Pipe overview, Fittings – System Sensor Pipe Installation User Manual

Page 4

User Guide: Aspirating Smoke Detector Pipe Installation

4

Pipe Overview

Pipe Network Components

The FAAST detector uses standard aspiration fire detection pipe

network components, such as pipes, elbows and couplings.

The components listed in this section are not an all inclusive list,

however they represent the most commonly used items.

Pipes

The pipes used in the pipe network can be made of various

materials including copper, PVC, ABS, UPVC and CPVC. The

internal pipe diameter used with the FAAST system can range

from 0.591" to 0.827" (15 to 21 mm). Ideal dimensions vary

depending on system design requirements as well as local

codes and regulations. The FAAST detector has a built in tiered

insertion point for the pipes which allows for an outside tube

diameter of either 1.050" or 25 mm to accommodate U.S.

Customary System and Metric System Sized Pipes.

Frequently Asked Question – Can we use metal pipe instead

of plastic with FAAST?

Yes. It is acceptable to use either steel or copper pipe under the

following conditions:

• The pipe size used must be capable of fitting to a plastic

pipe upon interfacing with the FAAST device. The inner

diameter must be within the approved range of

.591" - .827" ( 15.00 - 21.00 mm ).

• The material must be approved by the local authority

having jurisdiction and must also be approved by the

insurance underwriter

Pipe Temperature

Pipe selection may be contingent on the temperature of the

room in which the pipe will be mounted. Table 1 shows

temperature ranges for various types of pipe.

Pipe Material

Service Temperature

ABS

-40 – 80°C (-40 to 176°F)

PE-80

-50 to 60°C (-58 to 140°F)

PE-100

-50 to 60°C (-58 to 140°F)

CPVC

-26 to 93°C (-15 to 200°F )

PVC

-26 to 49°C (-15 to 120°F)

Copper

-150 to 110°C (-238 to 230°F)

Table 1: Temperature ranges for various types of pipe.

* For specific design considerations in cold temperature

applications, download the Cold Storage White Paper from

systemsensor.com/faast

Fittings

Fittings are used to connect sections of pipe together on longer

network runs and are made from the same material as the pipe.

There are several types of fittings to allow for various bends,

straight runs, branches and connections. Common fittings are

described in the following sections.

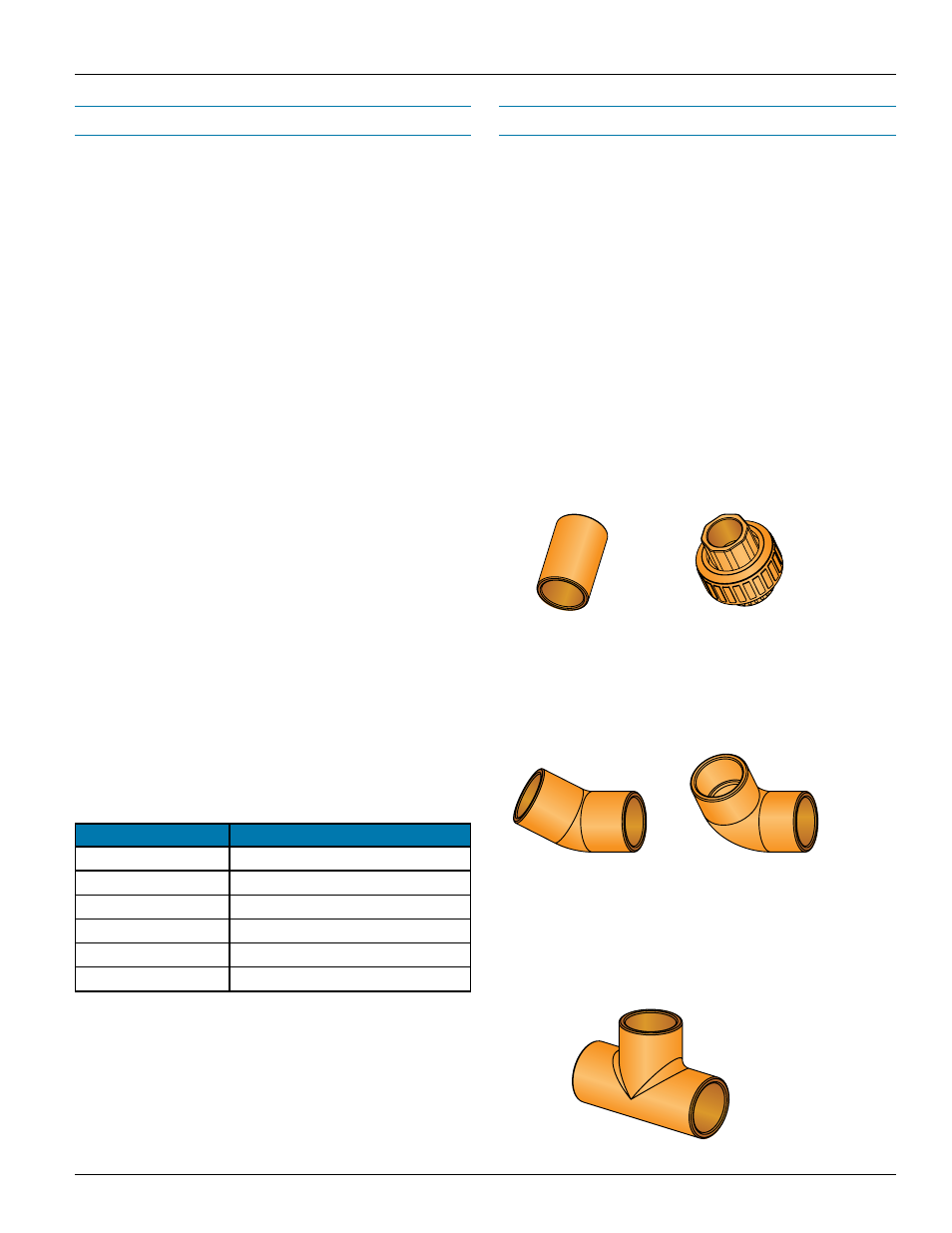

Couplings and Unions

Couplings and unions are used to connect two sections of pipe

in a straight line. A coupling is used when the section is not

intended to be taken apart.

A union offers the ability to screw the two pipe sections together

for future access, such as areas of the pipe network that have

to be periodically disassembled for maintenance and cleaning.

Unions can also be used to orient sample ports correctly in

a specific section of the pipe network, such as over return

air grilles (for more information on high air flow and duct

applications, see the white paper at systemsensor.com/faast).

Figure 1 shows a typical union and coupling.

ASP-76

ASP-75

Figure 1: Couplings and unions.

Elbows

Elbows are used to change the direction of the pipe network.

Both 45 degree and 90 degree elbows may be used. Both

elbow fittings are shown in figure 2.

45°

ASP-77

ASP-78

90°

Figure 2: Elbows.

Tees

Tees are also used for branching into multiple pipes from a

single pipe network. A specialized tee can be used to attach a

capillary tube and a sampling port. A tee is shown in figure 3.

ASP-80

Figure 3: Tees