

A B

Oscillator

Demodulator

P1

S1

S2

X

X

When Supplied

with Cable

(1) Red + DC

(2) Black – DC

(3) Green – Signal

(4) White + Signal

C D

B

A

C

D

Figure 9