Harrington Hoists and Cranes (G)NTH Trolley User Manual

Page 31

31

6.1.4

Trolley:

Lubricate the following trolley components with NLGI (National Lubricating Grease Institute) #2 or

equivalent grease.

Track Wheel Gear

– Clean and re-grease the Track Wheel gears and Hand Wheel output pinion

every three months (more frequently for heavier usage or severe conditions). Do not use an

excessive amount of grease and avoid getting any grease on the running surfaces of the Track

Wheels or the beam.

Trolley Wheel Bearings do not need to be lubricated and must be replaced if worn or damaged.

Suspension Pins, Bolts and Shafts

– Grease at least twice per year for normal usage (more

frequently for heavier usage or severe conditions).

6.2

Disassembly, Assembly and Adjustment

6.2.1

1) Perform proper disassembly or assembly in accordance with this manual.

2) The hoist utilizes dry friction plates; they are not to be lubricated.

3) Do not extend the load chain.

4) Remove old grease on the disassembled parts.

5) Replace components with Harrington Hoist approved parts.

6) To reassemble, apply new grease, and use a new split pin and snap ring.

6.2.2

Tools

– The following tools are required to disassemble/reassemble the hoist.

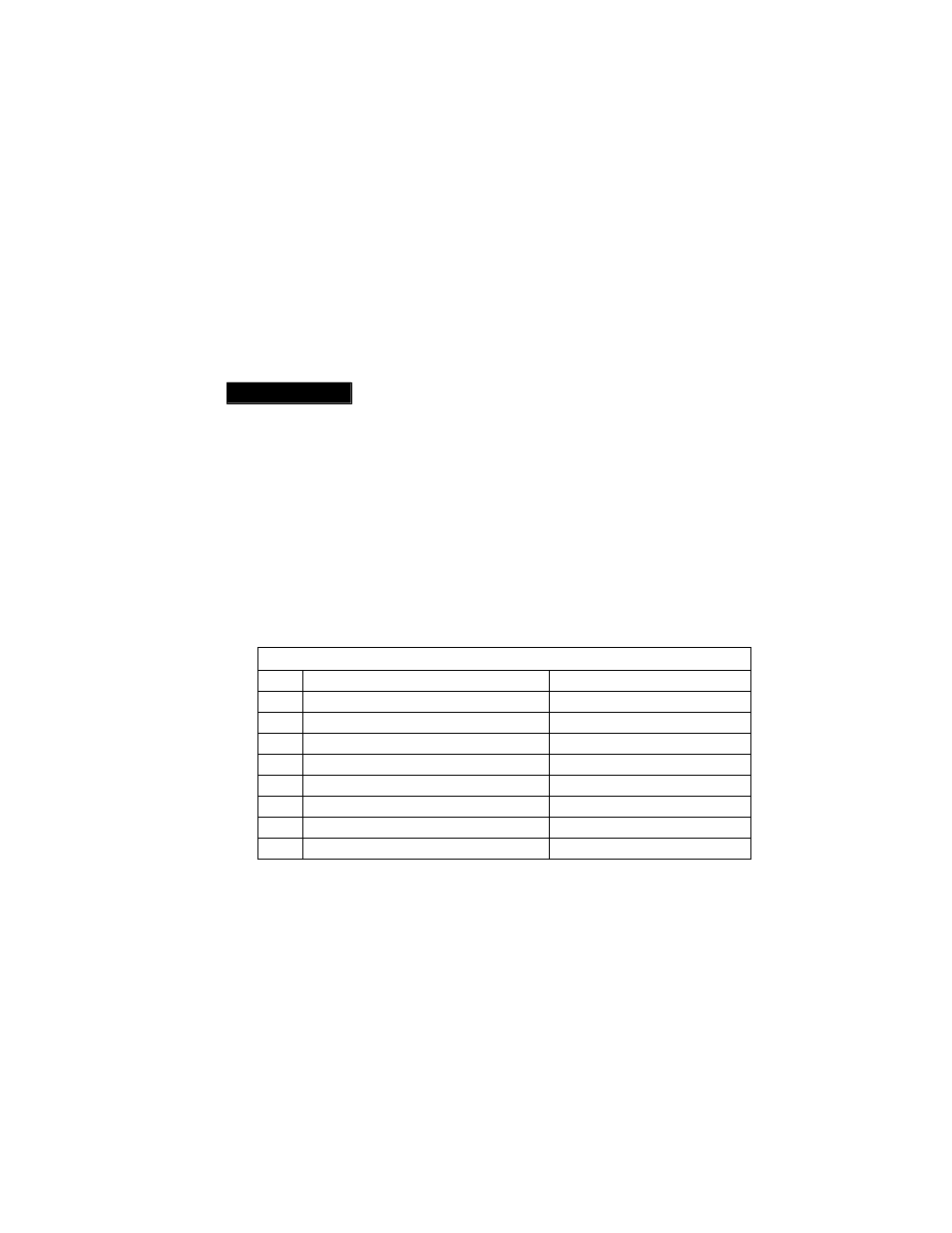

Table 6-2 Tools Required for Hoist Disassembly

No.

Tool

Operation

1

Snap ring pliers

Opening a snap ring

2

Metric socket wrenches

Slotted nuts

3

Metric hex keys (Allen wrenches)

Socket head cap screws

4

Metric wrenches

Bolts and nuts

5

Phillips screwdriver

Machine screws

6

Pliers (Needle Nose)

Split pins

7

Soft-face (Dead blow) hammer

8

Wooden Blocks

Elevate hoist

6.3

Hoist Disassembly

Proceed as follows (Note: Figures in brackets are Figure Numbers in Parts List):

1) Orient a hoist with wheel cover side up.

2) Unscrew three screws [38] (with spring washers [39]) that attach the wheel cover [37].

3) Remove the wheel cover [37] from the body A [10].

4) Insert a vertical link of the hand chain [43] into the notch of the hand wheel [33] and remove the

hand chain by turning the hand wheel counterclockwise.

NOTE: Bring the notch of the hand wheel to the right hand side.