Ss actuator, Load on the actuator, Connecting the controller – IAI America SSCR User Manual

Page 10

Page 8

SS Actuator

7.3 Clamp Screws

• The screws for mounting the base should be M5 for SS-Small (S) Type, and M8 for the SS-Medium (M)

Type (use hexagon sockets).

• For the bolts, we recommend high strength bolts of ISO- 10.9 or higher.

• Make sure the bolt and screw engagement length is the following value or greater:

Steel screw

à same length as the nominal diameter

Aluminum screw

à twice as long as the nominal diameter

• When attaching the base to a mounting table, use the special washer made for high strength bolts that comes

with the actuator if the bolt is M8 or larger. This is unnecessary for M6 or smaller bolts. Do not use a

common spring washer.

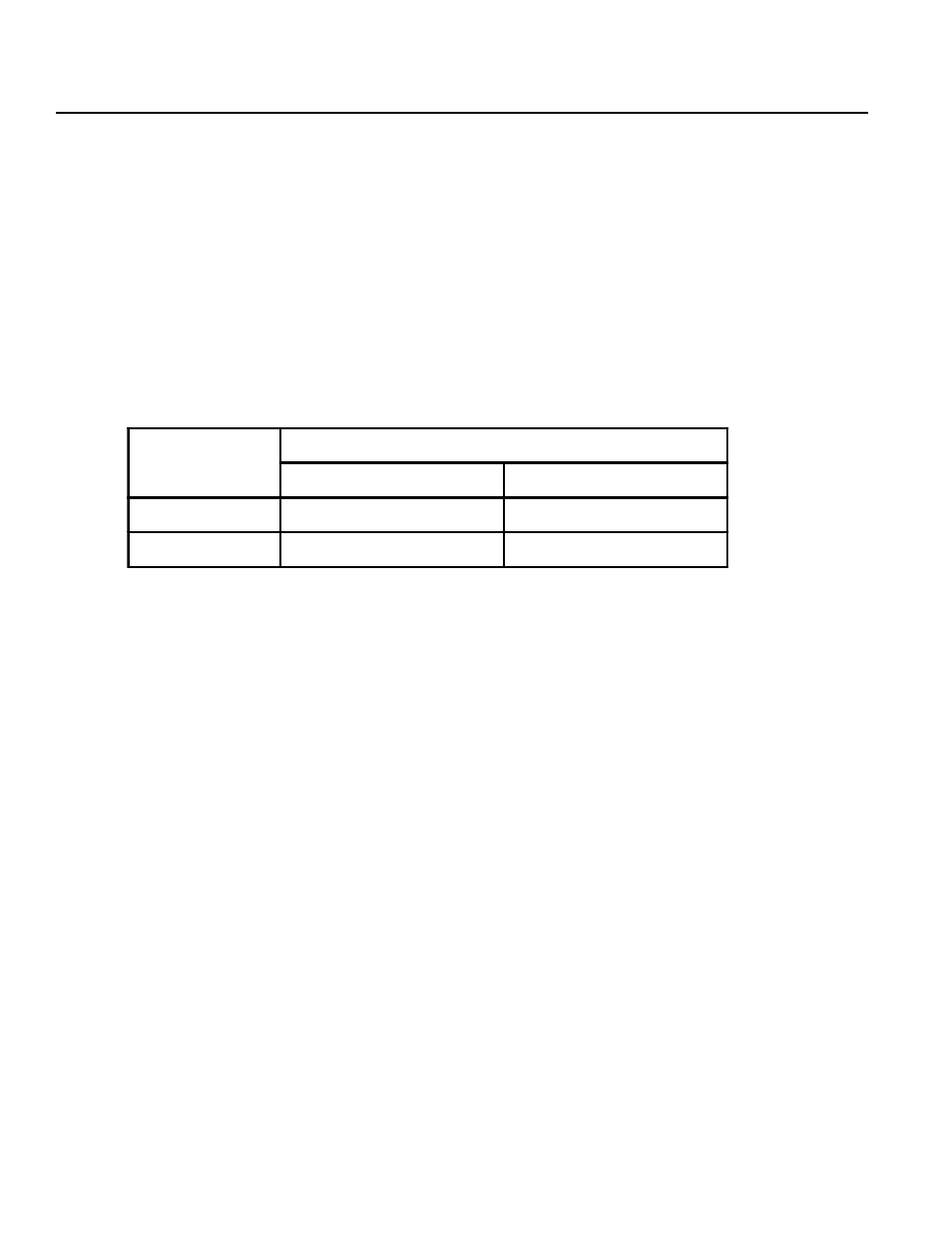

• The recommended screw torque is given to the diagram below.

9. Load on the Actuator

Do not exceed the load shown in the load specification column. Please make note of the slider moment, allowable

overhang length and the load weight. The body of the base warps easily when you use the actuator with the

Y-axis overhanging. Please use the actuator so that the Ma and Mc moments are less than 1/2 of the rated value.

8. Connecting the Controller

We will explain the controller wiring for a single axis actuator.

8.1 Standard Wiring Specifications

For a single axis actuator, unless otherwise specified we attach a standard 3 meter cable (5 meter option) to the

actuator when we ship the unit. Please attach the cable end directly to the controller.

• Although we use cable that is resistant to bending fatigue, it is not robot cable. Please avoid housing the cable

in a wire duct with a small bending radius.

• In an application where the cable cannot be anchored, try to place the cable where it will sag only under its

own weight or use dedicated cable hose for large radius wire duct to limit the load on the cable.

• Do not cut the cable to lengthen, shorten, or reconnect it.

• Do not pull on the cable or use excessive force to bend it.

If you wish to alter the cable, please consult with IAI before doing so.

Screw Nominal

Diameter

Clamping Torque

When the rod surface is steel

When the rod surface is aluminum

M5

7.7N

•

m (0.77kgf

•

m)

4.4N

•

m (0.44kgf

•

m)

M6

31.9

•

m (31.9kgf

•

m)

14.3N •m (1.43kgf

•

m)