Mechanical, Electrical, Recalibration after installation – Warner Electric B30 Single Range Tensioncells User Manual

Page 10

10

Warner Electric • 800-825-9050

P-2012-4 • 819-0404

Mechanical

1. Has the tension measuring system been

changed?

a. An increase or decrease in strip tension

(Refer to A on the calibration sheet for

specified strip tension.)

b. An increase or decrease in the wrap angle.

(Refer to B on the calibration sheet for the

specified wrap angle.)

If the above parameters have been changed

enough to prevent the unit from operating within

the limits of the fixed. Mechanical Stops,

replacement of the tensioncells required. For

this modification, the Tensioncell should be

returned to the factory with complete

specifications.

2. Are the loadcells mounted securely?

3. Is tension measuring roll in proper alignment

and does it turn freely?

4. Are bearings and seals free of all binding and

stickiness? Are they worn?

Electrical

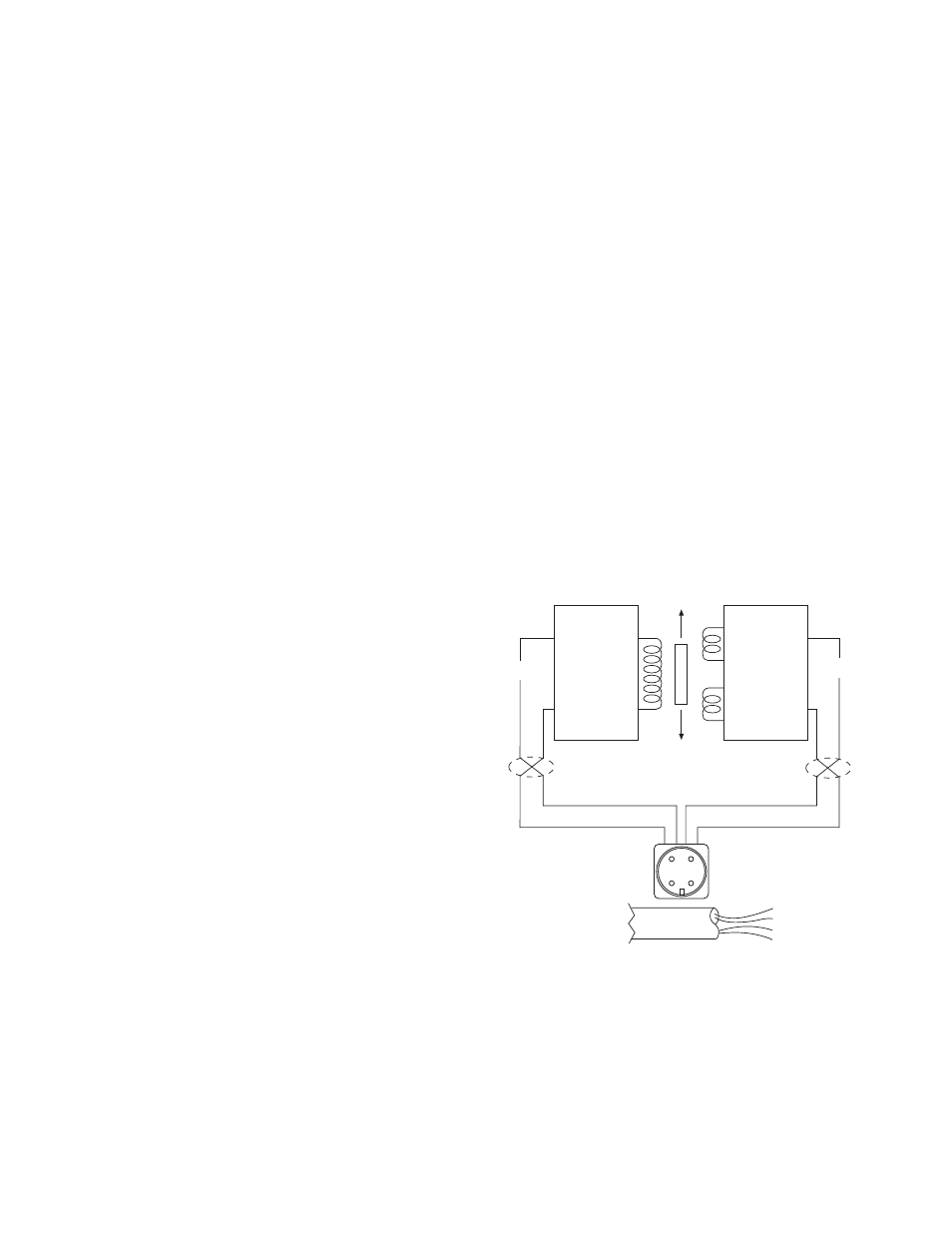

1. Are LVDTs receiving correct input voltage?

Check line voltage, fuses or circuit breakers,

and power switches. Check power supply

output and voltage to LVDTs.

2. Are all connections secure?

Check for continuity. Retighten all

connections. Recheck operation.

3. Are LVDTs open or shorted?

To check, turn off power and disconnect the input

and output leads. Check coil continuity and

resistance. (Refer to Figure 11)

a. Pin A to Pin B (Primary Coil) should be in

excess of 2 megohms.

b. Pin A or Pin B to LVDT shell should be in

excess of 5 megohms.

Recalibration after Installation

Wall Mounted Tensioncells can be relocated

around the center of the measuring roll. The

theory of this operation is explained in the

Description of Operation on Page 5. If this

procedure cannot accomplish the necessary

changes because the tension requirements are

extremely different than the original application,

it will be necessary to return the Tensioncells to

the factory for a different Tensioncell.

Black - (2)

Red + (1)

Green (3)

Blue (4)

Input

Output

X Twisted Leads

A B

Oscillator

Demodulator

P1

S1

S2

X

X

When Supplied

with Cable

(1) Red + DC

(2) Black – DC

(3) Green – Signal

(4) White + Signal

C D

B

A

C

D

Figure 11

c. Pin C to Pin D (Secondary Coil) should be

approximately 20,000 ohms.

d. Pin C or Pin D to LVDT shell should be in

excess of 5 megohms.

If LVDT circuits are open or shorted, replace the

Tensioncell LVDT. Contact Warner Electric with

Tensioncell model number and serial number.