Warner Electric L Series 310 User Manual

Page 5

Warner Electric Europe • +33 (0)2 41 21 24 24

P-2072-WE • 2/13 5

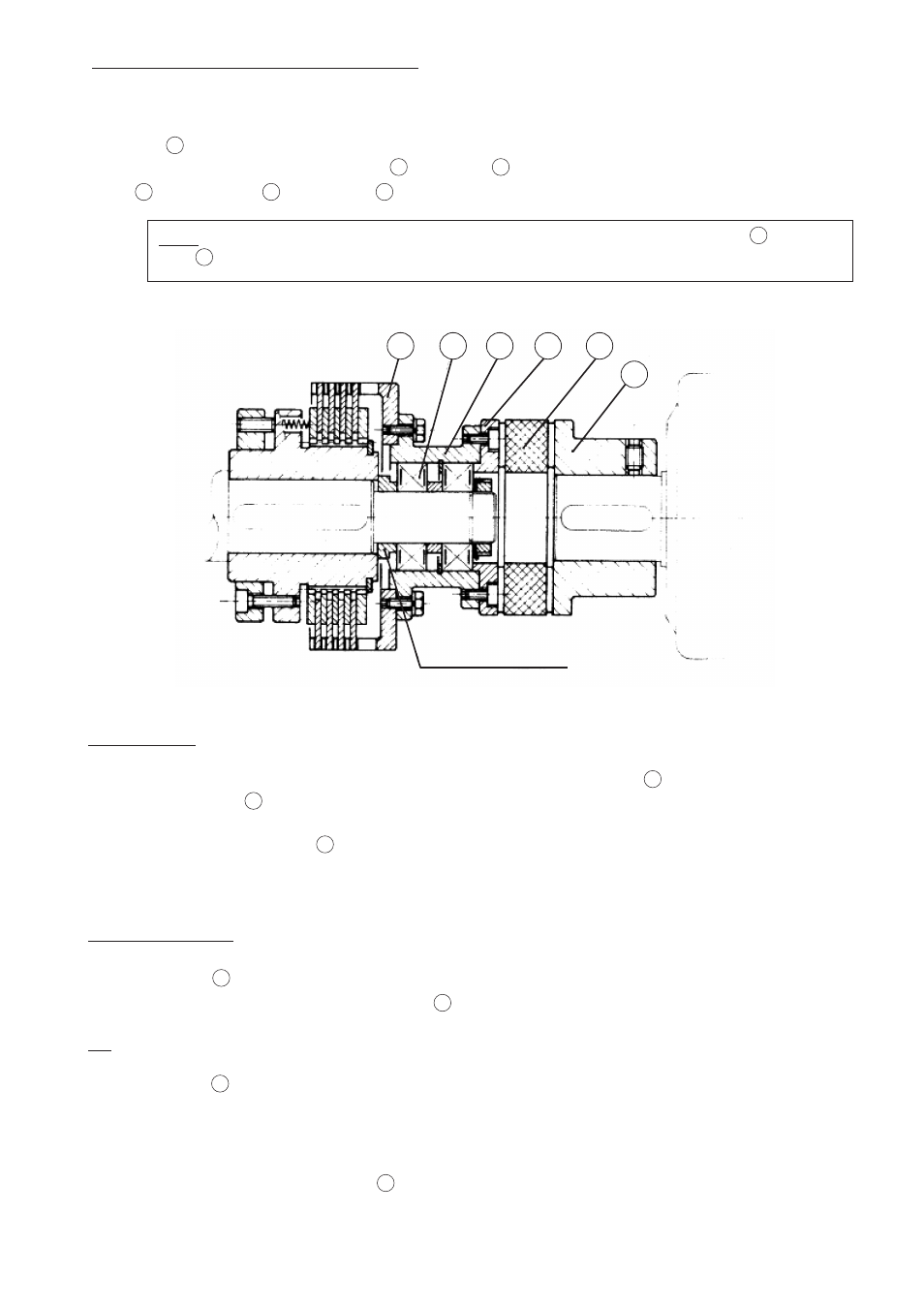

3.3 - Fitting with elastic coupling : L series 110.05

This fitting method ensures a perfect alignment of both sides of the torque-limiter when coupling two shaft-ends.

The spider

11

is centered and fitted on the shaft-end on which the other side of the unit is assembled (see

chapter 3.1) by means of two ball-bearings

13

and a case

14

bound to the elastic coupling, which consists of a

flange

15

, a toothed ring

16

and a sleeve

17

.

Note: After the unit has been fitted on the shaft, the screws used to fasten the flange

15

onto the

case

14

will have to be secured by the customer with LOCTITE - 270

4

ADJUSTMENT

The limiter is adjusted to be calibrated torque by acting on the adjusting screws

9

after unscrewing the wear

compensation screws

10

:

• Screwing the adjusting screws

9

(clockwise) increases the torque.

• Unscrewing them (anti-clockwise) reduces it.

Proceed as follows:

• Lock the spider

11

• Measure the static or slipping torque of the hub

1

by means of a torque wrench.

Or:

• Submit the hub

1

to a torque (by using a lever arm for example) :

• Measure this torque with a pair of scales or with a mass equal to the torque to be limited and placed at the end

of a one-meter long lever arm.

• Check dimensions “Z” in several places : it should be the same for all.

• Tighten the wear compensation screws

10

after adjusting the torque.

11

13

14

15

16

17

Distance - piéce