Warner Electric Compressor Clutch Replacement Procedure User Manual

Page 2

2

Warner Electric • 800-825-9050

P-1411• 819-0361

Keep fingers, hands and other

body parts and loose clothing away from

rotating components.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Compressor Clutch Removal

Note: Do not pound on the clutch, compressor

or Unidamp as damage will result to

components.

Step 1. Diagnose Clutch Failure

Most compressor clutch failures are a direct

result of items external to the clutch. These can

include compressor failure, electrical problems,

or oil contamination.

Before installing a new

clutch, determine what caused the old clutch

to fail and fix the problem.

If the clutch is replaced without fixing the cause

of the clutch failure, the new clutch may fail in

the same manner as the old clutch.

Please refer to Warner Electric's “Air

Conditioning Clutch Troubleshooting Guide,”

form number P-1011, and the appropriate

manufacturer's A/C service manuals.

Step 2. Removing Hub/Armature Assembly (3)

A. Remove shaft bolt (6).

B. Remove washer (5).

C. Remove hub/armature (3) by hand. World

Clutch has an 8mm threaded hole to use as a

jack screw for removal.

D. Remove shims (4) from the hub/armature

assembly. The number of shims can vary.

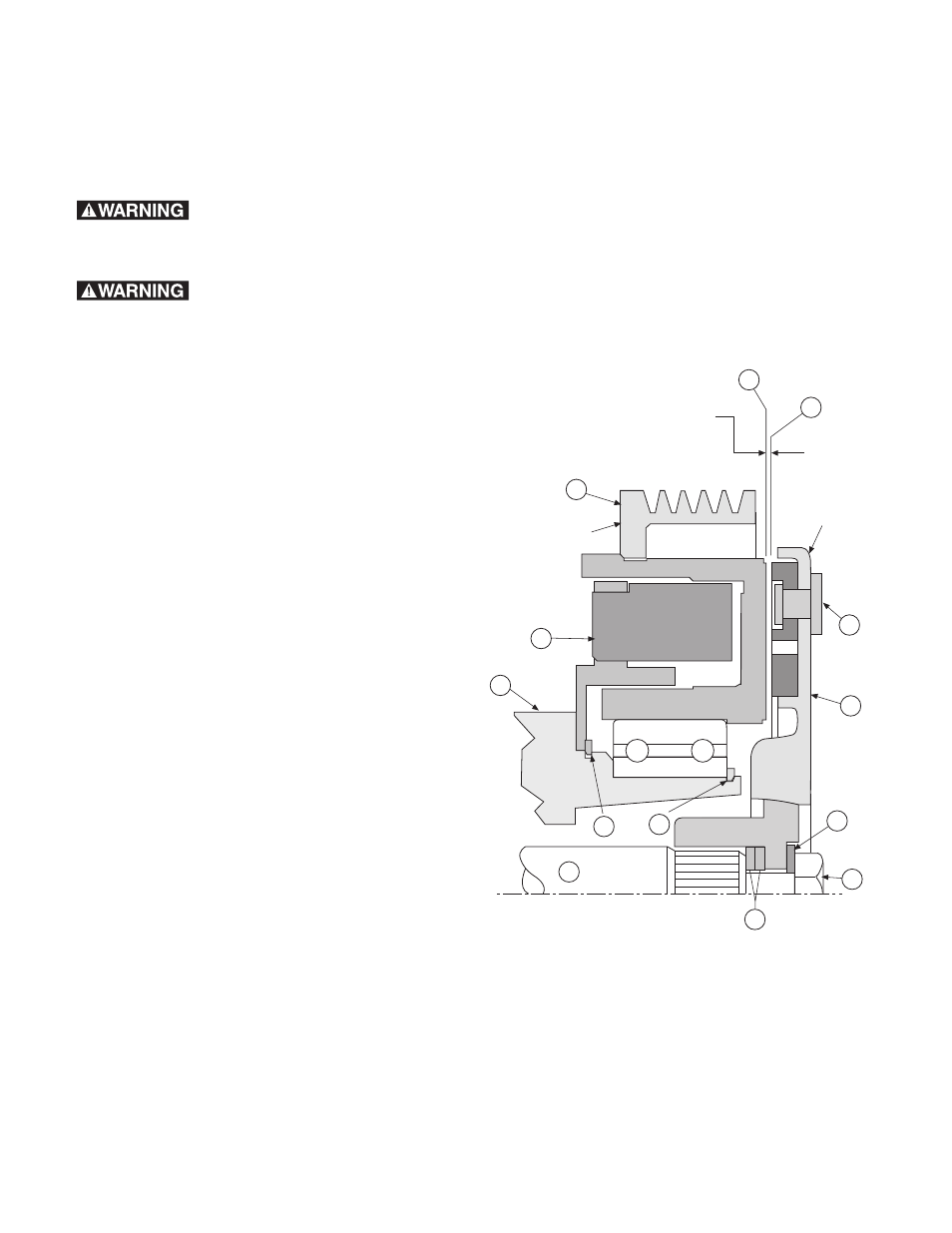

Unidamp

®

Hub/Armature

Assembly

Field/Coil

Assembly

Rotor/Pulley

Assembly

12

13

4

6

5

3

7

8

1

2

Rotor/Pulley to

Hub/Armature airgap

0.018" to 0.030" new part

0.013" to 0.025" used part

(measured 120˚ apart)

11

9

10

(Figure 1) Clutch Components

World Clutch with Unidamp

®

Armature Assembly for Ford FX-15

and FS-10 Compressors and all

Denso Models with 30mm bearing fit.