High air exchange areas – System Sensor Pipe Installation User Manual

Page 16

User Guide: Aspirating Smoke Detector Pipe Installation

16

Generally the FAAST detector should not monitor more than

two air handling units. When monitoring multiple units with one

device, the AHUs should have similar flow at all times. The

number of air handlers monitored is limited by the maximum

length of the pipe network. However, the degree of particle

dilution and air movement that occurs with multiple air handlers

can adversely affect system response times. Final system

testing should be done to confirm actual response times.

High Air Exchange Areas

Typically, high air exchange areas have some form of

mechanical ventilation to maintain constant or cyclical air

flow for heating, cooling or maintaining some other sort of

special environment. Smoke tends to travel with the air flow, so

positioning sampling pipes near the return of an air handling

unit or heating/air conditioning unit ensures early detection of

particulate in the area.

Normal sampling methods for high air exchange areas are a

combination of return air and ceiling sampling. The return air

sampling provides protection when the air flow is present. The

ceiling network provides protection when the air flow is off.

Local codes typically require smaller sample areas (closer

spacing of sample ports) as the air flow rate increases.

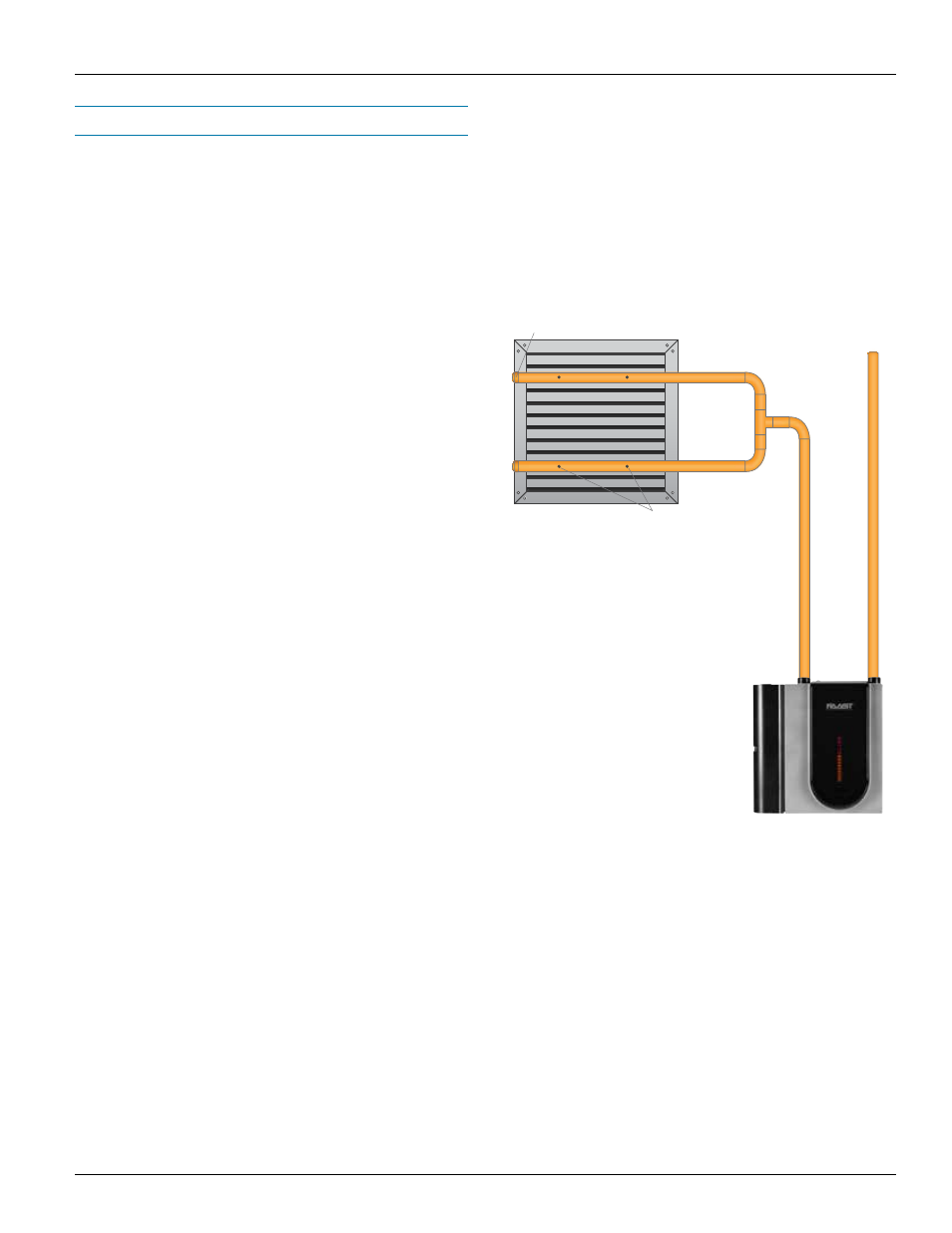

Return Air Sampling

Return air sampling provides an effective means of Very Early

Warning in a high air velocity environment. Placing the pipe

network sampling ports directly in the air stream at a return

air grill allows the system to monitor air that has circulated

throughout the protected area.

The following guidelines should be reviewed and followed to

ensure proper sampling by the detector system:

1. More than one sampling location may be required for large

air grills. NFPA 76 recommendations specify that each

sampling port can cover a maximum of 4 sq. ft. (0.4 m

2

)

2. Sampling ports should be aligned at an angle of 20 to 45

degrees to the direction of the maximum air flow.

3. Sampling pipes should be placed in the path of the

greatest air flow.

4. The number of bends in the pipe network should be kept

to a minimum.

5. Pipe ends should be capped with an end cap. Depending

on the pipe design and PipeIQ recommendations, the end

caps may or may not have a sampling port.

6. Socket unions should be used in locations where the pipe

network requires the removal of the pipes on a regular

basis for maintenance purposes.

7. Use of standoff fittings to keep the pipe network at least 2"

to 8" (50 mm to 200 mm) in front of the grill for high velocity

air flow locations. Installing the network any closer to the

input grill locates the sample port in an area of negative air

pressure.

8. Always keep in mind that the monitored environment

should still ensure coverage even if the manufactured air

flow gets disrupted.

Figure 22: Return air sampling.

End cap

4ft. x 4ft.

Intake

Sample Ports

• NFPA calls for 4 sq. ft. max

per sample port

• Pipes to be positioned on 2-8"

stand-offs from grill opening

• Ports to be positioned 20" - 45"

into the direction of air flow