Operation cleaning and maintenence – Sunex Tools SX10A User Manual

Page 5

SX10A: Parts Breakdown & Operating Manual

5

rev. 04/29/06

SPRAY GUN

1. Submerge the front end of the gun in solvent just until the

fluid connection is covered.

2. Paint that has built up on the gun should be removed using a

bristle brush and solvent.

3. Never submerge all of the spray gun in solvent because:

• This will dissolve the lubricant in the leather packings and

on wear surfaces, causing them to dry out and resulting in

difficult operation and faster wear.

• Air passages in the gun will become clogged with dirty

solvent.

4. Using a rag moistened with solvent, wipe down the outside of

the gun.

5. Oil gun daily. Use a drop of lightweight machine oil on:

A. fluid needle packing

B. air valve packing

C. trigger pivot point

(trigger side of gun)

D. side port control packing

See Fig. 1 for Location of Above Points.

6. NOTE: Do not soak rubber o-rings

or seals in paint thinner. O-rings and

seals can be wiped clean with paint

thinner but soaking can cause these

items to deteriorate over time.

7. Caution: Do not use lubricants which

contain silicone. Silicone may cause

defects in the finish application.

on material and atomizing pressure. For a uniform finish, lap each

stroke over the preceding stroke, making sure the spray is smooth

and wet.

Using the lowest possible atomizing air pressure will reduce

overspray and provide maximum efficiency.

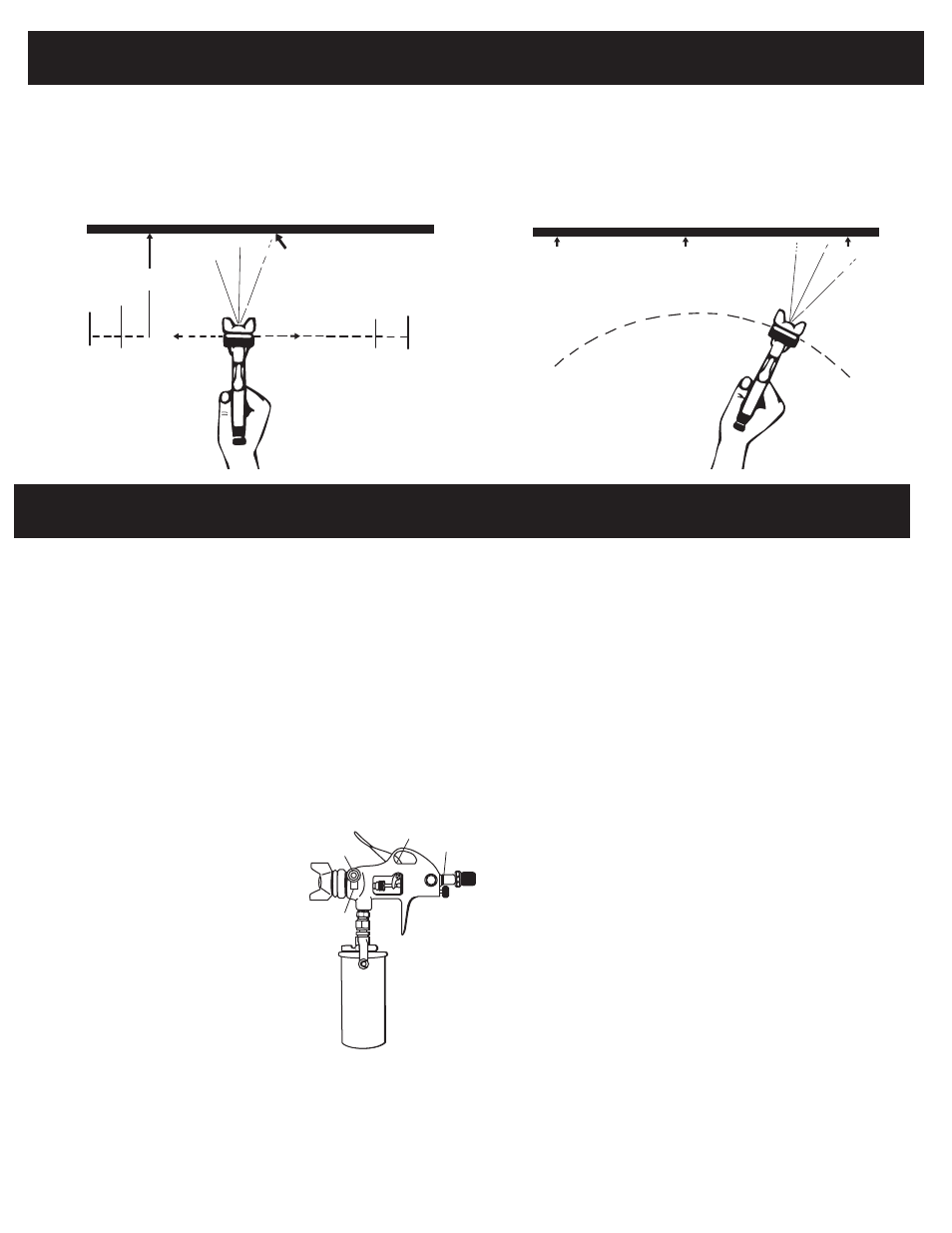

Proper handling of the gun is essential for obtaining a good finish. The

gun should be held at a right angle to the surface being covered, and

moved parallel with it. For precise control of the gun and material, the

trigger should be released before the end of the stroke.

Hold the gun from 6 to 12 inches away from the surface depending

CAUTION…

To avoid cross-threading, all spray gun parts should be screwed in

hand tight initially. If the parts can not easily be turned by hand , be

sure you have the correct parts, unscrew, realign, and try again.

NEVER use excessive force in matching parts.

AIR NOZZLE, FLUID NOZZLE, AIR VALVE ASSEMBLY

1. All nozzles and needles are made to exact standards. They

should be handled carefully.

2. To clean nozzles, immerse them in solvent until any dried

material is dissolved, then blow them clean.

3. Do not use metal or sharp instrument to probe any of the holes in

the nozzles.

4. Air flow should occur before fluid-flow when the gun is triggered.

It may be necessary to adjust the fluid control screw to make

sure air flows before fluid.

5. Do not alter the gun in any way.

SIPHON CUP

Turn off air supply. Disconnect cup from lid. Raise tube out of

material and pull trigger to allow remaining material to drain back

to the cup. Empty the cup of material. Clean the cup, lid and tube.

Add some thinner to cup. Reassemble. Turn on air supply and spray

with proper cleaning solvent. Repeat with clean solvent if necessary.

Remove solvent, disconnect gun, remove air cap and clean. Wipe gun

and cup with rag dampened with solvent.

OPERATION

CLEANING AND MAINTENENCE

Fig. 1

Light Coat

Heavy Coat

WRONG

Start

stroke

Pull

trigger

Release

trigger

End of

Stroke

RIGHT

Even and wet coat

6 to 12 inches

A

B

C

D