Warner Electric ERS Electrically Released Brakes User Manual

Page 3

3

Warner Electric • 800-825-9050

819-0337

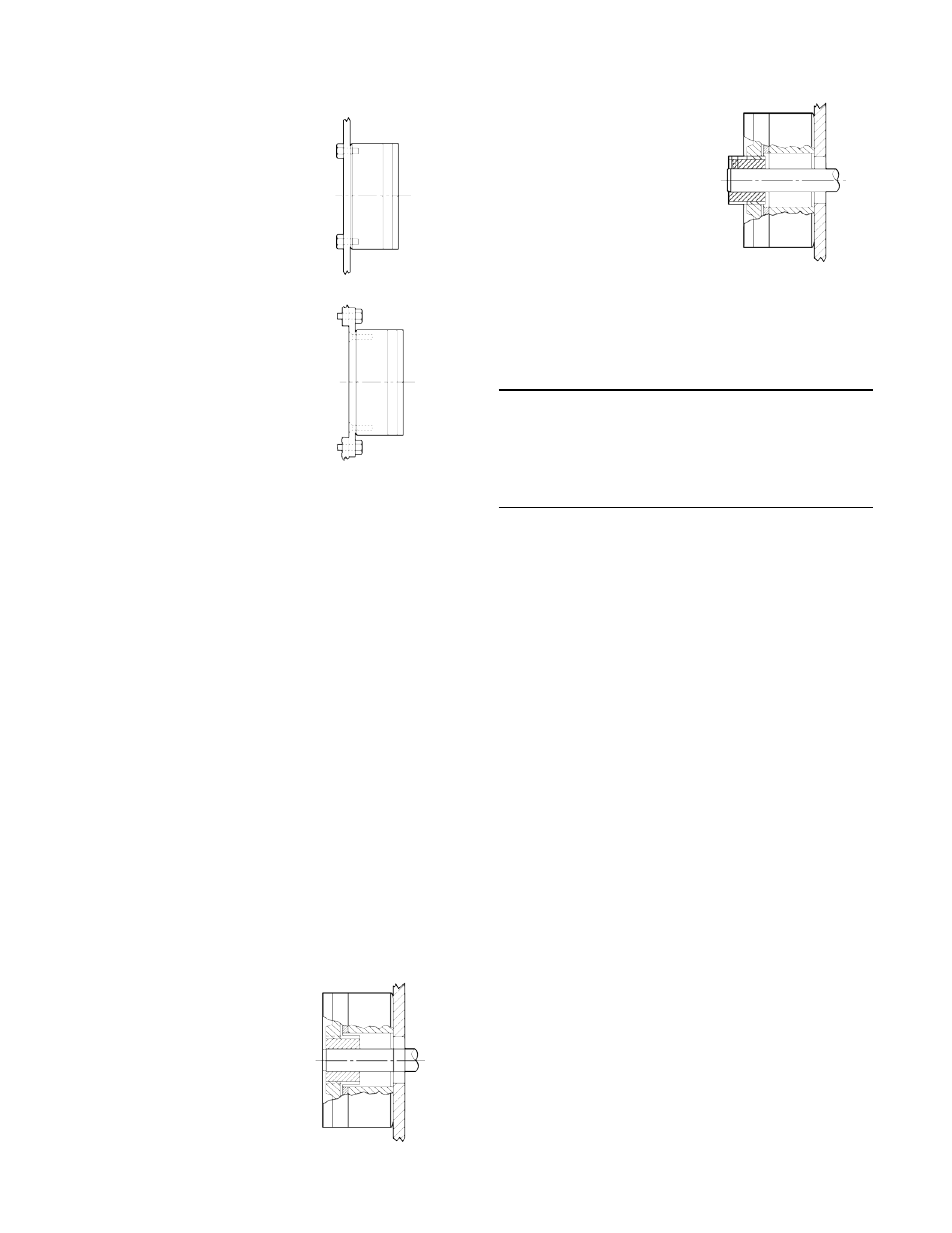

Tapped Holes

Mounting the brake by

drawing it into a housing or

cavity again provides the rigid

support in an area no larger

than the outside diameter of

the brake. It is used where

through-bolt mounting is

impractical.

Flange

Mounting flanges can be

attached to the base design

using the tapped holes

provided.

Since the mating spline (either the Warner

Electric splined hub or your splined shaft) is

smaller than the brake bore, either end of the

brake can be positioned against the mounting

surface when using through bolts. If a Warner

Electric conduit box is being used and the back

of the brake must be against the mounting

surface, a relief in the mounting surface will be

required to accommodate the conduit box

mounting plate. (See page 4 for details).

Hub Mounting Options

If the Warner Electric splined drive hub is to be

used, it can be mounted in either of the

following sequences:

Note: Full spline engagement contact is

required between the splined hub or splined

shaft and the splined brake disc. The disc

must be able to move freely on the hub.

Recessed Hub

Mounting the hub on the

driving member prior to

mounting the brake

allows the splined hub to

be recessed in the brake

bore for maximum space

efficiency.

Extended Hub

Mounting the hub on the

driving member after

mounting the brake allows

the splined hub to extend

beyond the brake where

space allows.

When the splined hub has been located on the

shaft with its appropriate key, tighten the set

screws to the following torque values:

Brake

Torque

ERS-26

10 lb. in.

ERS-42

20 lb. in.

ERS-49

35 lb. in.

ERS-57

35 lb. in.

ERS-68

85 lb. in.

Loc-tite

®

242 may be applied on screw threads

to minimize chances of screws backing off

under severe vibration.

4. After the brake and hub are secured in place,

attach the DC power source to the brake

terminals. Feed the wires through the brake

insulator boots before attaching them. After

the terminal screws are tightened (torque to

15 lb. in.), slide the boots over the screws

and terminals to insulate the electrical

connection.

Either terminal can be connected to the + or -

side of the power source. If a Warner Electric

CBC-100 or other Warner Electric control is

used, follow the wiring instructions supplied

with the control.

5. Your ERS brake is now ready for its static

test. Apply the rated DC voltage to the brake.

It should disengage and the shaft should

rotate freely.

Your ERS Brake is now ready to run.