HTP PHR199-55C User Manual

Page 31

31

LP- 325 REV. 3.21.14

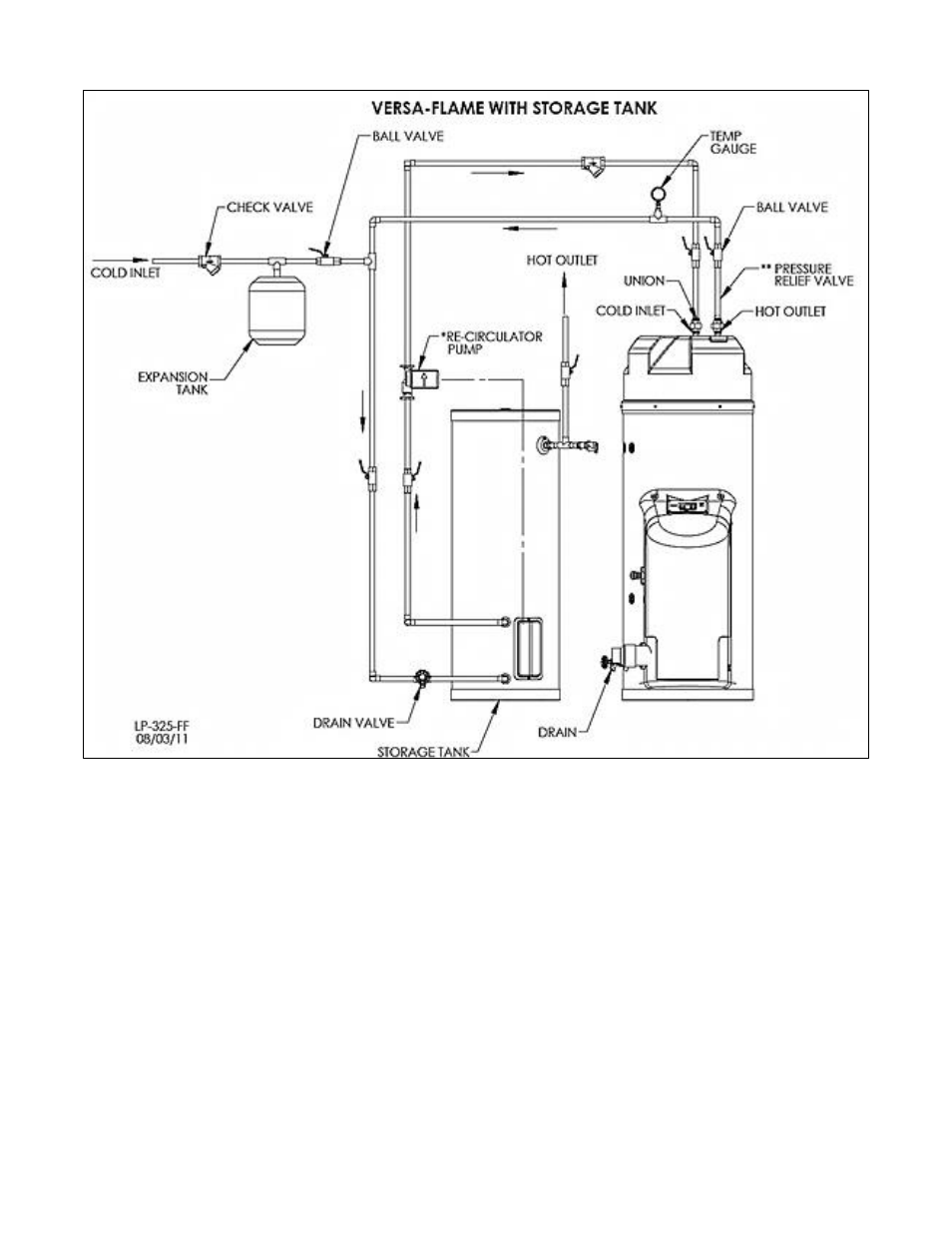

Figure 12

– Versa-Flame with Storage Tank NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119°F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. A pressure relief valve or T&P valve may be required. Check with local codes.

5. This drawing refers to DHW piping only. For Central Heating piping, please refer to Part 5, Section L.

6. Winterization: When winterizing, pump a small amount of food grade glycol, FDA rated as GRAS (Generally Recognized As Safe) into the brazed

plate heat exchanger.

7. In Massachusetts, a vacuum relief valve must be installed on the cold water line per 248 CMR.

8. Recirculator pump must be sized to flow 0.6 GPM or greater to the appliance.

9. If a backflow preventer or no return valve is installed, a thermal expansion tank is required on the cold water inlet between the water heating appliance

and the backflow preventer.

10. Versa-Flame DHW setting on mixing valve must be set higher (5

o

F minimum) than storage tank set point.