Large area protection, Cold area protection – System Sensor Pipe Installation User Manual

Page 15

User Guide: Aspirating Smoke Detector Pipe Installation

15

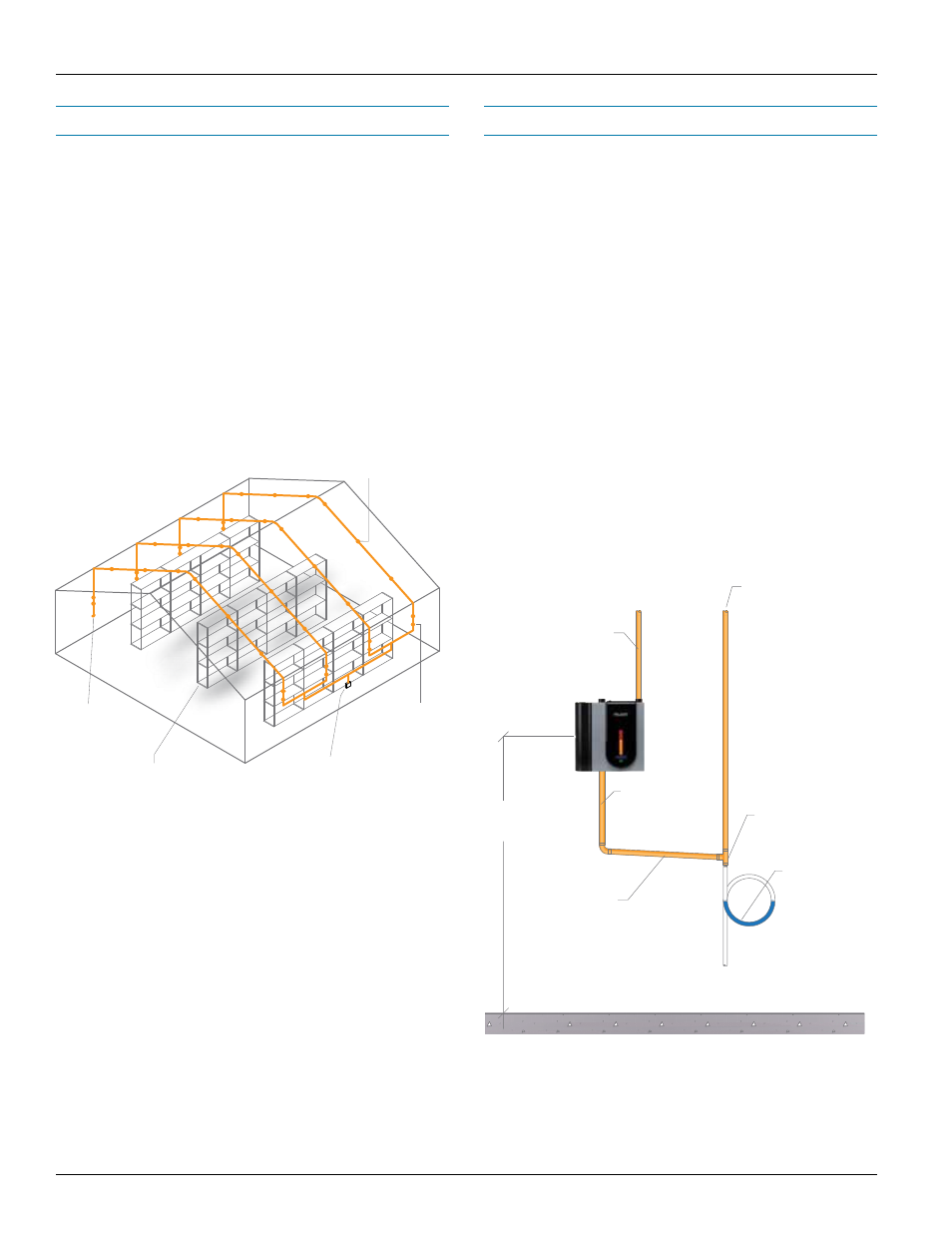

Large Area Protection

Large volume areas and areas with high ceilings require

special design considerations for the pipe network design.

Stratification occurs when smoke is heated by smoldering

or burning materials and becomes less dense than the

surrounding cooler air. The smoke rises until there is no longer

a difference in temperature between the smoke and the sur-

rounding air (see NFPA 72-2013 A.5.7.1.10). Stratification,

therefore, may occur in areas where air temperature may be

elevated at the ceiling level, especially where there is a lack of

ventilation. When stratification is likely to occur, conventional

pipe network sampling may not be effective.

One method to overcome smoke stratification is to create

vertical sampling pipes in addition to the horizontal pipe

network on the ceiling. The vertical sampling pipe should

have sampling ports at various heights to sample within any

stratification layers present in the area, as shown in figure 20.

Frequently Asked Question – Does FAAST eliminate

stratification issues?

No, stratification occurs when smoke cools to a temperature

equal to the surrounding air. To overcome the effects of

stratification, provide sample ports on the pipe as it runs

vertically up the wall. It is recommended to provide sample

ports for stratification when the ceiling height exceeds 30 ft.

or when ceiling elevations transition, creating a jet stream.

Cold Area Protection

The FAAST detector is approved for operating temperatures

ranging from 32°F (0°C) to 100°F (38°C) and sampled air

temperature form -4°F (-28°C) to 140°F (60°C). However,

special considerations should be taken when operating at the

extreme end of these ranges.

The temperature in a cold area is typically at or just above

freezing. In designing a pipe system, the pipes should be kept

out of the immediate airflow from a chiller unit, if used, as its air

is often significantly colder than the room itself. Sample ports

should also be located away from frequently used doors

where possible.

Often, the temperature of the cold room is outside the operating

temperature of FAAST and the device must be mounted outside

of the room with the pipe network being run in to the protected

space. Depending on the temperature of the air being removed

from the room, heating elements may be required, and a

condensation trap installed to catch any condensation or

moisture that may enter the device.

For more information on deploying FAAST in cold storage

applications, see the cold storage white paper at

systemsensor.com/faast.

Air sampling test port

located at the end of

each branch pipe -Typ.

Air sampling ports on

vertical pipe to capture

smoke stratification -Typ.

Air sampling ports on

air sampling network -Typ.

FAAST Detector

Stratification Layer

of Smoke

Figure 20: Large area protection.

Figure 21: Cold area protection.

Exhaust pipe back to

area being monitored

From air sampling network,

run additional horizontal piping

after exiting cold area. Sample

air temperature must be above

-4°F (-20°C) before entering

the detector.

Install drip loop on tee

fitting prior to entering

detector.

Always maintain water

halfway of drip loop.

To nearest drain or

condensate collector.

Piping shall be pitched

accordingly based on

the natural flexibility the

pipe will allow.

Maintain a

minimum of 16 in.

of vertical pipe.

FAAST Detector shall be

mounted 5 ft.- 0 in. AFF.