Wiring, Wear adjustments – Warner Electric UNIBRAKE User Manual

Page 4

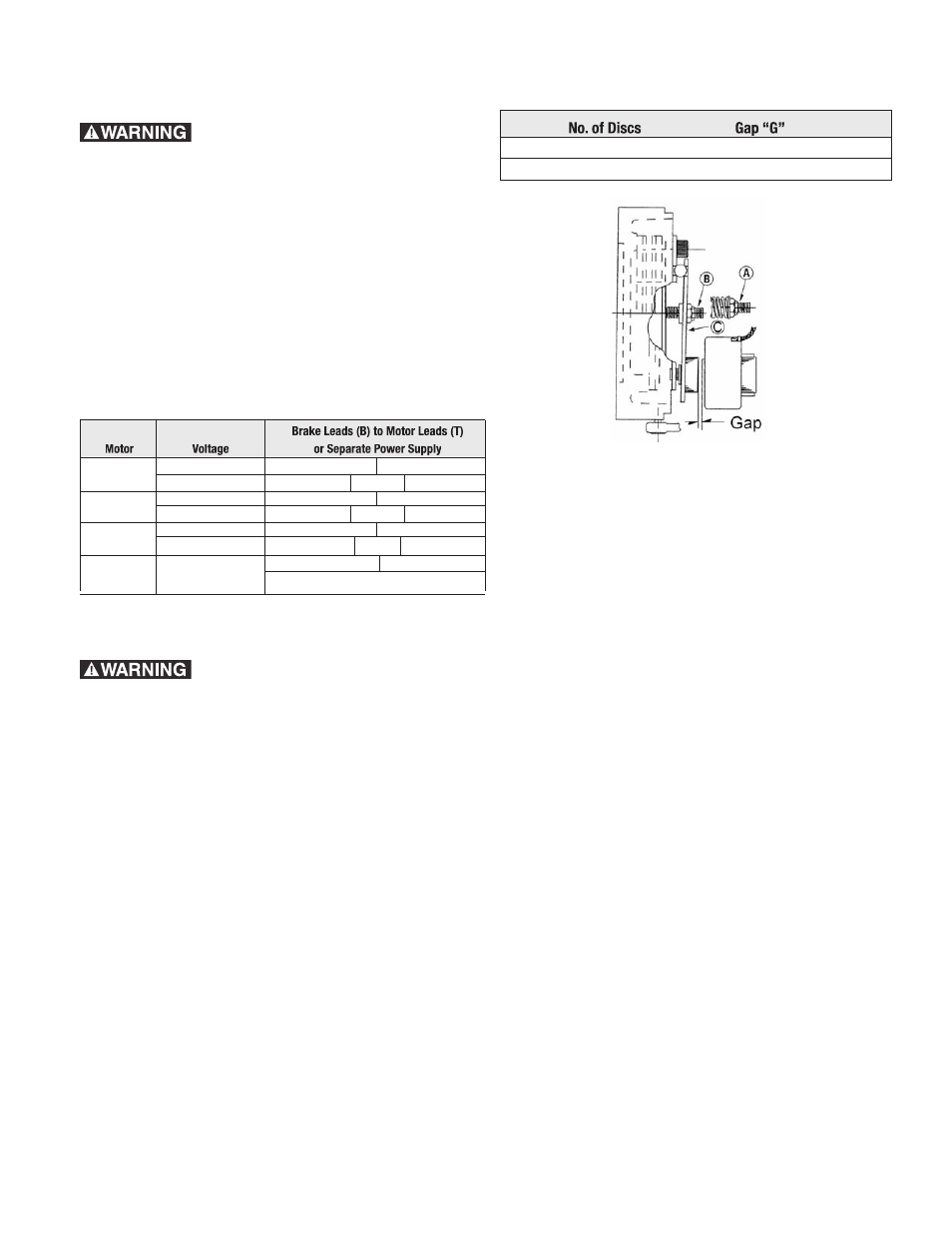

Gap Chart

No. of Discs

Gap “G”

1

.075 inch

2 or 3

.090 inch

Rear Mounted

Remove cover; turn both screws “B” equal

amounts in a clockwise direction until air gap (Gap

“G”) from above chart is obtained. Measurement

of air gap should be made at approximate center

of magnet with pressure applied to armature plate

“C” to assure plate is seated on pivot balls. Failure

to adjust for wear will result in eventual loss of

braking torque.

Note: Unequal adjustment of screws “B” will result

in unequal pivot action on balls that will increase

noise and shorten brake life.

Coupler

Remove the 3 window covers, turn both screws

“B” equal amounts in a clockwise direction until air

gap (Gap “G”) from above chart is obtained.

Measurement of air gap should be made at

approximate center of magnet with pressure

applied to armature plate “C” to assure plate is

seated on pivot balls. Failure to adjust for wear will

result in eventual loss of braking torque.

Note: Unequal adjustment of screws (B) will result

in unequal pivot action on balls that will increase

noise and shorten brake life.

4

Warner Electric • 800-825-9050

P-1699-WE

Wiring

Disconnect power before

touching any internal part.

Unibrake magnet coils (AC) are single phase and

dual voltage. These can be wired internal to the

motor. Direct current brake coils must be

separately operated; switch contacts to control the

brake must be different from those used to control

the motor. Normally, motor and brake

contacts must be interlocked.

Determine the voltage of the brake and use the

appropriate wiring instructions below.

Wear Adjustments

1) Disconnect power brake before

touching any internal part. 2) Any loads that are

held in position by this brake must be

supported before performing any adjustments

or maintenance.

Unibrake discs require periodic adjustment due to

expected wear. On rapid cycling applications

regular inspections should take place, i.e. after

20,000 to 50,000 cycles for the first inspection and

then every 150,000 to 200,000 cycles. Adjustments

should be made to the air gap between the

armature and magnet for continued brake

effectiveness. If an increase in stopping time is

noted adjust brake as follows:

Brake Leads (B) to Motor Leads (T)

Motor

Voltage

or Separate Power Supply

3 Phase AC

Low Voltage

B1 & B3 to T1 & T7 B2 & B4 to T2 & T8

High Voltage

B1 to T1 B2 to B3 B4 to T2

1 Phase AC

Low Voltage

B1 & B3 to T1 & T3 B2 & B4 to T2 & T4

High Voltage

B1 to T1 B2 to B3 B4 to T4

Separately AC

Low Voltage

B1 & B3 to Line 1 (L1) B2 & B4 to Line 2 (L2)

High Voltage

B1 to Line 1 (L1) B2 to B3 B4 to Line 2 (L2)

Separately DC

24 or 90 VDC

B1 to DC + B2 to DC -

Coils are not polarity sensitive

connections can be reversed.