Air supply, Types of installation, Drain air lines properly – Sunex Tools SX10A User Manual

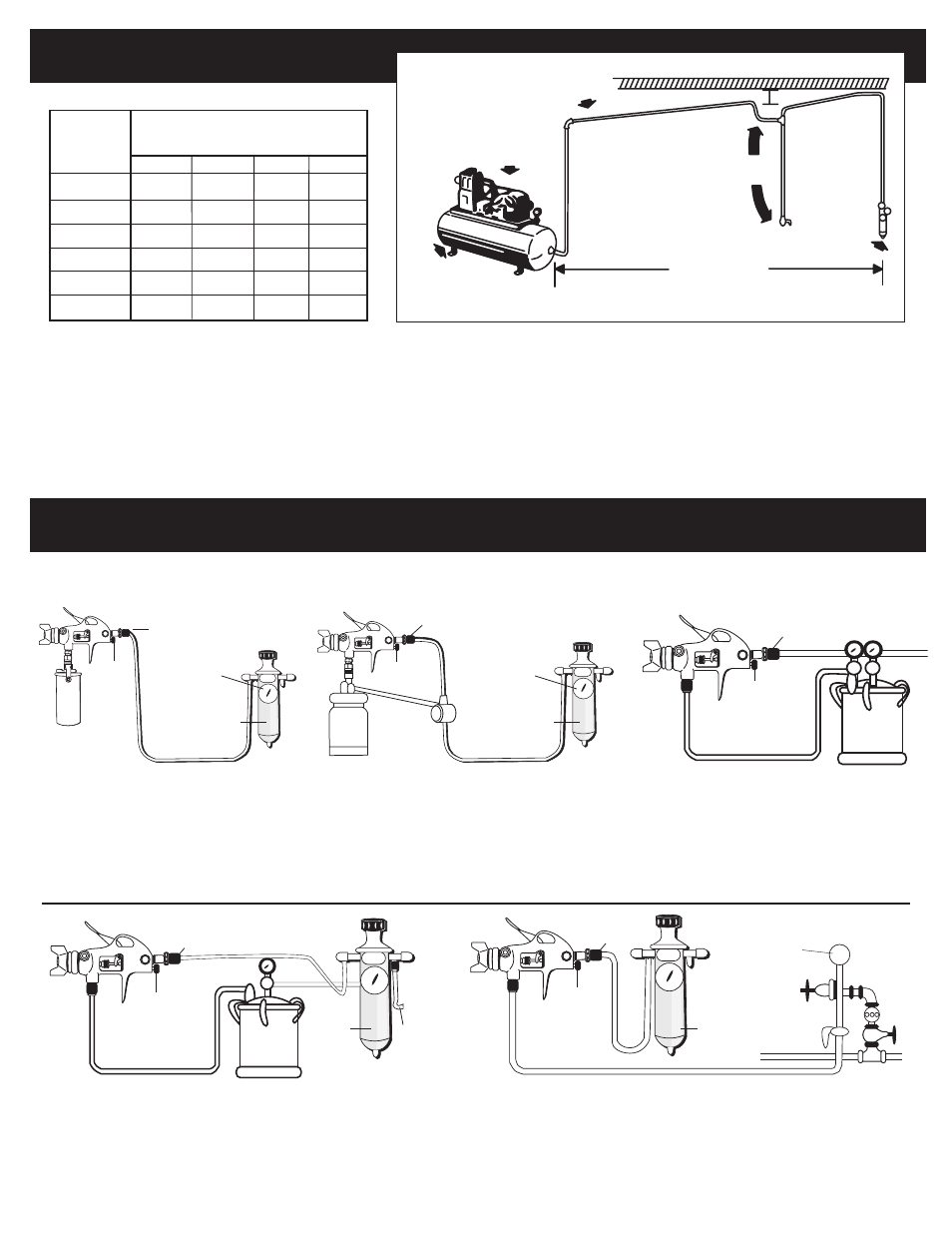

Page 3: Siphon feed cup hookup, Pressure feed cup hookup, Pressure feed tank hookup, Pressure feed circulating hookup

SX10A: Parts Breakdown & Operating Manual

rev. 04/29/06

Never mount oil and water extractor on or near the air compressor.

During compression, air temperature is greatly increased. As the air cools down to room temperature, moisture condenses in the air line, on

its way to the spray gun. Therefore, always mount the oil and water extractor at a point in the air supply system where the compressed air

temperature is lowest.

Drain air lines properly.

Pitch all air lines back towards the compressor so that condensed moisture will flow back into the air receiver where it can be drained off.

Each low point in an air line acts as a water trap. Such points should be fitted with an easily accessible drain. See diagram above.

Length of Pipe (ft.)

Air

Flow

CFM 50

100

150

200

10

20

30

40

50

70

1/2"

3/4"

3/4"

1"

1"

1"

3/4"

3/4"

3/4"

1"

1"

1"

3/4"

1"

1"

1"

1-1/4"

3/4"

3/4"

1"

1"

1"

1-1/4"

This spray gun is rugged in construction, and is built to yield exceptional value. The life of this product and the efficiency of its

operation depend upon a knowledge of its construction, use and maintenance.

SIPHON FEED CUP HOOKUP

Air pressure for atomization is regulated at

extractor. Amount of fluid is adjusted by fluid

control screw on gun, viscosity of paint, and

air pressure.

PRESSURE FEED CUP HOOKUP

For fine finishing with limited spraying. Air pressure

for atomization is regulated at extractor; fluid

pressure at cup regulator. For heavy fluids and

internal mix nozzle spraying, fluid adjusted by

control screw on gun.

AIR SUPPLy

Air Hose

Oil & Water

Extractor

Drain

Oil and Water Extractor should be at least 25 ft.

from the compressor, farther if possible.

25 Feet

or More

Install drain at

each low point

Compressor Unit

Pitch pipe back

toward air receiver

Drain

TyPES OF INSTALLATION

PRESSURE FEED TANK HOOKUP

(Double regulator)

Air pressure for atomization and fluid supply is

regulated by two individual air regulators on tank.

PRESSURE FEED TANK HOOKUP

(Single Regulator)

Air pressure for atomization is regulated

at extractor, fluid pressure at tank regulator.

PRESSURE FEED CIRCULATING HOOKUP

For fine finishing with limited spraying. Air pressure for atomization is regulated

at extractor; fluid pressure at cup regulator. For heavy fluids and internal mix

nozzle spraying, fluid adjusted by control screw on gun.

Fluid Siphon Cup

Air Inlet

Fluid

Control

Screw

Atomization

Pressure

Gauge

Oil and Water

Extractor

Air Hose

Fluid Siphon Cup

Air Inlet

Fluid Control

Screw

Atomization

Pressure

Gauge

Oil and Water

Extractor

Fluid

Pressure

Tank

Air Inlet

Fluid

Control

Screw

Air

Supply

Fluid

Pressure

Tank

Air Inlet

Fluid

Control

Screw

Air

Extractor

Main

Line

Outlet

Fluid

Air Inlet

Fluid

Control

Screw

Extractor

Air

Fluid

Regulator

Fluid