Under floor protection, Inter-beam / below-beam sampling, Floor void sampling – System Sensor Pipe Installation User Manual

Page 13: Floor void test sample port

User Guide: Aspirating Smoke Detector Pipe Installation

13

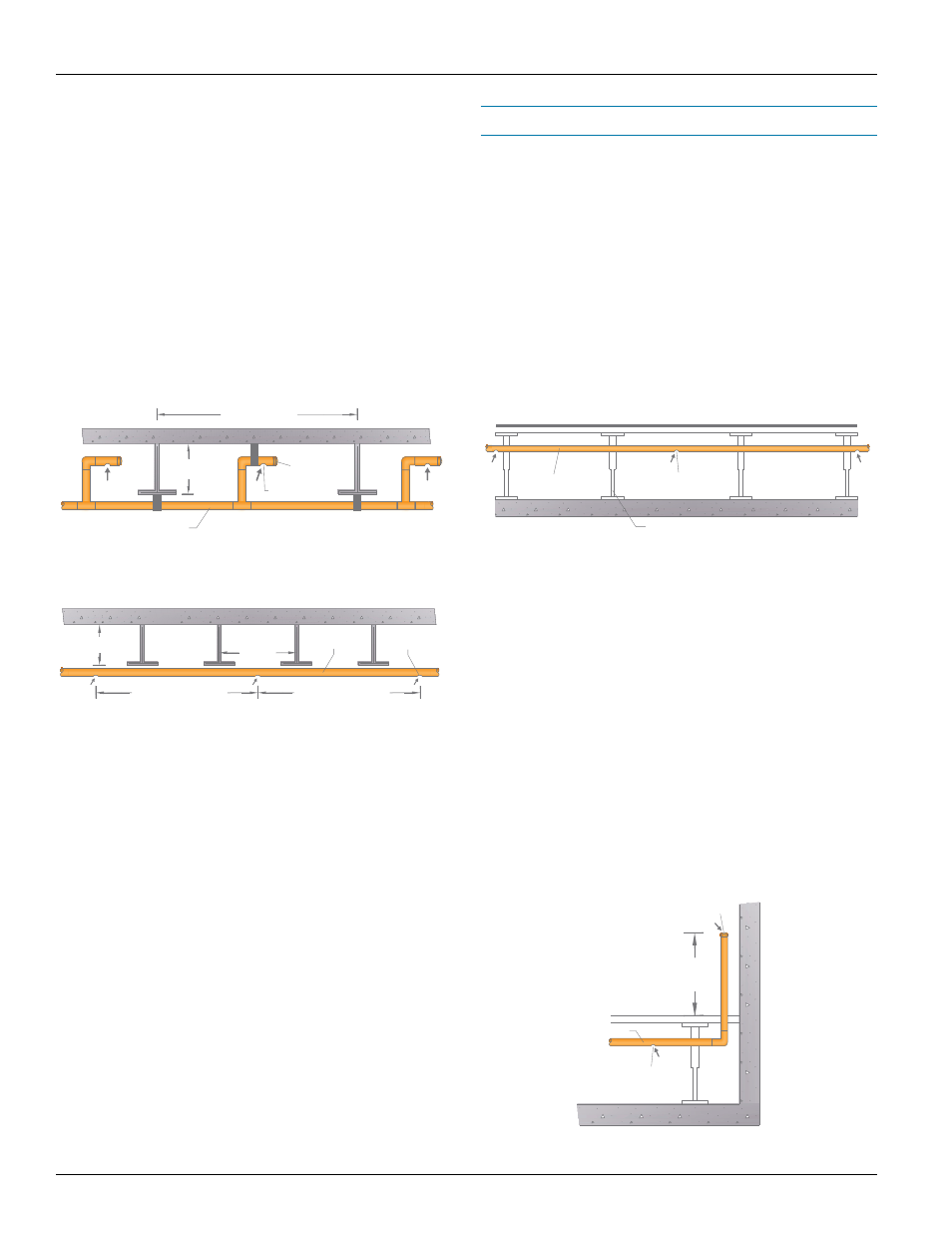

Inter-Beam / Below-Beam Sampling

When large ceiling beams are used in construction, pockets of

space are created between the beams. In normal circumstanc-

es, the pipe network is mounted on the bottom of the beams

and does not sample the large space between the beams. If it

is necessary to cover this space, a rigid pipe in the shape of an

inverted “L” can be extended vertically from the pipe network

up into the area between the beams so that the pipe reaches up

towards the ceiling in these locations. The sampling port should

be drilled just before the end cap on the horizontal portion of the

pipe. The ends of these sampling pipes should be capped with

an end cap, which may or may not have a sample port based

on the pipe network design.

Frequently Asked Question – How do I know if the beam

pocket has to be protected?

In exposed beam construction the sample port shall be spaced

based on the requirements of NFPA 72®. If the beam depth is

equal to or greater than 10% of the ceiling height and beam

spacing is greater than or equal to 40% of the ceiling height,

than detection shall be provided in each beam pocket per NFPA

72®. For beams with less than 10% of ceiling height, smooth

ceiling spacing shall be permitted.

Under Floor Protection

Floor Void Sampling

The FAAST system is well suited to protect concealed voids,

either in the ceiling or under the floor. Some locations use either

ceiling and/or under floor voids as return air plenums (ducts).

A pipe network must be designed to monitor the flow of return

air through these areas. Some ceiling and floor voids are used

for cable runs or for small equipment installation. Monitoring of

these areas must be done using a pipe network designed for

operation in these areas. When installing pipe in a floor void,

keep in mind that the air sampling ports are still located at

the bottom of the pipe. This means the pipe would be located

towards the upper portion of the void.

Frequently Asked Question – Can I monitor the ceiling and

under the floor with one detector?

FAAST can monitor two areas with one detector, however,

it is not recommended practice due to pressure differentials.

Areas with pressure difference of +/- 20% delta of one another

can create air flow faults. Therefore it is recommended to

provide each area with its own detector.

Floor Void Test Sample Port

It is recommended to install a test sample port when designing

an under floor system. A test sample port will allow an easier

commissioning process without disrupting the floor operation.

It is recommended to locate the test port at the end of each

branch pipe at a minimum of 18 in. above the raised floor. The

port diameter should be determined and verified by using the

PipeIQ Software.

Sampling Pipe

Sampling Port

End cap

Beam Pocket

+40% (0.4H)

+10% (0.1H)

Figure 14: Inter-beam sampling.

Figure 15: Below-beam sampling.

Figure 16: Floor void sampling.

Figure 17: Floor void test sample port location.

Sampling Pipe

Floor

Ground

Floor Supports

Floor Void

Sampling Port

Sampling Pipe

Floor

Sampling Port

18 in.

(450 mm)

End cap with

Sample Test Port

Sampling Pipe

Sampling Port

MAX SPACING

MAX SPACING

N/A

-10% (0.1H)