In-duct sampling, Design considerations for in-duct sampling, Small duct sampling – System Sensor Pipe Installation User Manual

Page 17

User Guide: Aspirating Smoke Detector Pipe Installation

17

In-Duct Sampling

The FAAST detector is approved for in duct applications.

National and local safety standards and codes recognize the

ability of air duct systems to transfer smoke, toxic gases, and

flame from area to area. Sometimes smoke can be of such

quantity as to be a serious hazard to life safety unless blowers

are shut down and dampers are actuated. The primary purpose

of duct smoke detection is to prevent injury, panic, and property

damage by reducing the spread (recirculation) of smoke.

Duct smoke detection also can serve to protect the air

conditioning system from fire and smoke damage, and can

be used to assist in equipment protection applications, for

example, in the ventilation/exhaust duct work of mainframe

computers and tape drives. For additional information relating

to duct applications, refer to the duct application white paper

at systemsensor.com/faast.

Design Considerations for In-Duct Sampling

The following guidelines are necessary to obtain the best

installation results.

1. Pipes should always be supported at both duct walls –

rubber grommets can be used. Silicon sealer must also

be used to ensure an airtight seal in the duct walls.

2. Inlet pipes must be inserted between six and ten

duct widths or diameters (for round ducts) from any

disturbances to the flow generated by sharp bends,

plenums, nozzles, branch connections, etc…

3. Sampling ports should be located no closer than 2” to

the duct wall.

4. Ports on the inlet pipe should face 20-45 degrees into the

air flow with the ports concentrated at the center of the

duct as shown in figure 22.

5. The exhaust pipe must have 4, 3/8" (9.5 mm) ports. Ports

should be concentrated in the middle of the duct’s width

and spaced evenly. Ports on the exhaust pipe should be

oriented such that they face away from the air flow.

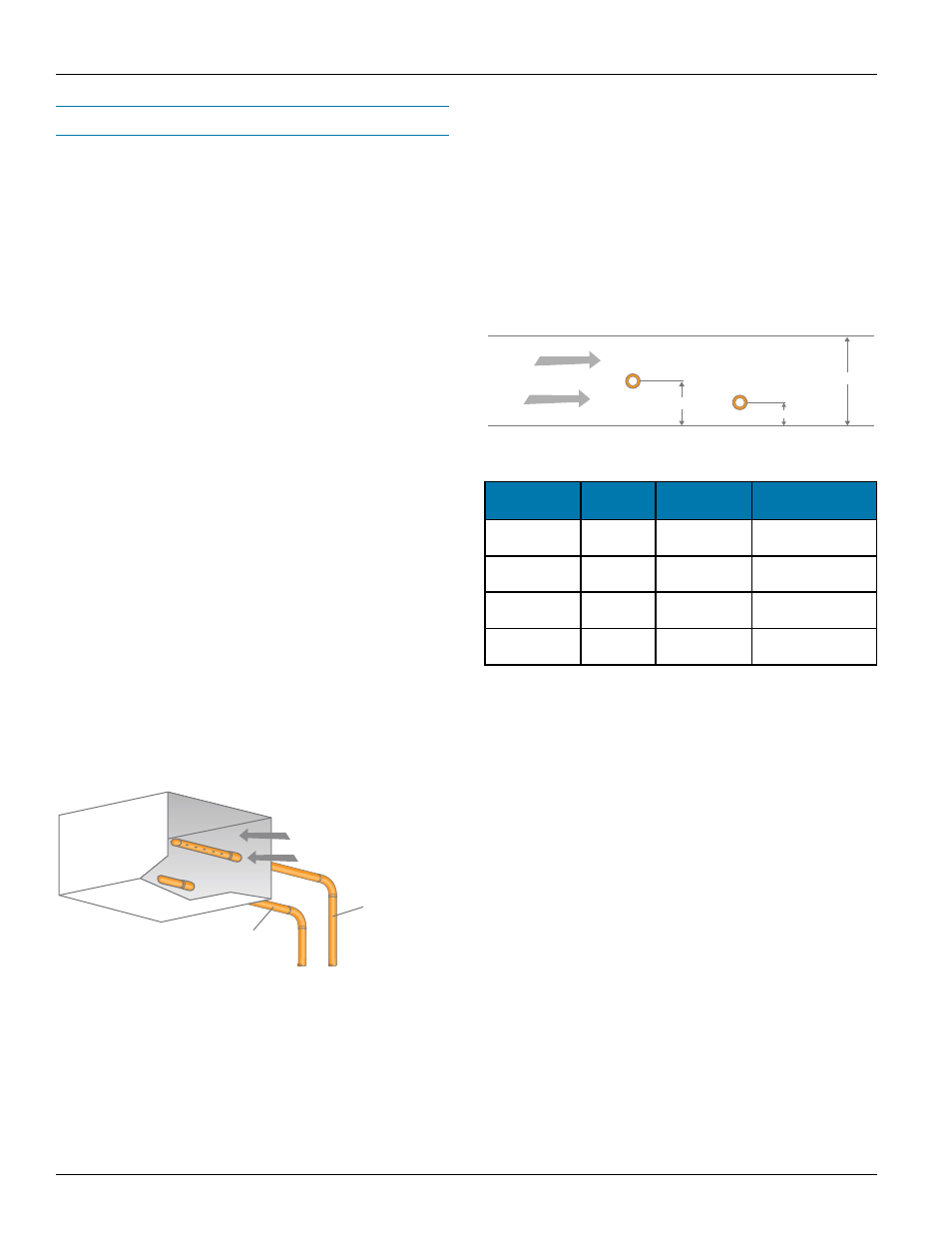

Small Duct Sampling

For ducts with a width less than 3 ft. (1 m), the inlet pipe should

be installed at the midpoint of the duct height or diameter.

Exhaust pipes should be inserted at 18" (0.5 m) downstream

from the input pipe. The exhaust pipe should be at one quarter

of the duct height or diameter, as shown in figure 23. To avoid

dilution, sampling pipes should be located before fresh air

intakes and before the exhaust air output.

Figure 23: Design considerations for in-duct sampling.

Figure 24: Small duct sampling.

Direction of

Air Flow

Air Supply to

FAAST Device

Exhaust Pipe from

FAAST Device

Inlet Pipe

H/2

Outlet Pipe

H

H/4

Air Flow

Small Diameter Duct

Duct Width

Number

of Ports

Port Size

Nominal Pipe

Flow Rate (CFM)

12 in.

(300 mm)

2

1/4 in.

(6.5 mm)

1.84 cfm

(52.0 L/min)

20 in.

(500 mm)

3

1/4 in.

(6.5 mm)

1.83 cfm

(51.9 L/min)

28 in.

(700 mm)

4

11/64 in.

(4.5 mm)

1.70 cfm

(48.1 L/min)

36 in.

(900 mm)

5

5/32 in.

(4 mm)

1.81 cfm

(51.2 L/min)

Table 4: Port sizes for small ducts.