Torque adjustments, Friction disc replacement, Magnetic coil replacement – Warner Electric UNIBRAKE User Manual

Page 5

5

Warner Electric • 800-825-9050

P-1699-WE

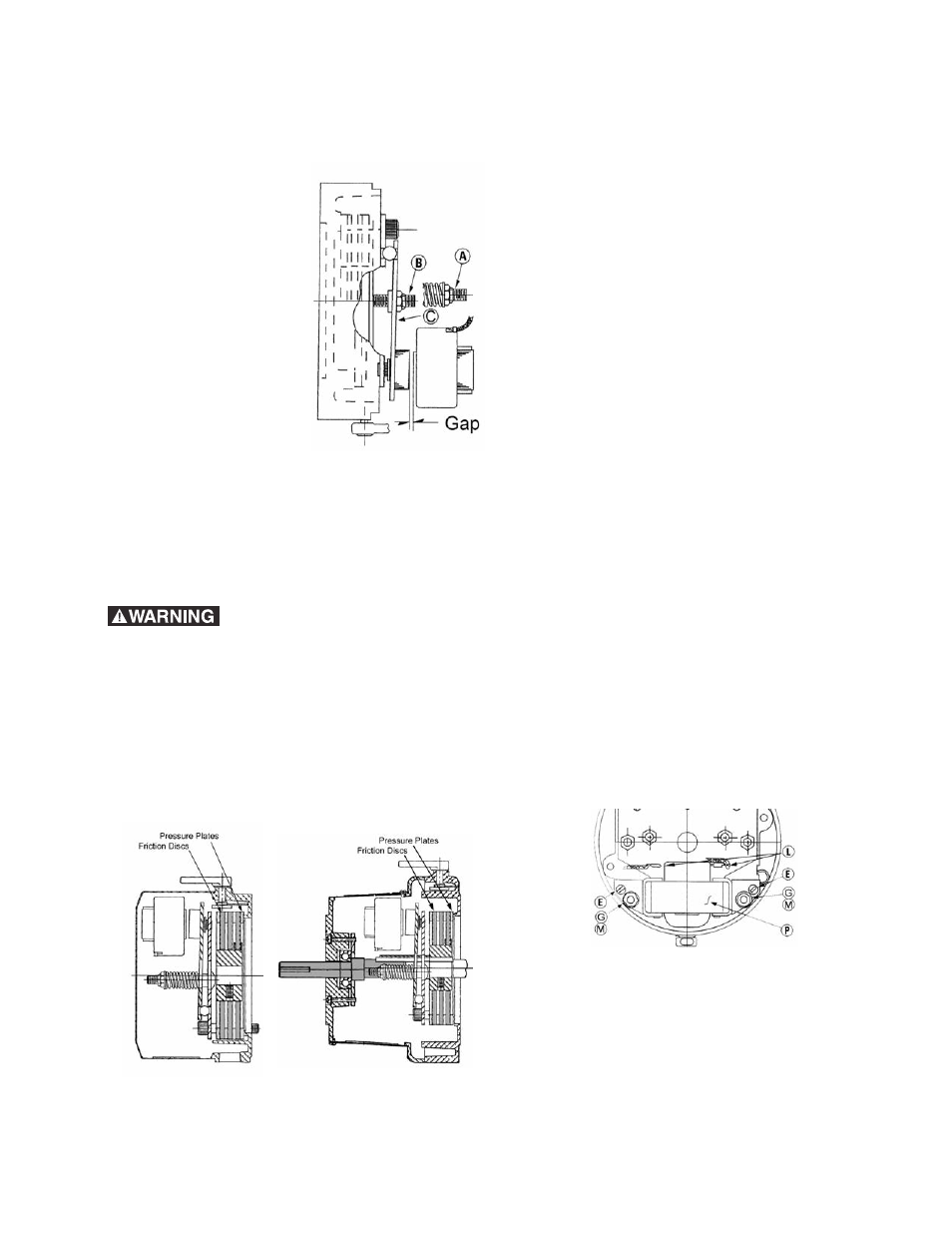

Torque Adjustments

Most applications do not require torque

adjustments. Unibrakes

are factory set for rated

torque which is maximum

torque. To increase

stopping time or reduce

torque on 3, 6, and 10 ft.

lb., turn 2 lock nuts “A” an

equal amount counter-

clockwise to increase

spring length. For the 6,

10, and 15 ft. lb. brakes,

one full turn will reduce

torque by about 12-1/2%.

The 3 ft. lb. brake will be

reduced in torque by about 8%. Torque should not

be reduced by less than 1/2 of the rated torque.

If torque is adjusted, measure air gap (see wear

adjustment) and verify it is within dimensions from

Gap Chart.

1) Disconnect power brake

before touching any internal part. 2) Any loads

that are held in position by this brake must be

supported before performing any adjustments

or maintenance.

Friction Disc Replacement

Rear Mounted Coupler

Rear Mounted

Remove cover, (2) cover support studs “G”, and (2)

3/8-16 mounting cap screws at “M”.

Lift off brake mechanism assembly. Remove

pressure plate(s) and brake disc(s). Replace with

new pressure plate(s) and disc(s). Reassemble

brake mechanism assembly. Multiple disc units,

the domed pressure plate is positioned furthest

away from the motor or brake head; the (B) wear

adjustment screws are in contact with this plate.

Note: Cast Iron Heads: Last disc uses the cast

housing as a friction surface. Set air gap for wear

adjustment.

Coupler

Remove (4) hex head screws that hold the

cover/shaft assembly to the brake head. Remove

the (4) 3/8-16 mounting cap screws at “M.”

Remove (2) 1/4-20 round head screws and lift off

brake mechanism assembly. Remove pressure

plate(s) and brake disc(s). Replace with new

pressure plate(s) and disc(s). Reassemble brake

mechanism assembly. Multiple disc units, the

domed pressure plate is positioned furthest away

from the motor or brake head; the (B) wear

adjustment screws are in contact with this plate.

Set air gap for wear adjustment.

Magnetic Coil Replacement

Rear Mounted

Remove cover, (1) cover support stud “G”, (1)

3/8-16 mounting cap screw “M” and (2) slotted

screws “E”.