HTP PHR199-55C User Manual

Page 30

30

LP- 325 REV. 3.21.14

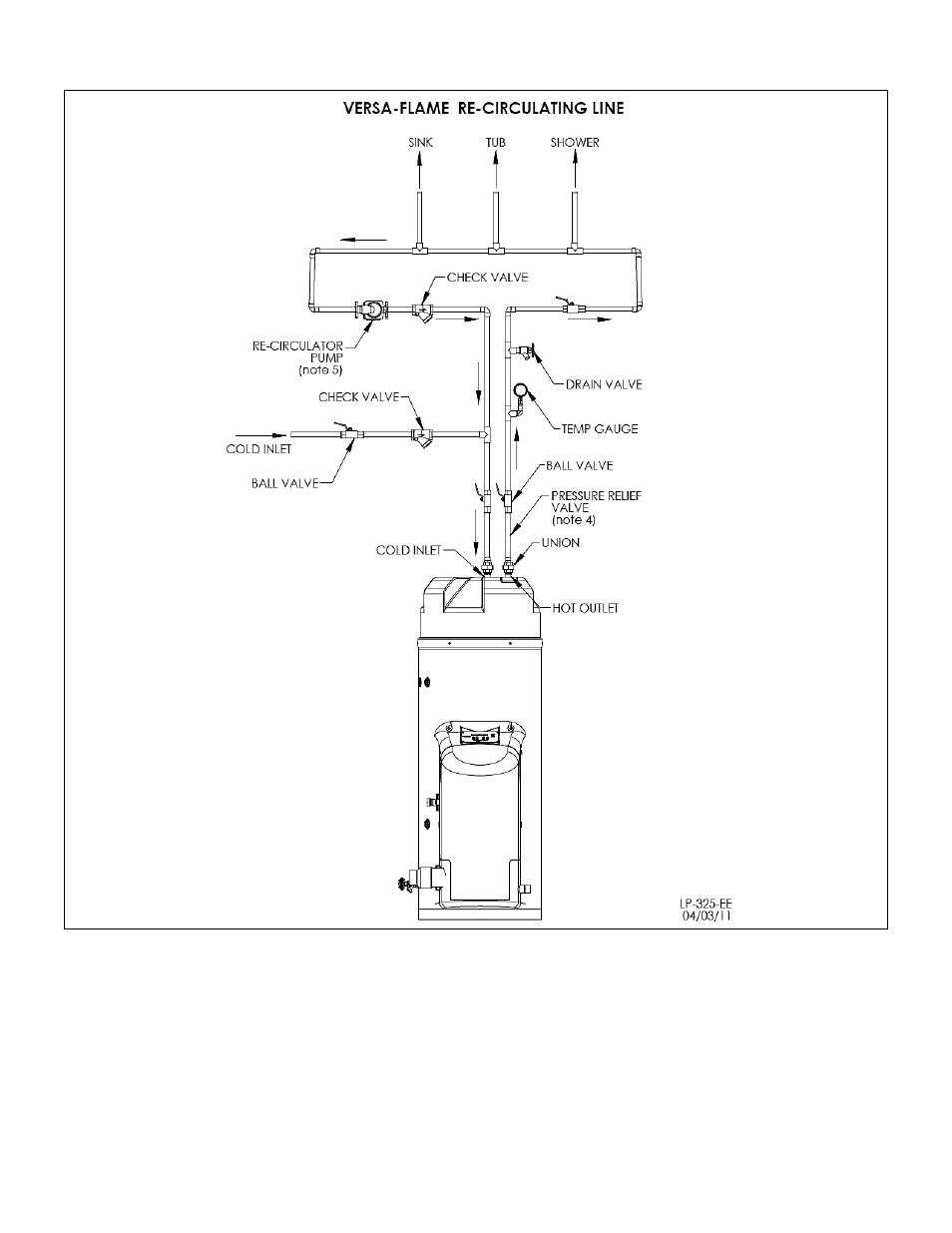

Figure 11

– Versa-Flame with Re-Circulating Line

NOTES:

1. This drawing is meant to show system piping concept only.

Installer is responsible for all equipment & detailing required by local codes.

2. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119°F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. A pressure relief valve or T&P valve may be required. Check with local codes.

5. This drawing refers to DHW piping only. For Central Heating piping, please refer to Part 5, Section L.

6. Winterization: When winterizing, pump a small amount of food grade glycol, FDA rated as GRAS (Generally Recognized As Safe) into the brazed

plate heat exchanger.

7. In Massachusetts, a vacuum relief valve must be installed on the cold water line per 248 CMR.

8. Recirculator pump must be sized to flow 0.6 GPM or greater to the appliance.