Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 4

4

Warner Electric • 800-825-9050

P-1411• 819-0361

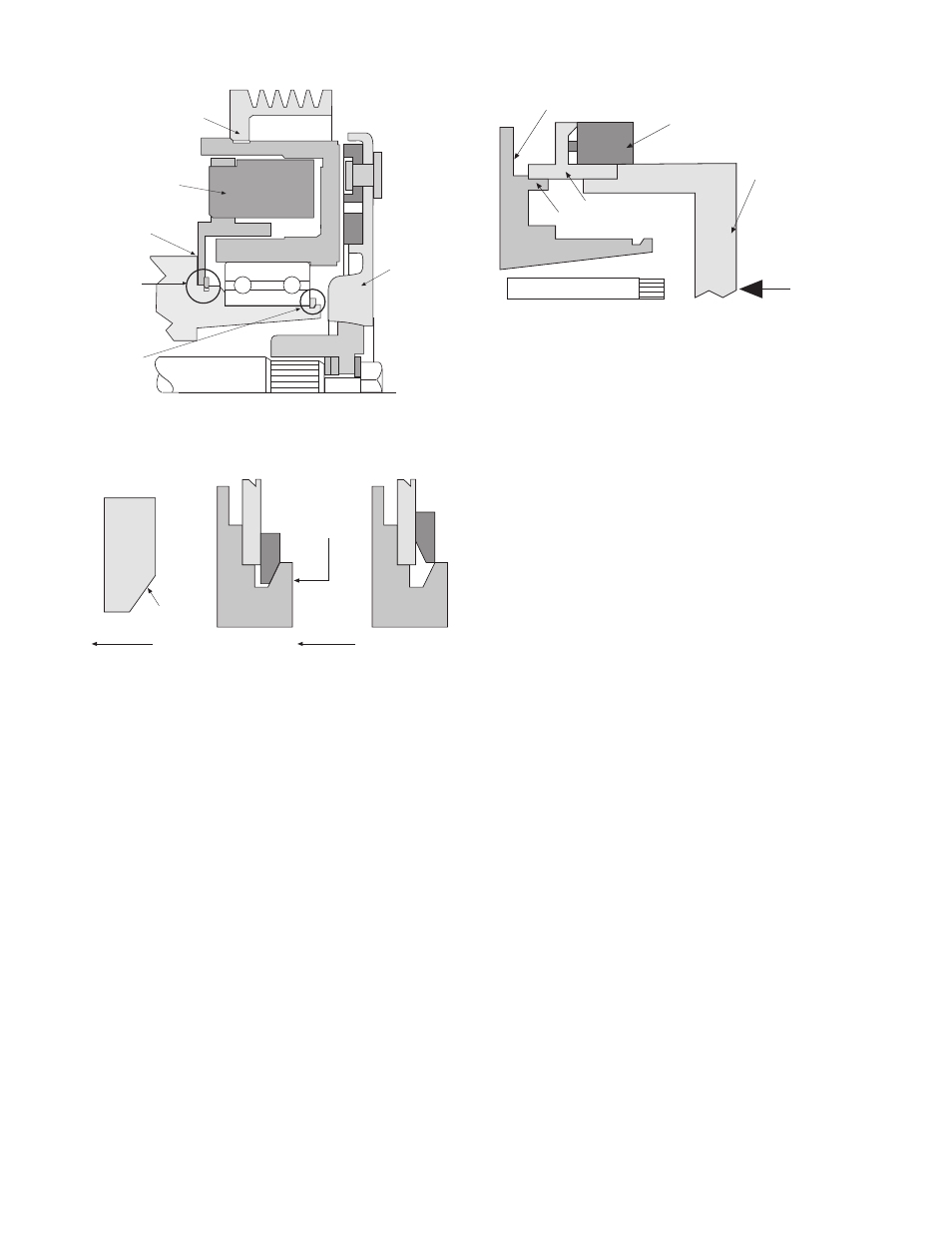

(Figure 2) Location of Clutch Snap Rings

C. Verify that the snap ring is fully seated in the

groove around its circumference to assure

assembly retention. (See Figure 4)

D. Attach ground lead, if used, to the compres-

sor housing and tighten screw.

E. Proceed to Step 3.

Fully seated

snap ring

Bevel

Compressor

Install with beveled face away from compressor

Snap Rings

Compressor

Correct

Incorrect

(Figure 3)

Snap Ring

Bevel

(Figure 4)

Correct and Incorrect

Installation

Field Assembly

Compressor Pilot for

Field Coil Assembly

Compressor Shaft

Compressor Shoulder

Do Not press

on Plastic Coil

body

Press

Direction

Insert field

installation tool

into inside diameter

of assembly

(Figure 5) Ford FX-15 & FS-10 Field Installation

Step 2B. Installing the Field Coil (12) for all

Ford FX-15 & FS-10 fields

A. Stand the compressor on end with the nose

pointing up. Position the field assembly (12)

such that the field shell starts to overlap the

compressor nose field mounting surface.

Ensure the electrical connector aligns with

original connector position before continuing.

B. Insert the field installation tool into the inside

diameter of the shell. (See Figure 5)

C. Visually check to ensure the field is positioned

squarely. Press the field assembly onto the field

mounting surface until it bottoms on the com-

pressor shoulder.

Unidamp®

Armature

Assembly

Rotor/Pulley

Assembly

Field

Assembly

Compressor

Field Coil

Assembly

Snap Ring

Rotor/Pulley

Assembly

Snap Ring