Coupler, Installation, Rear mounted – Warner Electric UNIBRAKE User Manual

Page 3

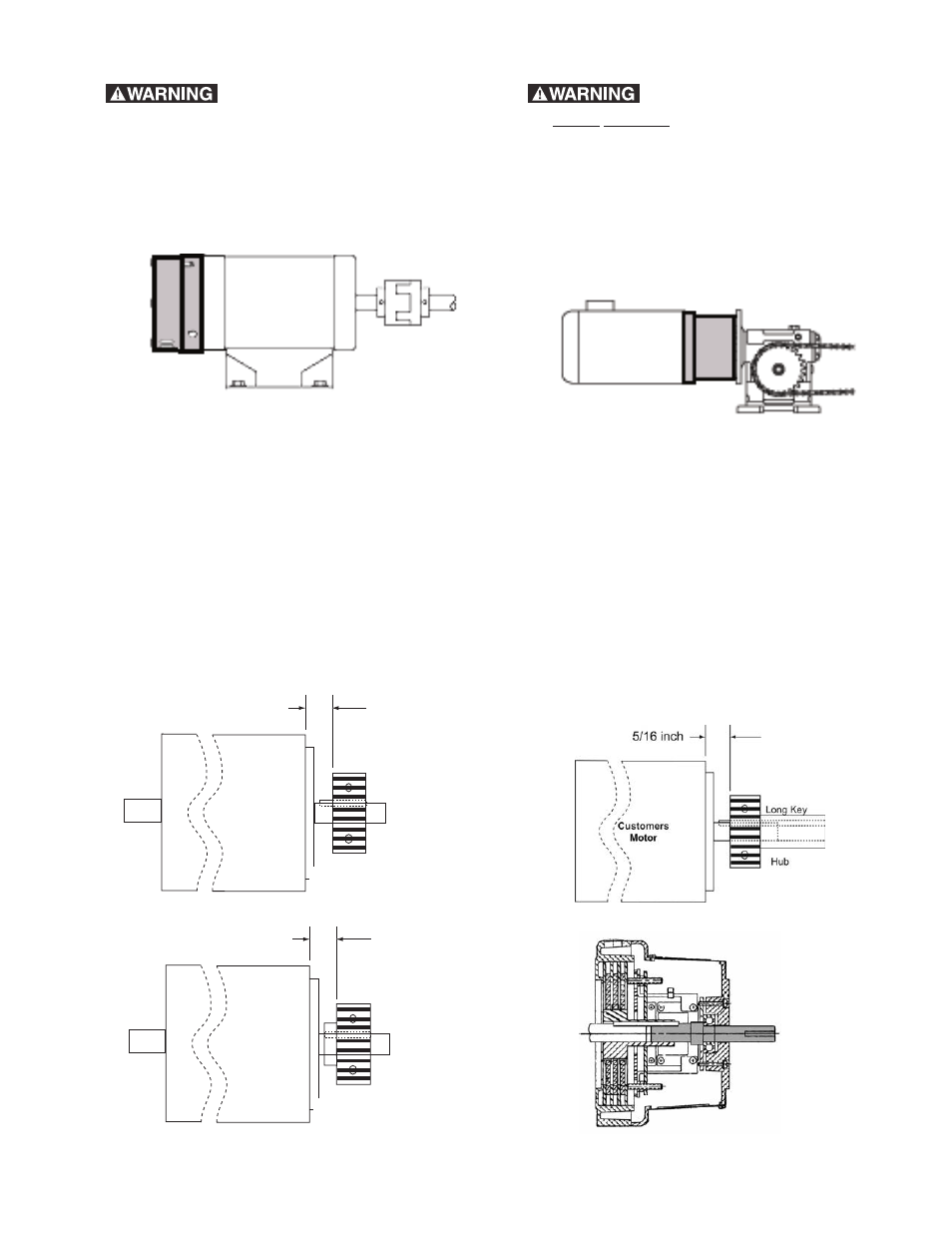

Coupler style output shaft must

be direct coupled to load not for belted or any

type overhung load applications.

Remove (4) hex screws and lift off cover/shaft

assembly. Remove brake hub and attach it to the

motor shaft using the long key and set screws.

Locate hub 5/16 inch away from mounting face of

motor as shown below. Tighten setscrews to 55-

100 in. lbs. of torque. Slip brake head assembly

over brake hub and onto the motor mounting face.

Fasten with (4) 3/8-16 socket head cap screws.

Leads should be twisted and routed across top

front of coil away from rotating brake hub and then

routed through lead clip on side of coil. Replace

brake cover/shaft assembly after wiring by

inserting keyed shaft into the brake hub extension

and guiding cover over the brake head assembly,

the center window should be located over brake

release lever to allow for gap inspection. Secure

with (4) hex bolts and nuts.

Coupler

3

Warner Electric • 800-825-9050

P-1699-WE

Any mechanism or load held in

position by the brake should be checked to

avoid possible damage or injury to personnel

before brake is released manually.

Installation

Remove cover from brake, locate brake hub. At-

tach hub to shaft using key and set screw

provided. Position hub from mounting face of motor

as shown for your type of brake head. Tighten set

screws to 55-100 in. lbs. of torque. Slip brake head

body onto mounting face and fasten with (2) 3/8

inch socket head cap screws. Cover will be assem-

bled after brake is wired. Leads should be twisted

and inserted into the insulation sleeve and routed

to conduit port or openings through back of motor.

Rear

Mounted

Rear Mounted

Coupler

Customers

Motor

5/16 inch

Hub

Key

Motor

Output

Shaft

End

Customers

Motor

Hub

Key

Motor

Output

Shaft

End

1/2 inch

Aluminum Brake Head

Cast Iron Brake Head