Warner Electric Preassembled Clutch_Electrically Released Brake Module User Manual

Page 3

Warner Electric • 800-825-9050

819-0346 • P-273-2 3

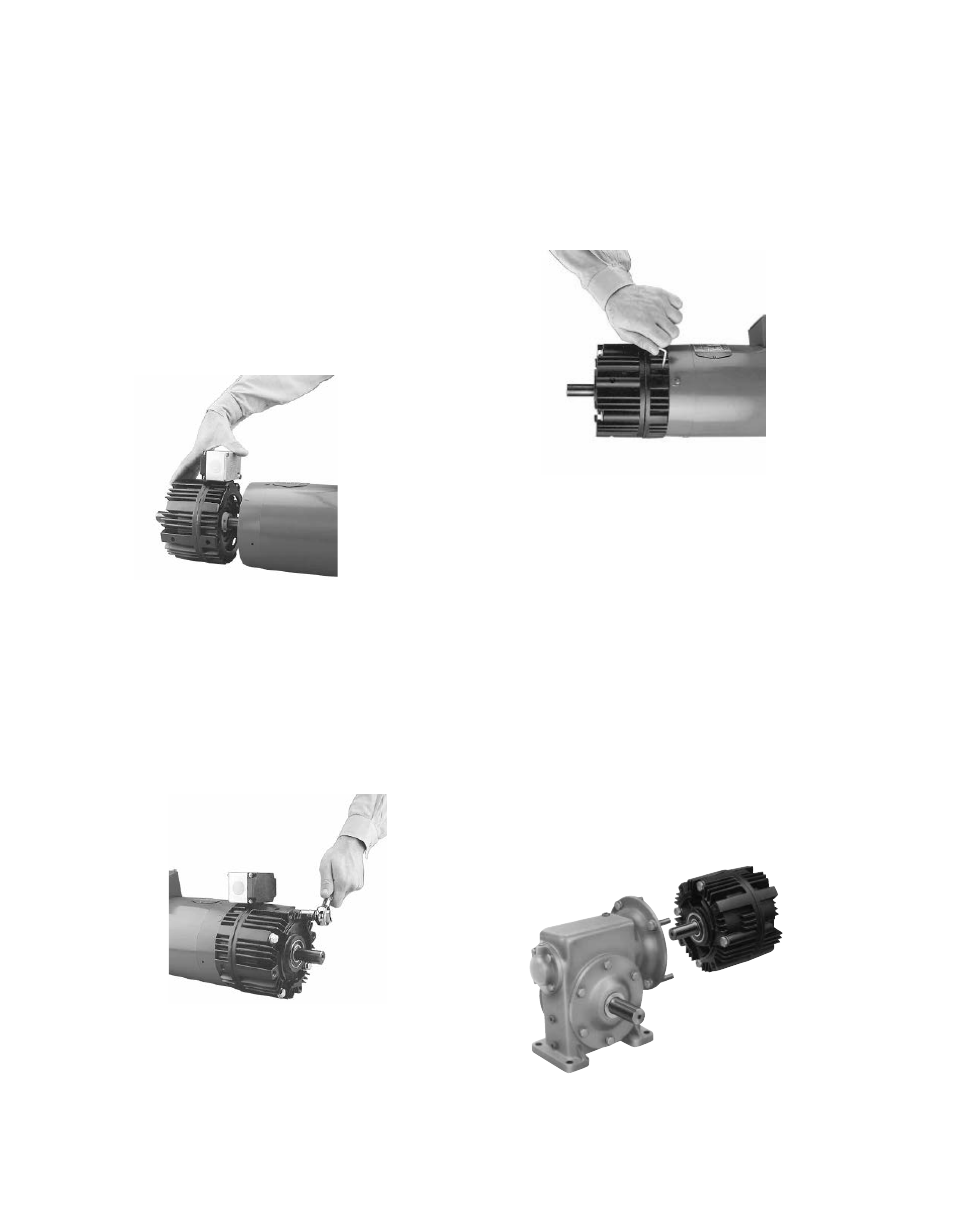

Mounting to a Motor

1. Replace the existing motor shaft key with

the hardened key provided with the unit. If

necessary, prick punch the keyway of the

motor shaft to keep the key from moving in the

keyway. Slide the module assembly onto the

motor shaft. (See Figure 1) Align the key in the

motor shaft with the keyway in the rotor hub.

Do not use force. If the UniModule does

not slide on freely, polish the motor shaft

sufficiently to achieve a slip fit.

Figure 1

2. The housing is provided with vent holes

which are normally placed in the down posi-

tion . Rotate the assembly to where the vent

holes are toward the bottom and insert the

four long capscrews (provided) through the

mounting holes in the housing and into the

motor face. Tighten alternately and securely.

(30 to 35 ft. lbs.)

Figure 2

3. The access hole for the Allen wrench to tight-

en the rotor setscrews is shown in Figure 3 .

Rotate the clutch rotor as necessary to insert

the wrench into the setscrews . Tighten both

screws alternately and securely. (40 to 45 in.

lbs. for 180 size, 80 to 85 in. lbs. for 50 and

210 sizes.)

Mounting to a Reducer

The output side of a Unimodule may be mounted

directly to a reducer .

A. Align the output shaft and key of the

Unimodule with the corresponding shaft hole

and keyway of the reducer. Slide the assembly

together, matching the pilot diameter on

the Unimodule with a pilot diameter on the

reducer .

B. Bolt the Unimodule to the reducer flange. The

four (4) bolts required (3/8-16 UNC-2A) are

normally furnished with the reducer. (18 to 22

ft. lbs. for 50 and 180 sizes, 40 to 45 lbs. for

210 size.)

Figure 4

Figure 3